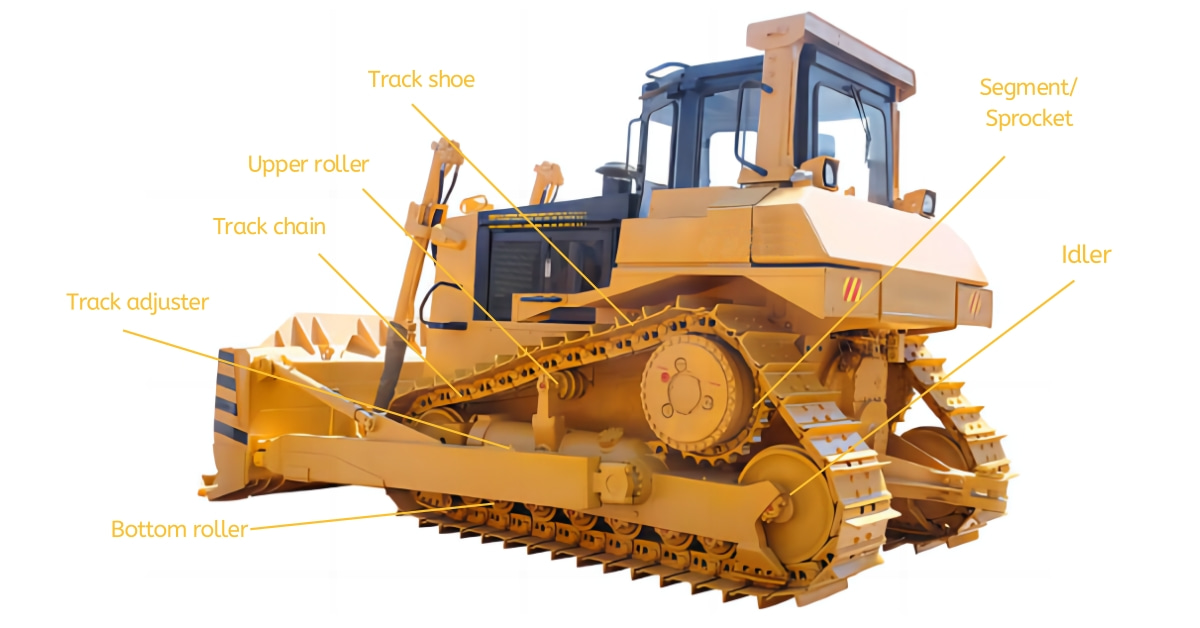

Dozer Undercarriage Parts

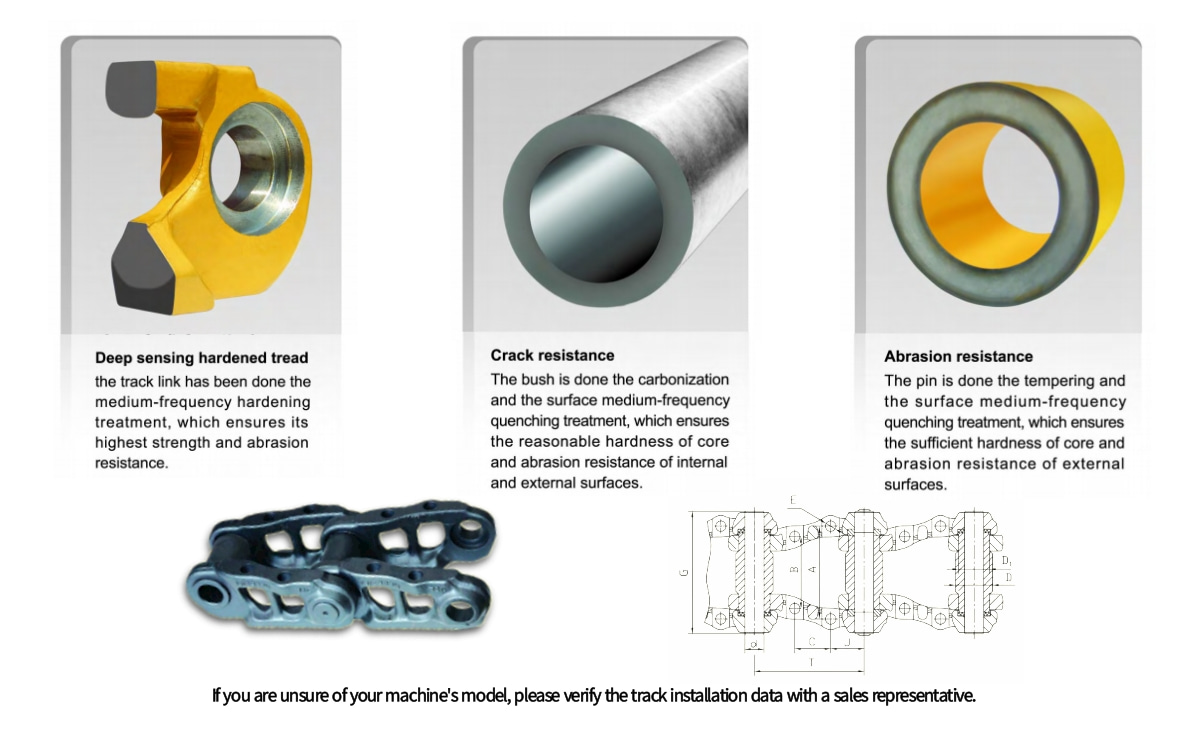

Enhance your machinery performance and durability with high-quality Dozer Undercarriage Track Chains for D9N, D9T, and D9R models. Impeccably crafted with superior hardness and remarkable toughness, these tracks offer exceptional wear resistance for extended usage. With excellent lubrication capabilities, our track chains ensure smooth operation, guaranteeing long-lasting performance.

| D9N track chains part number | CR4653 CR5866A CR6125 |

| Material | 40Cr、35MnB |

| Finish | Smooth |

| Colors | Black or yellow |

| Processing | Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness | HRC52-58,deepth:8mm-12mm |

| Delivery Time | Within 30 days after payments |

| OEM/ODM Service | Available |

| MOQ | 1 Set |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported