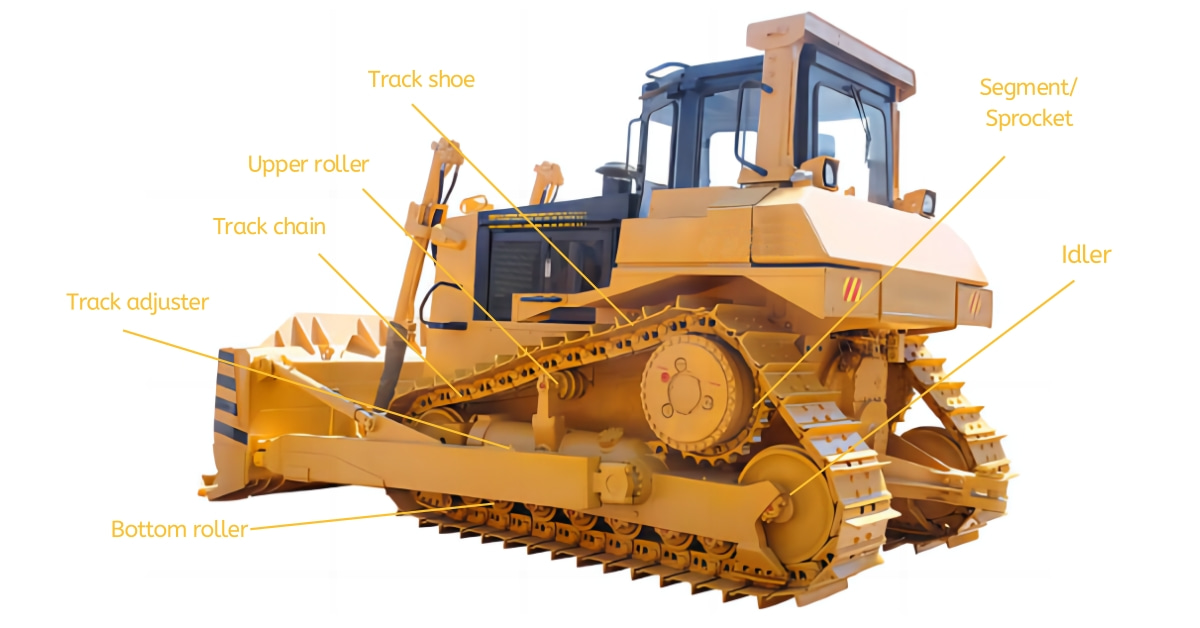

Dozer Undercarriage Parts

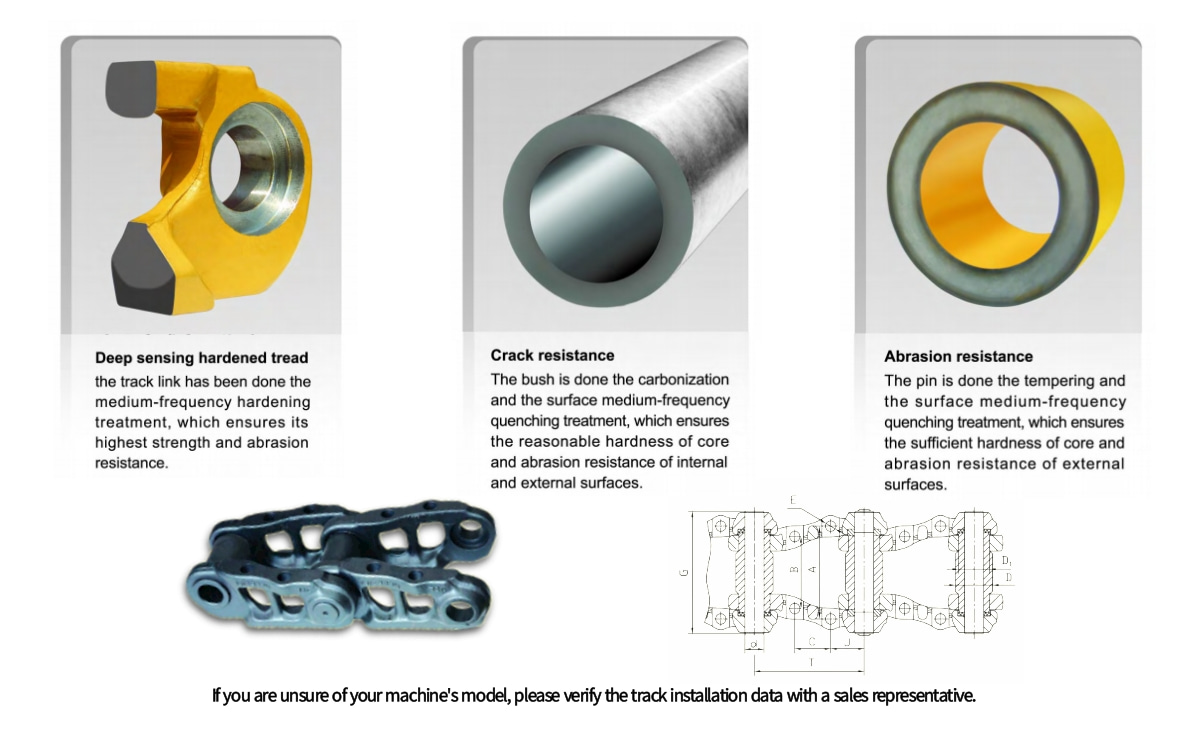

The D7G CR4268/38 Bulldozer Undercarriage Track Chains, designed with precision engineering and exceptional durability, are essential components for optimizing the performance of your heavy-duty machinery. Crafted using the finest quality materials, these track chains ensure optimal traction and stability, allowing your bulldozer to conquer any terrain with ease. Unlock the true potential of your machinery and improve productivity with the unmatched reliability of the D7G CR4268/38 Bulldozer Undercarriage Track Chains.

| Material | 40Cr、35MnB |

| Finish | Smooth |

| Colors | Black or yellow |

| Processing | Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness | HRC52-58,deepth:8mm-12mm |

| Delivery Time | Within 30 days after payments |

| OEM/ODM Service | Available |

| MOQ | 1 Set |

MODEL & PART NOS BERCO NOS LINKS PITCH

D3C 6Y1713 CR4749/39 39L 155

D4D 7K2372 CR2567/40 40L 171

D4E 1V7072 CR3628/36 36L 171

D5 5S0816 CR2823/39,CR5035/ 39L 175

D5B 3P3885 CR3520/39 39L 175

D5B 953 7T4637 CR4264/4040 40L 175

D4H 6Y5407 CR5192/39 39L 171

D5H 6Y5412 CR5202/37 37L 190

D6D 963 9W8843 CR4267/36 36L 203

D6C 225 229 6P6131 CR3176/36,CR5059/ 36L 203

D6H 6Y5417 CR4810A/40 CR6587 40L 203

D6R 6I9670 CR5534/40 40L 203

D7 977K 1S6943 CR1769/41 41L 203

D7G 235B 8S2607 CR2567/38,CR5061 38L 216

973 9W9167 CR4700/40 40L 216

D7H 6Y1141 CR5069/40 40L 216

D8K 2P9492 CR3149/41 41L 228

D8R 8E4518 CR4525/44 44L 216

D9H 8S1731 CR2672/39 39L 260

D10R 2389851 CR6075/44 44L 260

D20-6,7 102-32-00032 KM906/37 37L 135

D31P-18,20 11G-32-00025 KM727/41 41L 154

D61X-12 13G-32-00020 KM2868/46 46L 190

D65-8 141-32-00045 KM953/39 39L 203

D65 144-32-00054 KM951/37 37L 203

D65 141-32-00065 KM951/39 39L 203

D65PX-15 14Y-32-00110 KM3467/45 45L 203

D85SS-2 14U-32-00010 KM2094/42 42L 203

D85-21 154-32-00400 KM1103/39 39L 216

D85EX-15 154-32-00620 KM3904/41 41L 216

D155 175-32-00103 KM325/41 41L 228

D275A-5 17M-32-00400 KM3593/39 39L 260

D355A-5 195-32-00105 KM596/39 39L 260

D375A-5 195-32-00591 KM3599A/40 40L 280

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported