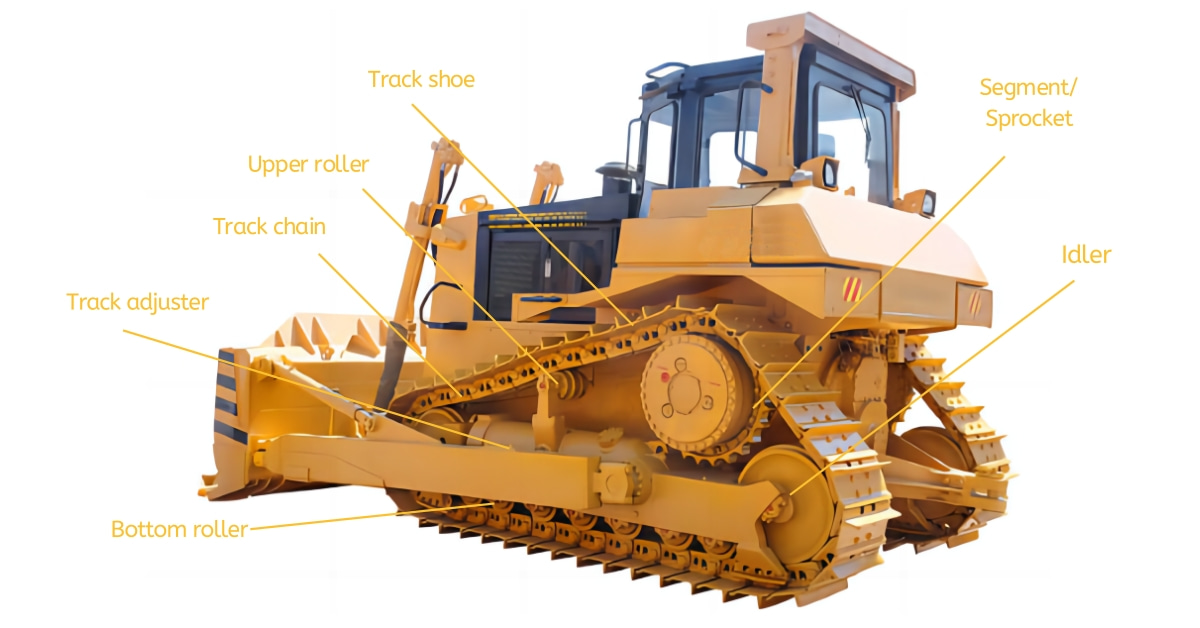

Dozer Undercarriage Parts

We stock track chain to fit the smallest excavator to the largest D11N Cat Dozer. Track chains and track groups are available to fit all makes and models of excavators and dozers.Track chains are also available for other tracked machinery.

Types of Dozer Track Chains – Dry Chains vs. Lubricated Chains

When considering dozer track chains, there are two primary types: dry chains and lubricated chains. Dry chains have a lower initial cost compared to lubricated chains and are effective at keeping dirt and debris out, thereby reducing wear from contaminants. However, they require regular external lubrication to minimize wear, and without lubrication, the friction between pins and bushings can lead to faster wear. On the other hand, lubricated chains offer internal lubrication, which reduces friction and wear, resulting in a longer lifespan and lower maintenance compared to dry chains. They are ideal for heavy-duty applications where maintenance intervals are longer. The disadvantages of lubricated chains include a higher initial cost and the potential for seal failure over time, which can lead to the loss of internal lubrication.

Click on the product name to enter the product page. For more products, please use the search function in the top right corner of the page.

D10N Track Chain Assembly D6K Dozer Track Chain D85 Dozer Track Links

D9N Dozer Track Group D375A-5 Track Group D10N Dozer Track Group

1、Introduction:

We offer two types of dozer track chain:

Greased Track Chain (dry chains)

Oil Lubricated Track Chain (Lubricated Chains)

Excavator chains are grease filled and sealed for extended wear life. Polyurethane seals prevent abrasive materials from entering the internal pin & bush therefore reducing wear.

For dozer and other demanding applications, KASU-PARTS stock a range of sealed and lubricated track (SALT) chains with oil filled lubricant which reduces internal friction and extends wear life.

Our range supports a wide array of models from the world’s leading manufacturers.

Dozer track chain is also available for other tracked machinery and applications such as cranes, haulers, apron feeder conveyers and elevating scraper.

2、The following are partial part numbers for bulldozer track chains, for reference.

| Model & Part Number | Dozer Track Chain BERCO Number | Links | Pitch |

| D3C 6Y1713 | CR4749/39 | 39L | 155 |

| D4D 7K2372 | CR2567/40 | 40L | 171 |

| D4E 1V7072 | CR3628/36 | 36L | 171 |

| D5 5S0816 | CR2823/39,CR5035/ | 39L | 175 |

| D5B 3P3885 | CR3520/39 | 39L | 175 |

| D5B 953 7T4637 | CR4264/4040 | 40L | 175 |

| D4H 6Y5407 | CR5192/39 | 39L | 171 |

| D5H 6Y5412 | CR5202/37 | 37L | 190 |

| D6D 963 9W8843 | CR4267/36 | 36L | 203 |

| D6C 225 229 6P6131 | CR3176/36,CR5059/ | 36L | 203 |

| D6H 6Y5417 | CR4810A/40 CR6587 | 40L | 203 |

| D6R 6I9670 | CR5534/40 | 40L | 203 |

| D7 977K 1S6943 | CR1769/41 | 41L | 203 |

| D7G 235B 8S2607 | CR2567/38,CR5061 | 38L | 216 |

| 973 9W9167 | CR4700/40 | 40L | 216 |

| D7H 6Y1141 | CR5069/40 | 40L | 216 |

| D8K 2P9492 | CR3149/41 | 41L | 228 |

| D8R 8E4518 | CR4525/44 | 44L | 216 |

| D9H 8S1731 | CR2672/39 | 39L | 260 |

| D10R 2389851 | CR6075/44 | 44L | 260 |

| D20-6,7 102-32-00032 | KM906/37 | 37L | 135 |

| D31P-18,20 11G-32-00025 | KM727/41 | 41L | 154 |

| D61X-12 13G-32-00020 | KM2868/46 | 46L | 190 |

| D65-8 141-32-00045 | KM953/39 | 39L | 203 |

| D65 144-32-00054 | KM951/37 | 37L | 203 |

| D65 141-32-00065 | KM951/39 | 39L | 203 |

| D65PX-15 14Y-32-00110 | KM3467/45 | 45L | 203 |

| D85SS-2 14U-32-00010 | KM2094/42 | 42L | 203 |

| D85-21 154-32-00400 | KM1103/39 | 39L | 216 |

| D85EX-15 154-32-00620 | KM3904/41 | 41L | 216 |

| D155 175-32-00103 | KM325/41 | 41L | 228 |

| D275A-5 17M-32-00400 | KM3593/39 | 39L | 260 |

| D355A-5 195-32-00105 | KM596/39 | 39L | 260 |

| D375A-5 195-32-00591 | KM3599A/40 | 40L | 280 |

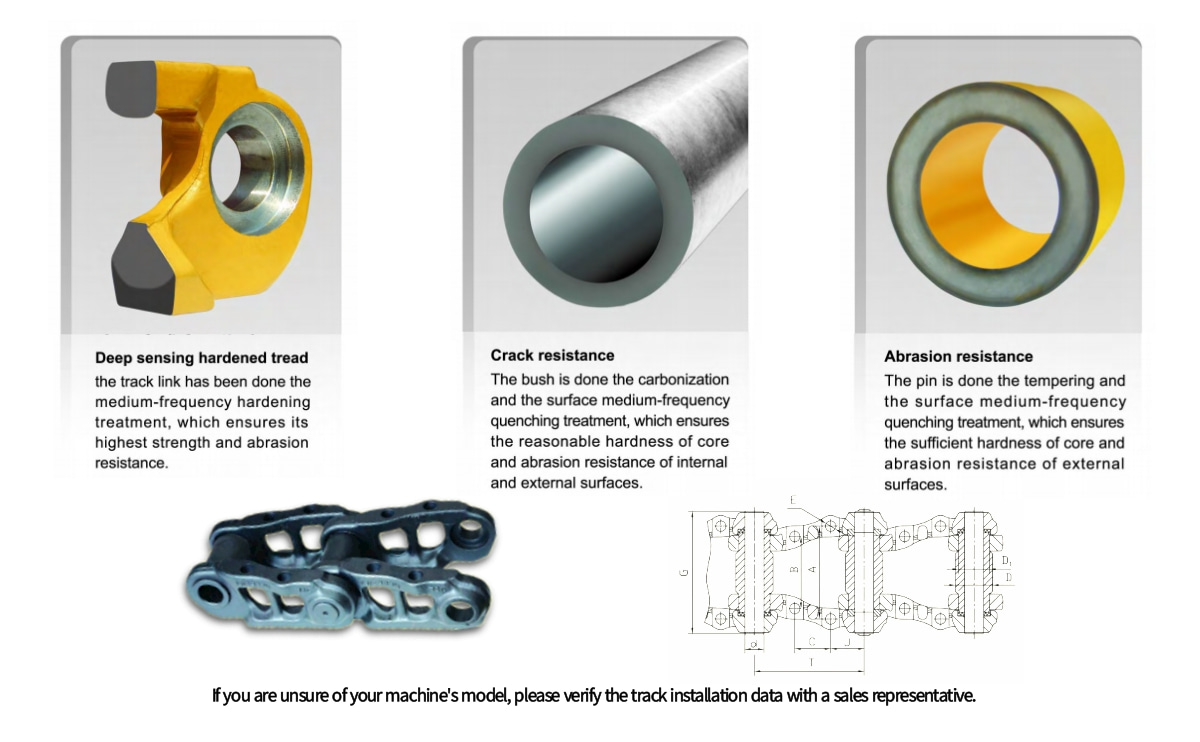

3、Bulldozer Track Chain Key Features:

3、FAQ

Terms & Conditions of Ordering:

① Payment Terms: T/T (Telegraphic Transfer)

② Delivery Term: Based on order quantity, normally it takes 25 days for production. Only 2 or 5 days if we have stock on your request size.

③ Transportation: Sample order: we suggest Courier express or by air. Bulk order: we suggest by air or by sea.

④ Quality & Service:

A. There will be strict inspection and testing for every order before shipping out.

B. Our sales team and Technical Support will response for your question within 24 hours (Holidays Excluded) through WhatsApp/Wechat: + 86 18850110101

Maintaining the proper tension in your dozer track chains is crucial for optimal performance. Ensuring your tracks are neither too loose nor too tight will help prevent functional issues. Regular reference to your manual for the correct tension settings is recommended, and adjustments should be made as necessary to maintain this optimal tightness.

Moreover, selecting the appropriate track shoes for different job sites can significantly impact your machine’s performance. Depending on the type of movement your machinery will be doing and the terrains you’ll be working on, choosing the right track shoes helps enhance traction and reduce wear. This selection is vital for maintaining efficiency and extending the lifespan of your tracks.

In addition to tension and shoe selection, it is important to regularly inspect for signs of wear on the idlers. Deep pockets or grooves on the idler surface, along with the formation of a lip on the edge, are indicators that servicing may be required. These signs of wear can affect the overall performance and efficiency of your dozer.

Keeping the undercarriage clean and well-lubricated is another key aspect of maintenance. The buildup of dust, mud, and debris can hinder lubrication and make your equipment more difficult to operate. This additional strain can lead to more forceful maneuvers, causing further wear and tear. Regular cleaning ensures that your undercarriage remains in good condition, facilitating smoother operation.

Lastly, frequent inspections are invaluable. Conducting thorough inspections with the operator’s manual in hand allows you to spot wear, damage, and other issues before they escalate into more significant and costly repairs. Daily visual inspections are recommended to keep your machinery in top shape and ready for work.

By integrating these maintenance practices into your routine, you can extend the service life of your dozer track chains, reduce lifetime costs, and ensure your equipment operates efficiently on the worksite. Regular and proactive maintenance is key to maximizing productivity and minimizing downtime.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported