| Material |

50Mn/40MnB |

| Finish |

Smooth |

| Colors |

Black or yellow |

| Technique |

Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness |

HRC48-54,deepth:4mm-10mm |

| Warranty time |

2000 hour |

| MOQ |

2 piece |

| Delivery Time |

Within 7-30 days after payments |

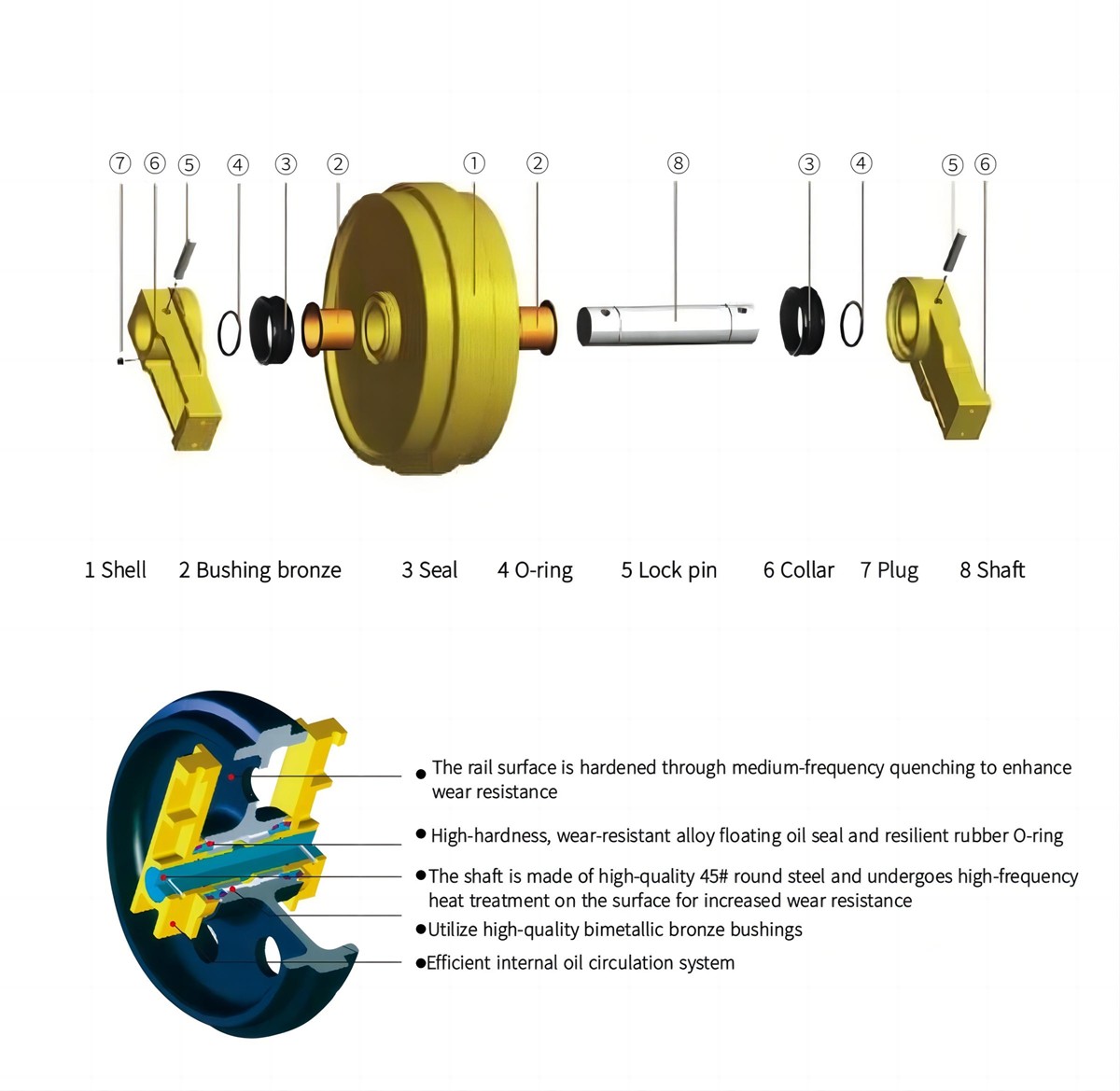

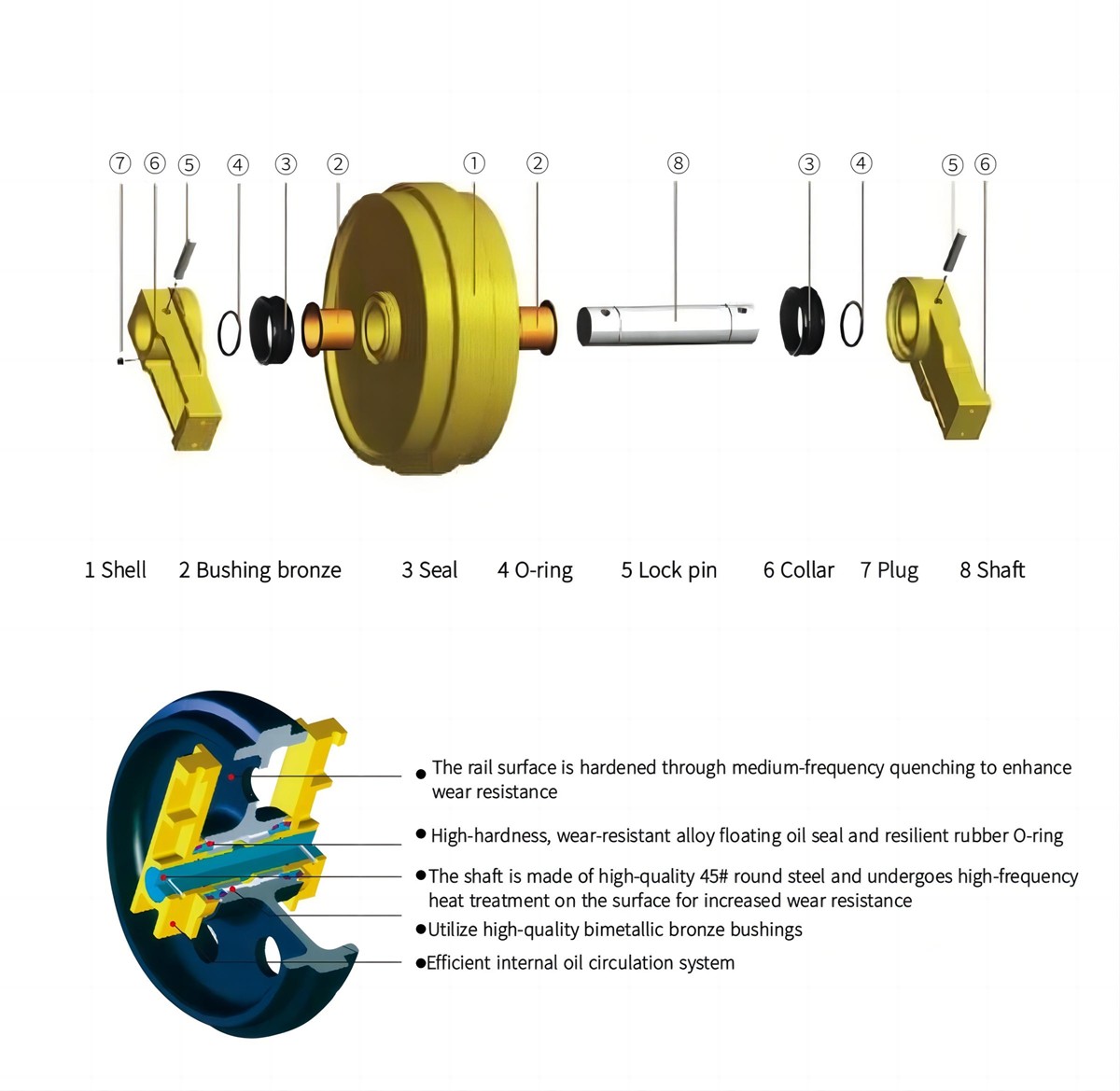

- Product Advantages:

1. Impeccable Material: Our Idler Dozer boasts a superior construction, utilizing only the finest quality of materials. Meticulously selected, these materials ensure unparalleled durability, strength, and longevity, guaranteeing optimal performance throughout its lifespan.

2. Rigorous Heat Treatment: With a strict regime of heat processing, every component of our Idler Dozer undergoes a thorough heat treatment. This meticulous process achieves a fine balance between hardness and toughness, resulting in exceptional performance, even under the most demanding working conditions.

3. Exemplary Quality Assurance: At every stage of the manufacturing process, each and every component of our Idler Dozer undergoes rigorous quality checks. Our unwavering commitment to providing reliable and high-quality products ensures that only the best components make their way into our Idler Dozer, ensuring a product of unmatched quality.

4. Unrivaled Performance: Designed to deliver optimal performance, our Idler Dozer surpasses all expectations. Its robust construction, combined with its superior material selection and precise engineering, offers exceptional reliability and longevity, allowing it to tackle the toughest terrains with ease.

5. Endurance and Dependability: Our Idler Dozer embodies the true essence of endurance and dependability. Whether it's handling heavy loads or enduring prolonged usage, it consistently delivers outstanding results. Its ability to withstand extreme conditions and continue performing flawlessly makes it a trusted companion in any challenging operation.

- Why Choose Us

1. Extensive Manufacturing Experience:

With years of hands-on experience in the industry, our skilled team brings extensive knowledge and expertise to the production of Idler Dozers. We have honed our manufacturing processes, continually improving efficiency and product quality.

2. Emphasis on Production Management:

We adopt a systematic and streamlined approach to production management, ensuring that every step, from raw material sourcing to final assembly, is carefully monitored and controlled. This dedication to efficient production management minimizes errors and ensures a smooth and timely delivery of our Idler Dozers.

3. Focus on Product Development:

Driven by innovation and market demand, we constantly invest in research and development to enhance our Idler Dozers' performance and durability. Our team of engineers and designers employ state-of-the-art technology and advanced techniques to create cutting-edge products that meet the evolving needs of our customers.

4. Commitment to Customer Service:

Customer satisfaction is at the core of our business. We strive to provide exceptional pre-sales and after-sales support, ensuring that our clients receive prompt answers to their inquiries, comprehensive product information, and timely assistance in resolving any issues. Our dedicated customer service team is always ready to go the extra mile to ensure a positive customer experience.

5. Care for Team Members:

We believe that a strong and united team is crucial for delivering outstanding products and services. We foster a positive work environment that values collaboration, professional growth, and employee well-being. By promoting a culture of respect, trust, and support, we empower our team members to excel in their roles and deliver exceptional results.

- Dozer Idler Part Number For Inference

Model OEM Part No.

D8N/D8R 9W9989 Front Idler

D9N/D9R 7T2769 Dozer Idler

D10N/D10R 7T0962 Bulldozer ldler

D20/D21 103-30-00120 Idler For Dozer

D30/D31 113-30-00102 ldler For Bulldozer

D50 131-30-00285 Idler Fit For Komatsu Dozer

D65-8 144-30-00038 Idler

D65-12 14X-30-00112 ldler

D85-18 154-30-00293 Idler

D85-21 154-30-00770 Idler

D155A-1 175-30-00575 Idler

D355A-3 195-30-00283 Idler

D3C 9N4173 Idler Fit For CAT Dozer

D4D/D4E 1M8867 Idler Fit For CAT Bulldozer

D4H 190-1534 Idler

D4H 190-1551 Idler

D5 CR3190 Idler

D5H 161-7549 Idler

D6C/D6D 7T4562 ldler

D6H/D6R 2024296 Idler

D6H/D6R 2024304 Idler

D7F/D7G 7T4509 Idler

D8K CR4096 Idler

D8N/D8R 9W9987 Idler

Network Supported

Network Supported