Dozer Undercarriage Parts

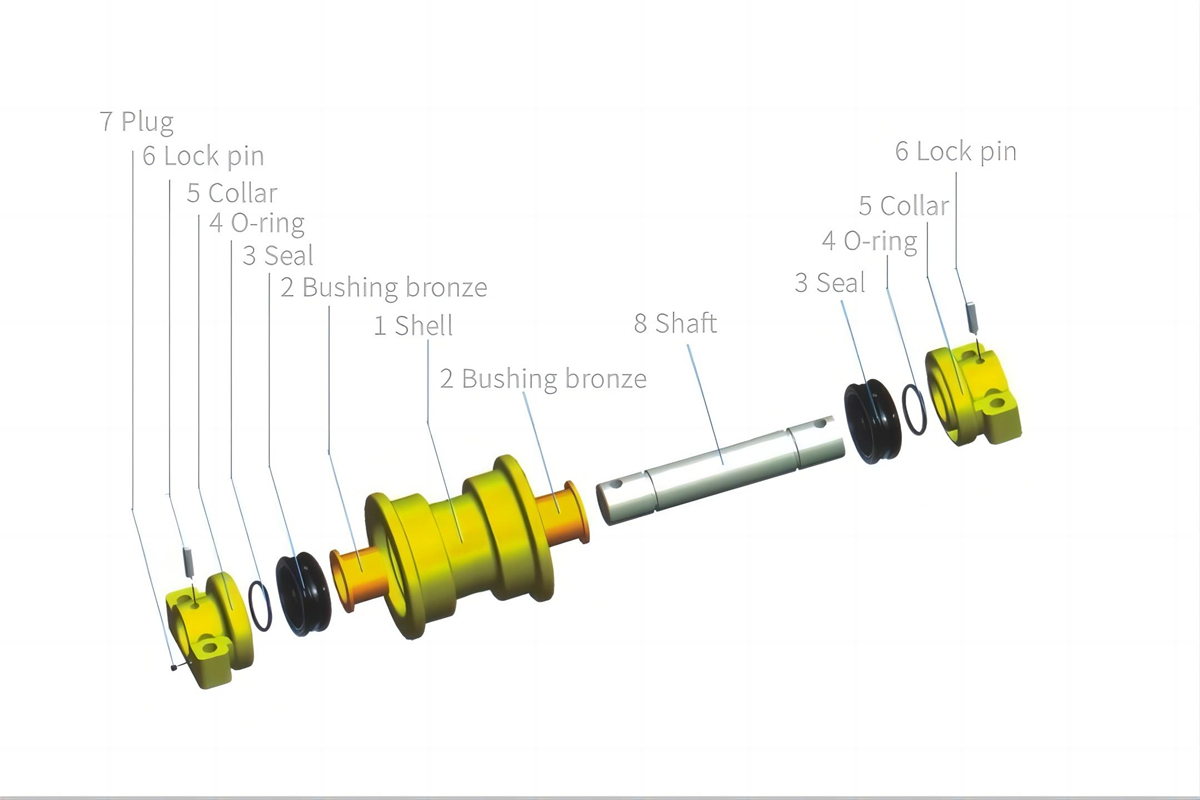

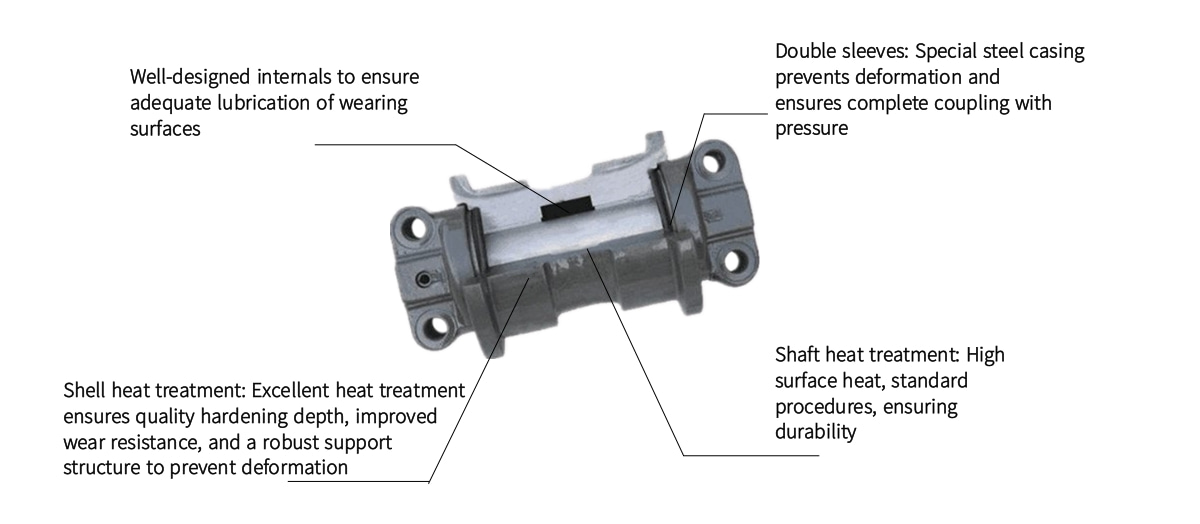

Designed for durability and reliability, the Dozer Lower Roller Single Flange D50 is built to withstand the toughest conditions. Crafted with exceptional wear resistance, this product guarantees long-lasting performance, ensuring uninterrupted operations. Its versatility allows seamless adaptability to diverse work environments, making it the ideal choice for any industrial setting.

| Material | 50Mn/40SiMnTi |

| Finish | Smooth |

| Processing | Forging, Casting, Machining, Heat treatment Quenching |

| Colors | Black or yellow |

| Surface Hardness | HRC50-56,deepth:4mm-10mm |

| Warranty time | 2000 hour/ 6 months |

| MOQ | 2 piece |

| Delivery Time | Within 10 days after payments |

| OEM/ODM Service | Available |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported