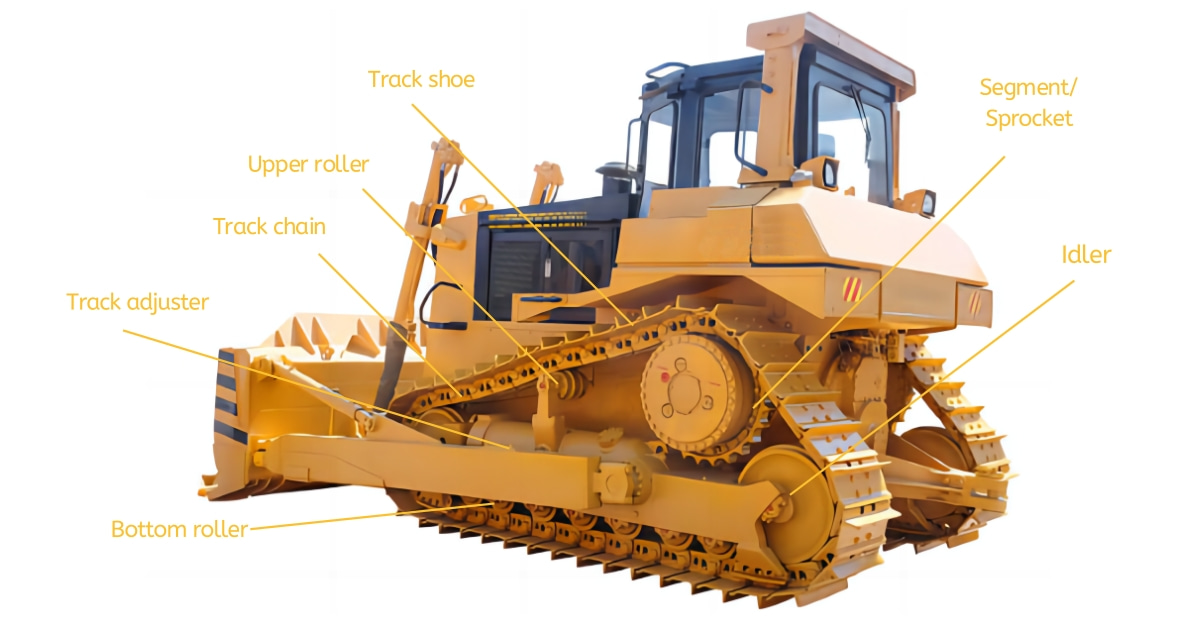

Dozer Undercarriage Parts

Designed to meet the highest industry standards, our Sprocket Segment Group is specifically crafted for heavy-duty machinery in the ever-evolving world of manufacturing and construction. Engineered with utmost precision, it guarantees seamless and efficient workflow, ensuring optimal productivity.

Crafted from premium-quality materials, this Sprocket Segment Group boasts unparalleled durability, guaranteeing prolonged operational lifespan, even under the most demanding conditions. Its robust construction enables it to withstand the harshest environments, providing unwavering reliability.

| Material | 50MnB Steel |

| For Machine Type | Bulldozer |

| Manufacture Technique | Forging / Casting |

| Surface Hardness | 56 - 62HRc |

| OEM/ODM Customize | Supported |

| Warranty time | 2000 Hrs |

| Model | OEM Part No. |

| D8K/D8H | 6T6782 sprocket segment fit for CAT D8K dozer |

| D7G | 6T4178 sprocket segment |

| D6H | 6Y2931 sprocket segment |

| D6C/D6D | 8P5837 sprocket segment |

| D5H | CR5513 sprocket segment |

| D5 | 6Y5244 sprocket segment |

| D4H | 6Y5245 sprocket segment |

| D4D | 4V4107 sprocket segment |

| D3C | 9W9266 sprocket segment |

| D8N/D8R | 6Y2354 sprocket segment |

| D20/D21 | 101-98-00050 sprocket segment fit for komatsu dozer |

| D30/D31 | 113-27-31320 sprocket segment |

| D50 | 131-27-61710 sprocket segment |

| D60/D65-8 | 141-27-32410 sprocket segment |

| D65EX-12 | 14X-27-15111 sprocket segment |

| D80/D85 | 155-27-00151 sprocket segment |

| D155 | 175-27-22324 sprocket segment |

| D355 | 195-27-12466 sprocket segment |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported