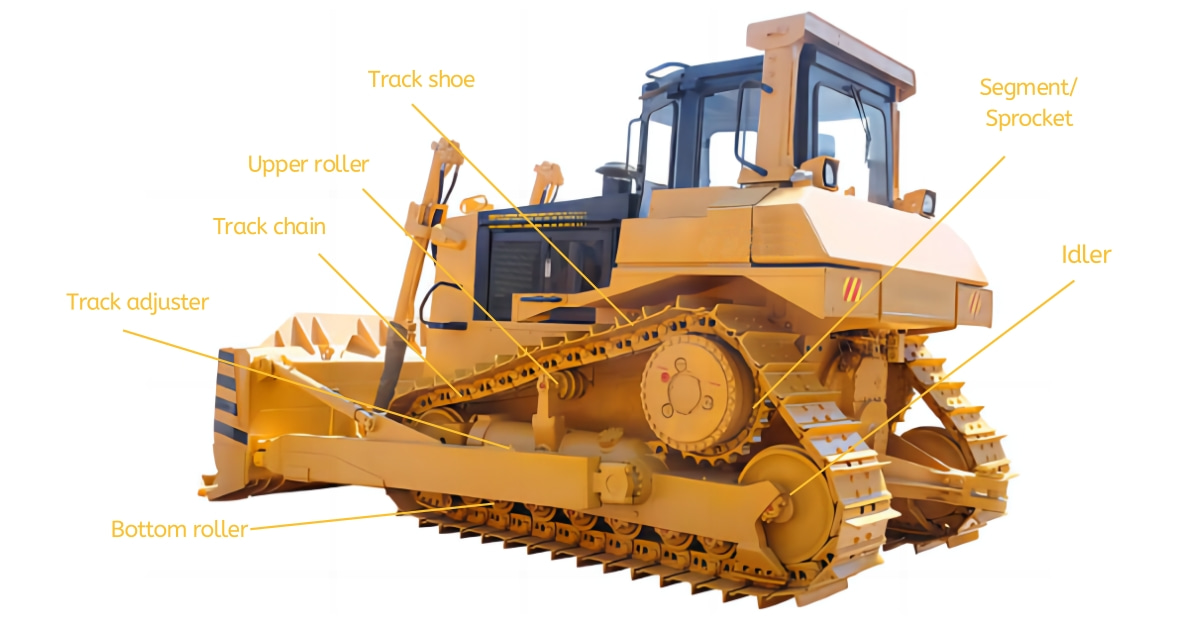

Dozer Undercarriage Parts

Crafted superior materials, our track pads boast exceptional hardness, ensuring longevity and minimal deformity even in the toughest terrains. With a refined production process and unwavering attention to quality, our track pads guarantee uncompromising performance. Elevate your bulldozer's capabilities with our reliable and durable solution.

| Material | 25MnB,25CrMnB |

| Colors | Black or Yellow |

| Processing | Forging, Casting, Machining, Heat treatment |

| MOQ | 1 set |

| Warranty | One Year |

| Shipping Port | XIAMEN |

| Delivery Time | Within 15-30 days after payments |

| Description | Length | Part Number | Model |

| TRACK SHOES 25” | 635mm | 198-6991 | D3G |

| TRACK SHOE 16” | - | 2063509 | D4E |

| MASTER SHOE 16” D4E | - | 2063517 | D4E |

| TRACK SHOE 20 D4H 8E | - | 9812 | D4H 8E |

| TRACK SHOES 20.1” | 510mm | 235-2554 | D5K |

| TRACK SHOE 560MM D6M | - | 1061607 | D6M |

| MASTER SHOE 560MM D6M | - | 1061613 | D6M |

| TRACK SHOE 22 ES D6R 6Y | - | 6389 | D6R 6Y |

| MASTER SHOE 22 ES D6R 6Y | - | 6412 | D6R 6Y |

| TRACK SHOE 915MM D6R | - | 1967839 | D6R |

| MASTER SHOE 915 6Y6302 D6R | - | 3P 1132 | D6R |

| TRACK SHOE 22 ES D8T | - | 3261136 | D8T |

| TRACK SHOE 24 ES D8T | - | 7T 2392 | D8T |

| TRACK SHOE 24 ES D9T | - | 7T 2294 | D9T |

| TRACK SHOE 24 ES D10T | - | 7T 724 | D10T |

| TRACK SHOE 28 ES D11T | - | 3105823 | D11T |

| TRACK SHOE 610 D65-15 | 610mm | 14X-32-11370 | D65-15 |

| TRACK SHOE 610 ES D85-15 | 610mm | 154-32-71390 | D85-15 |

| TRACK SHOE 610 ES D155-5 | 610mm | 175-32-31410 | D155-5 |

| TRACK SHOE 610 ES D275-5 | 610mm | 195-32-41112 | D275-5 |

| TRACK SHOE 610 ES D375-5 | 610mm | 195-32-61110 | D375-5 |

| TRACK SHOE 810 ES D457-5 | 810mm | 198-32-31540 | D457-5 |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported