Dozer Undercarriage Parts

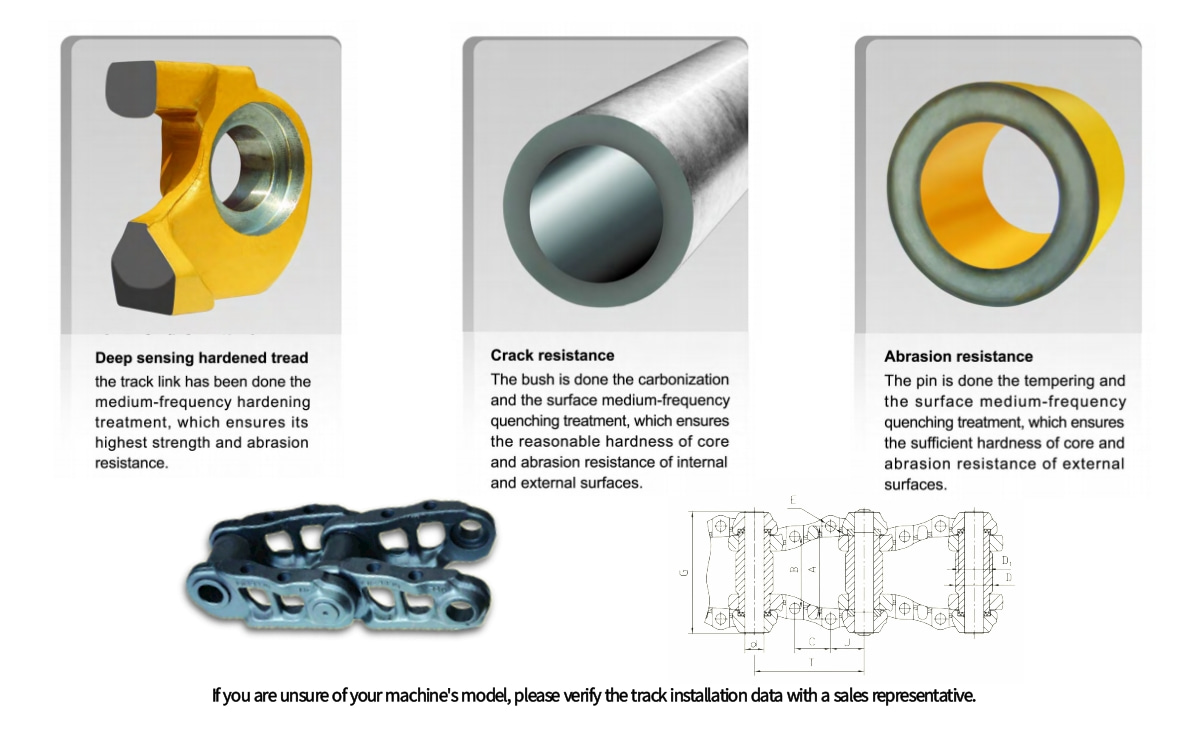

Dozer Sealed Track Link is made from high-grade alloy steel, ensuring exceptional strength and hardness. Advanced heat treatment processes provide superior wear resistance and durability. The integrated sealing system maintains excellent lubrication, reducing maintenance needs. Designed to withstand diverse working conditions, it offers reliable, long-lasting performance. Ideal for heavy-duty applications, this track link guarantees consistent efficiency and durability.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported