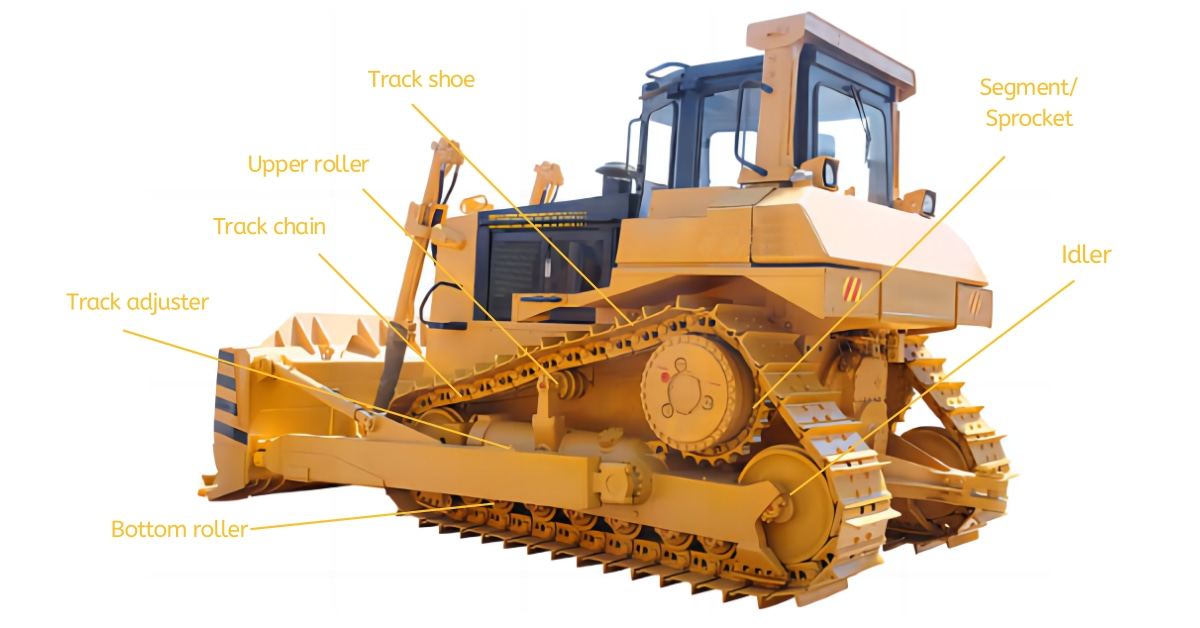

Dozer Undercarriage Parts

A Sprocket Segment For Bulldozer is a component of a bulldozer's undercarriage system. It is typically made of durable materials such as steel and is designed to help transfer power from the bulldozer's engine to its tracks, allowing it to move forward or backward.

1、The Importance of Timely Replacement of Bulldozer Sprocket Segment

It is important to timely replace the Sprocket Segment For Bulldozer because it is a critical component of the bulldozer's undercarriage system. Over time, the sprocket segment can become worn or damaged due to constant use, causing the teeth on the wheel to wear down and lose their grip on the track links. This can lead to decreased performance and efficiency, as well as increased wear and tear on the tracks.

If the sprocket segment is not replaced promptly, it can cause further damage to the undercarriage system and other components of the bulldozer. This can result in costly repairs and downtime, which can negatively impact productivity and profitability.

Regular inspection and replacement of the sprocket segment can help prevent these issues and ensure the bulldozer operates at peak efficiency and productivity. It is recommended to consult with a qualified technician or manufacturer for guidance on when to replace the sprocket segment, as this can vary depending on factors such as usage, operating conditions, and the type of sprocket segment used.

2、Why Choose Us

Firstly, our Sprocket Segment For Bulldozer are made of high-grade steel material that provides excellent wear and tear resistance, ensuring a longer lifespan for the product. This material also offers exceptional strength and durability, making it ideal for heavy-duty use in harsh working environments.

Secondly, our production process employs advanced manufacturing technologies and stringent quality control measures to ensure consistent product quality. Our skilled technicians use precision machining techniques to ensure precise dimensions and accurate fitting, minimizing downtime and maintenance costs.

Finally, our quality management system ensures that each sprocket segment is thoroughly inspected and tested for quality and performance before leaving the factory. This ensures that our products meet or exceed industry standards and customer expectations, providing optimal performance and reliability in the field.

3、Bulldozer Sprocket Segments Part Number:

| Model | OEM Part No. |

| D8K/D8H | 6T6782 sprocket segment |

| D7G | 6T4178 sprocket segment |

| D6H | 6Y2931 sprocket segment |

| D6C/D6D | 8P5837 sprocket segment |

| D5H | CR5513 sprocket segment |

| D5 | 6Y5244 sprocket segment |

| D4H | 6Y5245 sprocket segment |

| D4D | 4V4107 sprocket segment |

| D3C | 9W9266 sprocket segment |

| D8N/D8R | 6Y2354 sprocket segment |

| D20/D21 | 101-98-00050 sprocket segment |

| D30/D31 | 113-27-31320 sprocket segment |

| D50 | 131-27-61710 sprocket segment |

| D60/D65-8 | 141-27-32410 sprocket segment |

| D65EX-12 | 14X-27-15111 sprocket segment |

| D80/D85 | 155-27-00151 sprocket segment |

| D155 | 175-27-22324 sprocket segment |

| D355 | 195-27-12466 sprocket segment |

4、FAQ

Q1: What materials are used for your Bulldozer Sprocket Segments?

A: Our sprocket segments are crafted from high-quality steel materials, ensuring superior durability and performance.

Q2: Can you customize sprocket segments for specific machine models?

A: Absolutely, we provide customization. Share the machine model and any unique requirements, and we'll tailor the sprocket segments accordingly.

Q3: What production techniques ensure the quality of your sprocket segments?

A: We employ advanced production methods, including precision machining, heat treatment, and stringent quality control, to meet and exceed industry standards.

Q4: How do you ensure compatibility with different working conditions?

A: Our sprocket segments undergo robust testing to ensure they can withstand diverse and challenging working conditions, delivering reliability in every use.

Q5: What is the lead time for delivery?

A: If the product is in stock, we typically ship within approximately one week after receiving the deposit.

Q6: Do you provide a warranty for your Dozer Sprocket Segments?

A: Yes, we offer a warranty for our sprocket segments, providing you with confidence in the durability and quality of our products.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported