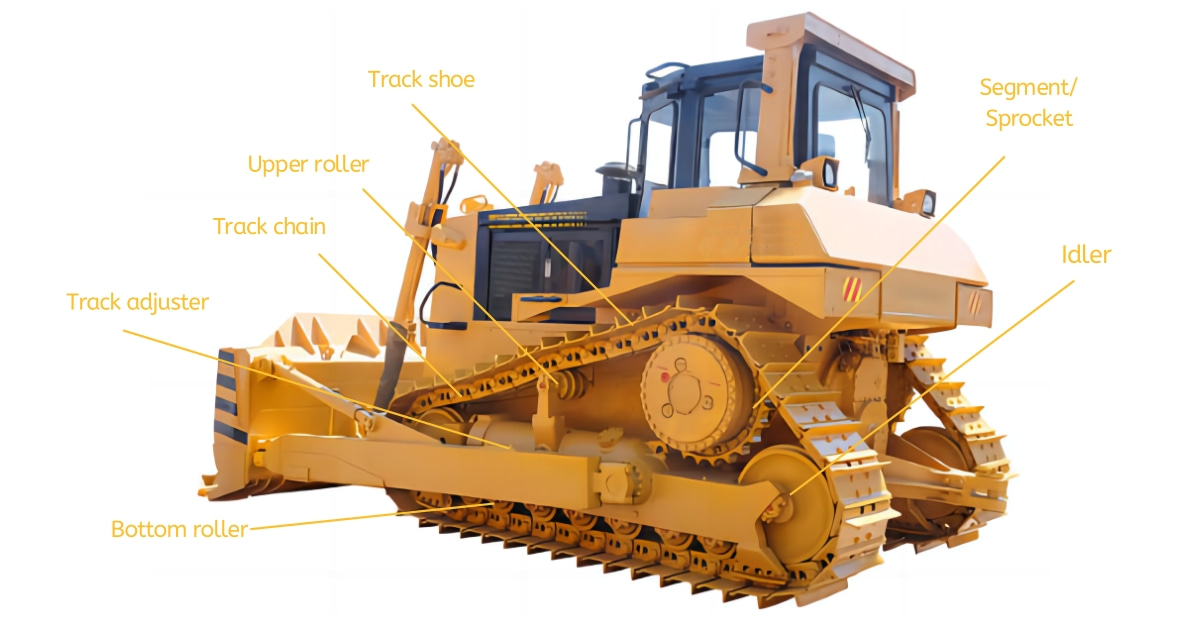

Dozer Undercarriage Parts

As a professional manufacturer of bulldozer undercarriage parts, we specialize in producing high-quality bulldozer track group consisting of the track shoes and track chains. Our bulldozer track groups are designed and manufactured using premium materials and advanced production techniques to ensure durability and performance. The track shoes are made of high-strength steel and hardened to resist wear and tear, while the track chains are made of alloy steel and heat-treated for maximum strength and resistance to stretching.

We are a professional manufacturer of bulldozer undercarriage parts,click on the product name or use the search function in the top right corner to learn more.

D6K Bulldoze Track Group D375A5 Dozer Track Group D10N Track Group

Contact Information:

1、instroduction:

Our bulldozer track group are meticulously crafted with an unwavering focus on optimal performance. We take pride in the superior quality of our products, and each component within our track groups reflects this commitment.

Starting with the track shoes, we select only the finest materials, ensuring durability and resilience in the face of tough terrains and heavy workloads. These track shoes are designed to withstand the harshest conditions and provide exceptional traction.

Additionally, our bolt and nut assemblies are of the highest quality, meticulously manufactured and tested to ensure they meet the stringent standards set by OEMs. This attention to detail extends to our track chains, which are forged from top-grade materials and subjected to rigorous heat treatment processes to enhance their strength and longevity.

What sets us apart is not only our dedication to product excellence but also our extensive product line. We offer track groups suitable for various bulldozer brands, including Caterpillar, Komatsu, and Sumitomo, among others. This versatility allows us to cater to a wide range of customer needs, making us a reliable choice for bulldozer track groups across different applications.

Despite our unwavering commitment to quality, we understand the importance of competitive pricing. We offer our exceptional track group at prices that remain competitive within the market. This means our customers can enjoy both the reliability of OEM-level products and the cost-effectiveness that comes with choosing our track groups.

In summary, our bulldozer track groups are a testament to quality, durability, and affordability. When you choose our products, you're not only opting for reliable and long-lasting solutions but also ensuring optimal performance for your bulldozer, regardless of the brand you operate.

For your convenience in searching and usage, we provide here some bulldozer track chain part numbers and a reference guide for common machine models. We hope this helps you.

2、Our service

Pre-sale support:

a. Develop customized projects based on client needs.

b. Create and manufacture products tailored to specific client requirements.

c. Provide training for technical personnel.

During-sale assistance:

a. Assist clients in selecting reliable freight forwarders in advance of delivery.

b. Aid clients in formulating problem-solving strategies.

Post-sale services:

a. Guide clients in preparing construction plans.

b. Oversee the installation and debugging of equipment.

c. Conduct training sessions for first-line operators.

d. Perform equipment inspections.

3、Dozer track chains part number

Part No. LINKS APPLICATION

1995531 42 D9R, D9T

3805946 43 D10T, D10T2

1061634 47 D5H, D5R LGP, D6M, D6N, D6N LGP

1061636 46 D5H, D5R LGP, D6M, D6N, D6N LGP

1080953 39 D4H

1080954 44 561M, 561N, D4H, D4H XL, D4HTSK III, D5M, D5N

1080955 41 D4H XL, D5M, D5N

1102976 40 D5R LGP, D6K LGP, D6K2, D6K2 LGP, D6M, D6N, D6N LGP, PL61

1156301 40 D7E, D7H, D7R, D7R II, D7R XR

1156302 43 572R, 572R II, D7H, D7R, D7R II, D7R XR

1156303 41 D7H, D7R, D7R II, D7R XR

1543657 40 D4E SR

1543672 39 951B, 951C, 561B

1543676 46 D5, D5B,

1543677 40 953, 953C

1995525 43 D9R, D9T

2279976 39 D5C III, D5G

2282744 44 D4H

2386930 46 D5H

2392230 38 D7G, D7G2

2726010 44 D8R, D8R II, D8T

2890270 40 D5K LGP, D5K2 XL

3238755 43 D3K2 LGP, D4K XL, D4K2 XL

3238757 39 D4D, D4E, D4E SR

3238759 37 931B, 931C, 935B, 935C, D3C

1V4599 36 D4D, D4E, D4E SR

1V7071 35 D4D, D4E

1V7074 38 941

1V7075 40 D4D, D4E

1V7077 41 955L

2S7579 40 561B, 951B, 955H

3P0628 39 977K, 977L

3P0955 38 571G, D7F, D7G, D7G2

3P0958 39 572G, 977K, 977L

3P1088 36 955K, 955L, D6C, D6D

3P1118 36 955K, 955L, D6C, D6D, D6D SR

3P1120 39 D6D, D6E, D6E SR, D6G SR

3P5757 39 951B, D5B

3P5927 40 D6C

6I8665 45 D8L

6I9668 39 D6H, D6R, D6R II, D6R III, D6T

6I9670 40 D6H XR, D6R, D6R II

6I9671 41 527, D6H XL, D6H XR, D6R, D6R II, D6R III, D6T, D6T LGP, D6T XL

6Y1139 43 D7H

6Y1141 40 D7H

6Y1711 36 D3B

6Y2887 47 D9L

6Y5412 37 D5H

7K2049 36 D4D, D4E

8E9037 45 D6H, D6H XL, D6R, D6R II, D6R III, D6T, D6T LGP, D6T XL

8S0396 41 D8H, D8K

9W8937 41 D8K

4、FAQ

Terms & Conditions of Ordering:

① Payment Terms: T/T (Telegraphic Transfer)

② Delivery Term: Based on order quantity, normally it takes 25 days for production. Only 2 or 5 days if we have stock on your request size.

③ Transportation: Sample order: we suggest Courier express or by air. Bulk order: we suggest by air or by sea.

④ Quality & Service:

A. There will be strict inspection and testing for every order before shipping out.

B. Our sales team and Technical Support will response for your question within 24 hours (Holidays Excluded) through WhatsApp/Wechat: + 86 18850110101

⑤Q: Can I place a small order initially?

A: Yes, certainly.

⑥Q: If we decide to change the size of the product, can you provide the seal kit for the new size?

A: Yes, just send us the machine model, part number, and the updated size details. We can make it for you.

⑦Q: Do you support OEM or not?

A: Certainly, we support OEM, or as per your requirements.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2025 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported

Hi! Click one of our members below to chat on