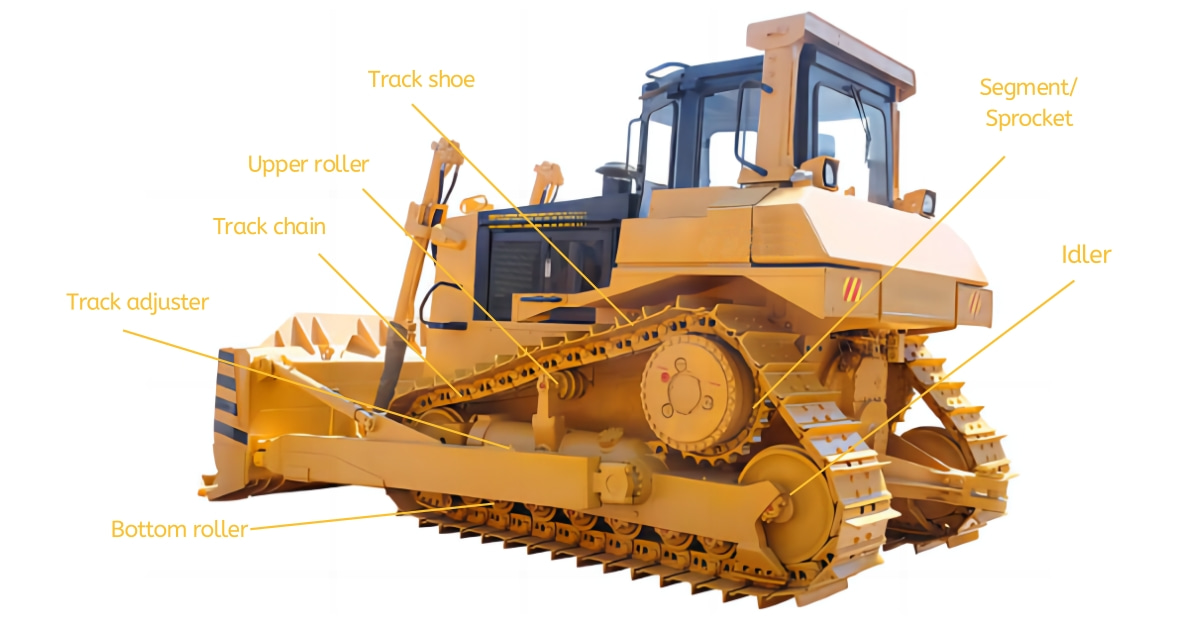

Dozer Undercarriage Parts

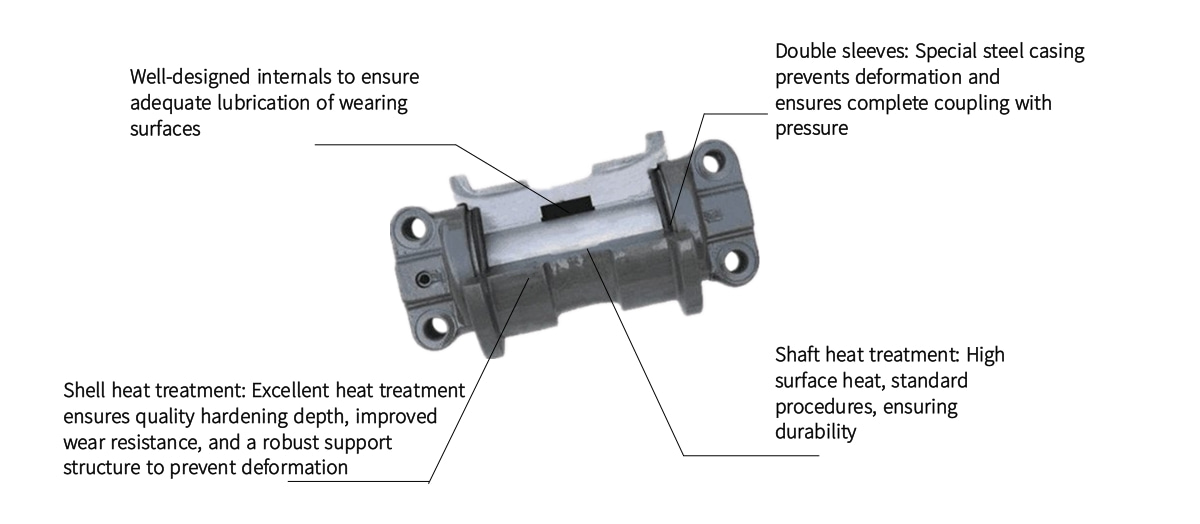

Crafted from premium quality materials, the Dozer Bottom Roller Single Flange D8N CR4528 is a durable and long-lasting product with exceptional wear resistance. Its reliable performance is a testament to its outstanding quality and stability. This meticulously designed roller excels in providing superior traction and stability, making it the ideal choice for demanding industries.

| D8N bottom roller part number | CR4528 |

| Material | 50Mn/40SiMnTi |

| Finish | Smooth |

| Processing | Forging, Casting, Machining, Heat treatment Quenching |

| Colors | Black or yellow |

| Surface Hardness | HRC50-56,deepth:4mm-10mm |

| Warranty time | 2000 hour/ 6 months |

| MOQ | 2 piece |

| Delivery Time | Within 10 days after payments |

| OEM/ODM Service | Available |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported