| Material |

50Mn/40MnB |

| Finish |

Smooth |

| Colors |

Black or yellow |

| Technique |

Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness |

HRC48-54,deepth:4mm-10mm |

| Warranty time |

2000 hour |

| MOQ |

2 piece |

| Delivery Time |

Within 7-30 days after payments |

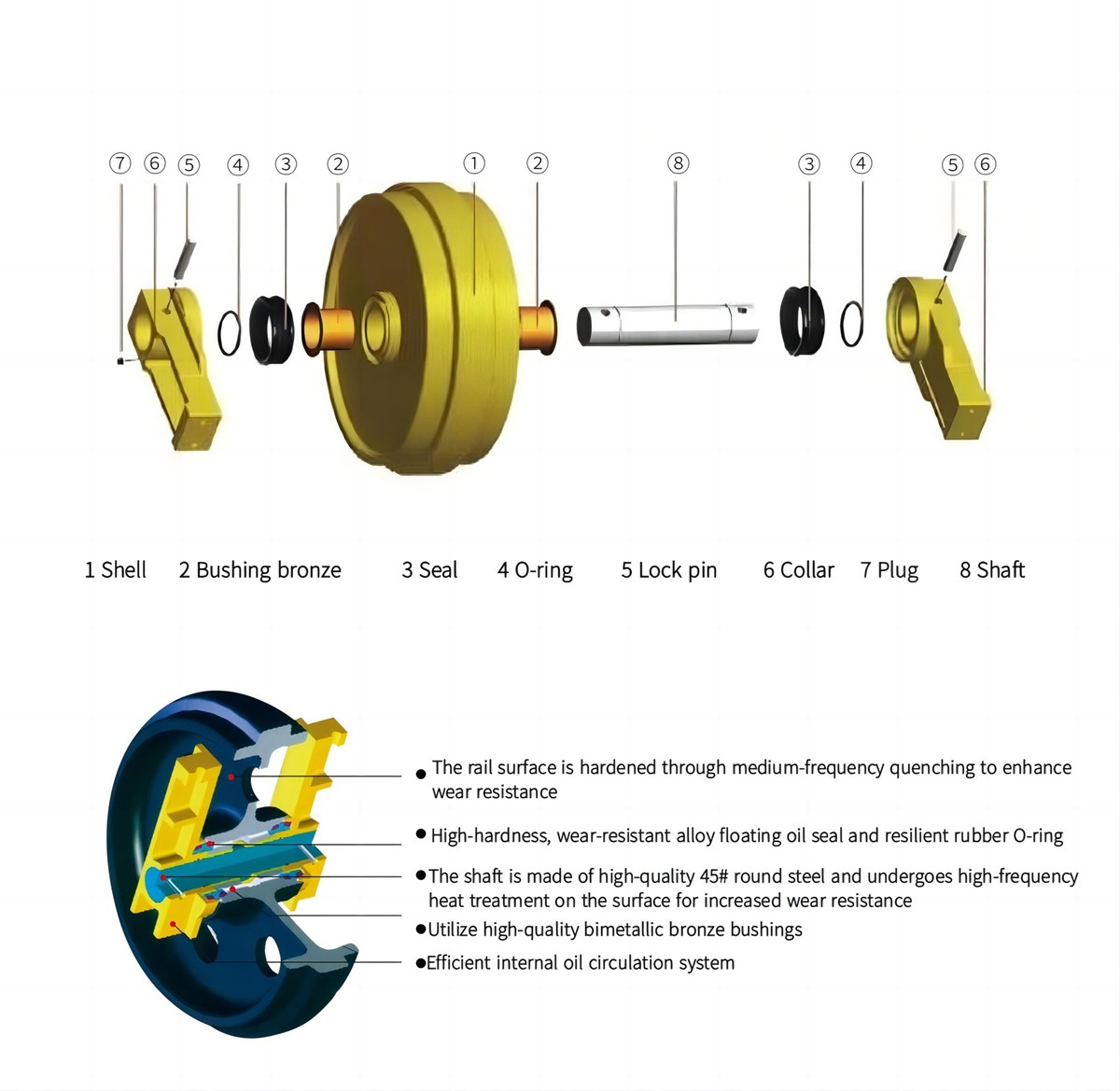

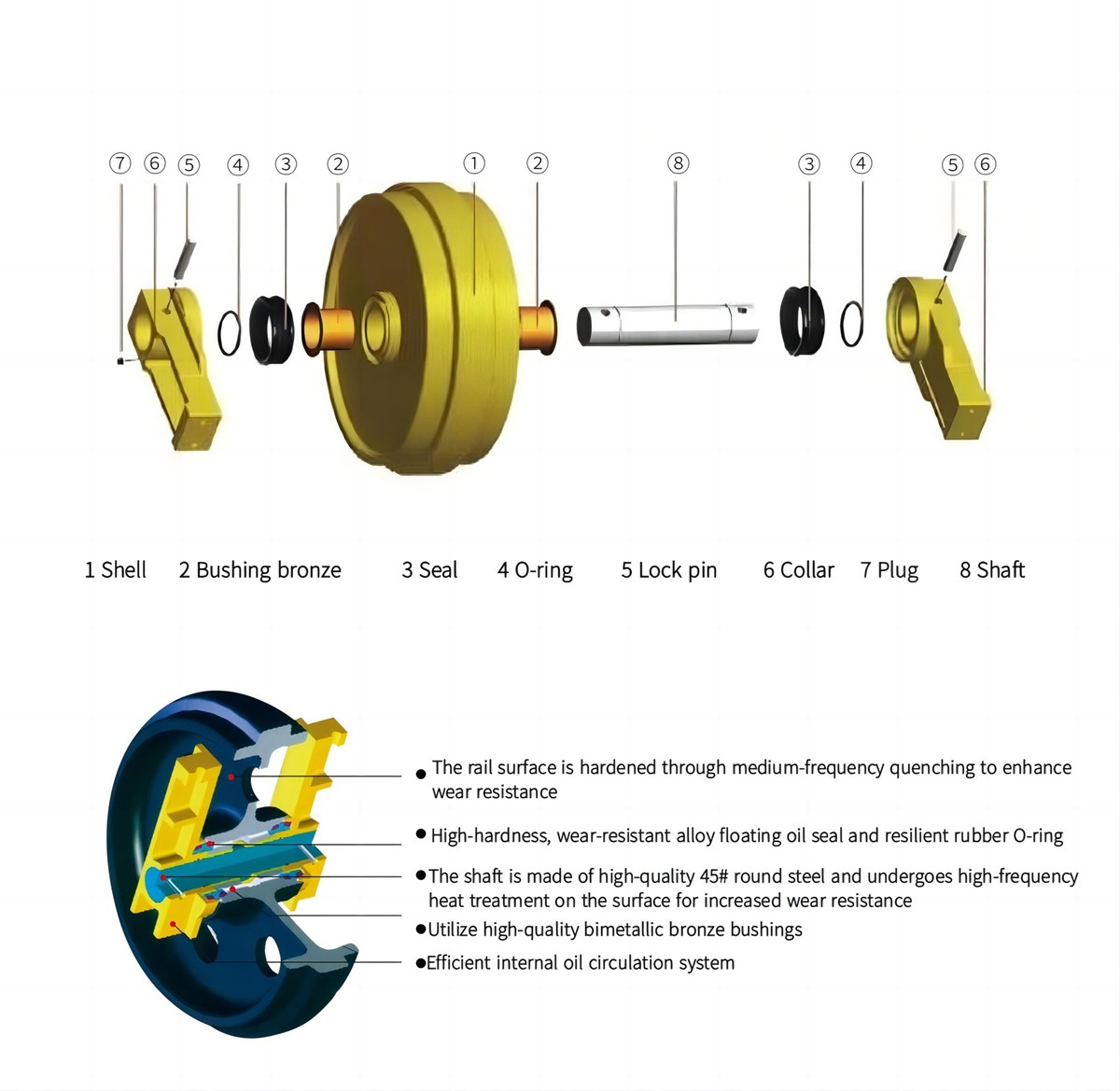

- Product Advantages:

1. Our Idlerozer is crafted using premium quality materials. The of high-grade alloys ensures exceptional strength and durability, allowing the machine to withstand the most challenging environments with ease.

2. Rigorous Heat Treatment Process: Each component of our Idler Bulldozer undergoes a meticulous heat treatment process. This intensive treatment enhances the surface hardness and toughness, guaranteeing reliable performance even in the most demanding working conditions.

3. Exceptional Hardness and Toughness: With its impeccable heat treatment, our Idler Bulldozer achieves an outstanding combination of surface hardness and toughness. This unique balance ensures optimum wear resistance against abrasion, extending the lifespan of the product and minimizing maintenance costs.

4. Stringent Quality Inspection: Every single part of our Idler Bulldozer undergoes rigorous quality inspections. Our experienced technicians meticulously examine each component to ensure they meet the highest industry standards, guaranteeing the reliability and overall performance of the machine.

5. Unparalleled Durability: The meticulous attention to detail in the construction of our Idler Bulldozer results in a product that offers exceptional durability. Designed to withstand heavy usage and harsh working conditions, this bulldozer provides superior performance over an extended period.

- Why Choose Us

1. Extensive Production Experience:

With years of experience in the industry, we have become experts in the production of Idler Bulldozers. Our team's wealth of knowledge and skills ensures that every product is manufactured to the highest standards of quality and reliability.

2. Strong Product Development Capability:

We pride ourselves on our ability to continually innovate and develop new technologies for Idler Bulldozer production. Our dedicated research and development team works tirelessly to improve product performance, efficiency, and durability.

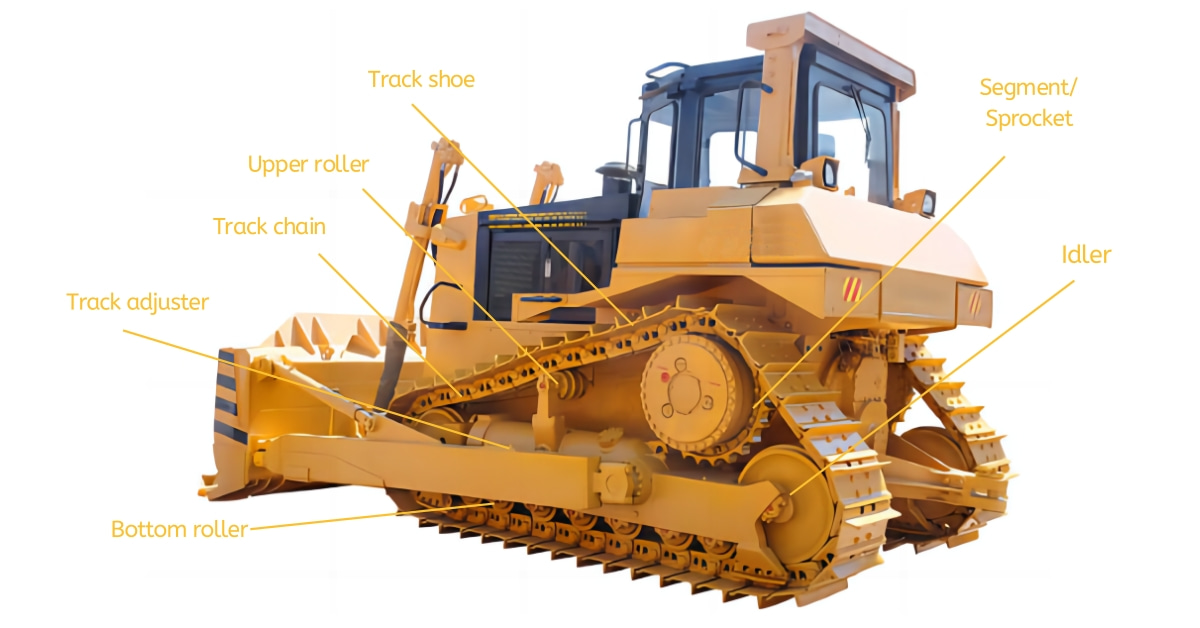

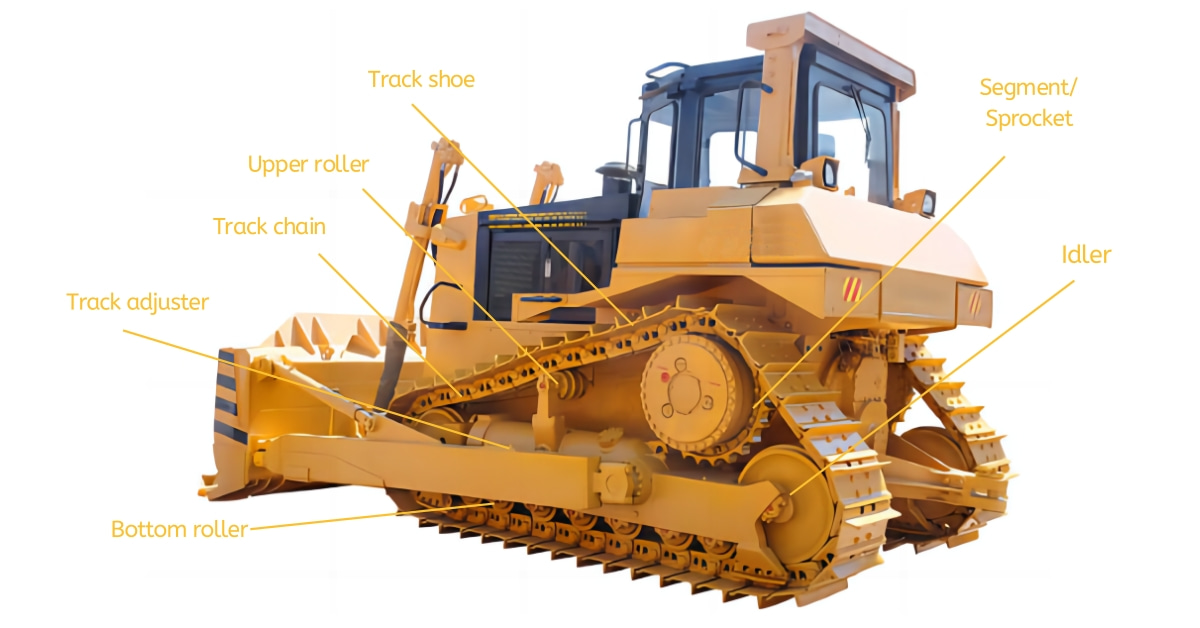

3. Broad Range of Bulldozer and Excavator Undercarriage Parts:

Our product line boasts a diverse range of undercarriage parts for bulldozers and excavators. From idlers to track shoes, rollers to sprockets, we provide comprehensive solutions to meet all your undercarriage needs. Choose from our extensive selection of high-quality parts designed to fit a variety of machine models.

4. Emphasis on Product Quality:

Quality is our top priority. We strictly adhere to international quality standards throughout every stage of production. From sourcing the finest materials to implementing rigorous quality control measures, we are committed to delivering superior products that exceed customer expectations.

5. Customer-Centric Approach:

We believe in building lasting partnerships with our customers. Our dedicated customer service team is always available to provide prompt assistance and support. We listen to your needs and strive to meet your requirements, ensuring your satisfaction with our products and services.

6. Employee Welfare and Care:

At our company, we understand the importance of our employees. We prioritize their well-being and provide a safe and inspiring working environment. We foster a culture of continuous learning and professional growth, encouraging our team members to reach their full potential.

- Bulldozer Idler Part Number For Inference

Model OEM Part No.

D8N/D8R 9W9989 Front Idler

D9N/D9R 7T2769 Dozer Idler

D10N/D10R 7T0962 Bulldozer ldler

D20/D21 103-30-00120 Idler For Dozer

D30/D31 113-30-00102 ldler For Bulldozer

D50 131-30-00285 Idler Fit For Komatsu Dozer

D65-8 144-30-00038 Idler

D65-12 14X-30-00112 ldler

D85-18 154-30-00293 Idler

D85-21 154-30-00770 Idler

D155A-1 175-30-00575 Idler

D355A-3 195-30-00283 Idler

D3C 9N4173 Idler Fit For CAT Dozer

D4D/D4E 1M8867 Idler Fit For CAT Bulldozer

D4H 190-1534 Idler

D4H 190-1551 Idler

D5 CR3190 Idler

D5H 161-7549 Idler

D6C/D6D 7T4562 ldler

D6H/D6R 2024296 Idler

D6H/D6R 2024304 Idler

D7F/D7G 7T4509 Idler

D8K CR4096 Idler

D8N/D8R 9W9987 Idler

Network Supported

Network Supported