Dozer Undercarriage Parts

Experience unmatched performance and durability with our D6K Bulldozer Track Roller Double Flange. Crafted to perfection, this high-quality roller is designed to provide exceptional traction and smooth operation, ensuring optimal performance in even the toughest terrains.

| Material | 40SiMnTi/50Mn/35MnB/40MnB/40Mn2 |

| Finish | Smooth |

| Processing | Forging, Casting, Machining, Heat treatment |

| Surface Hardness | HRC48-54,deepth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty Time | 2000 hour |

| Delivery Time | Within 15days after payments. |

| MOQ | 2set |

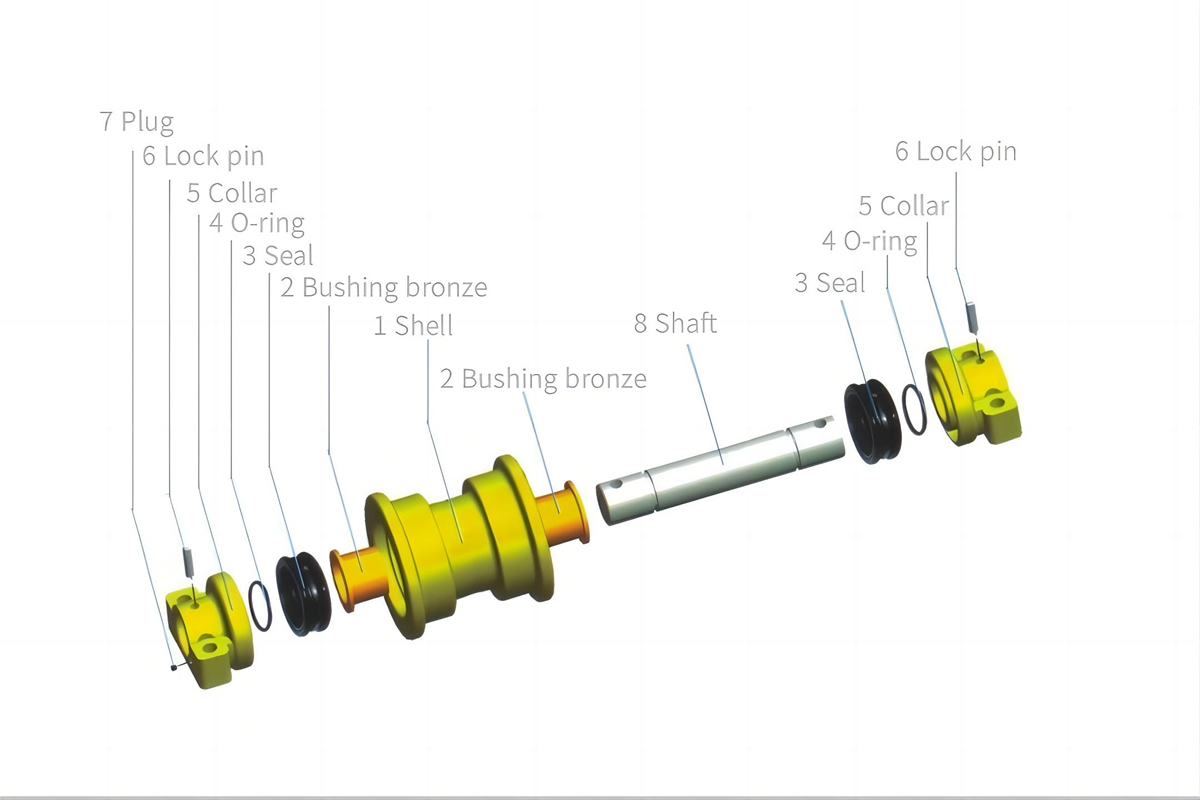

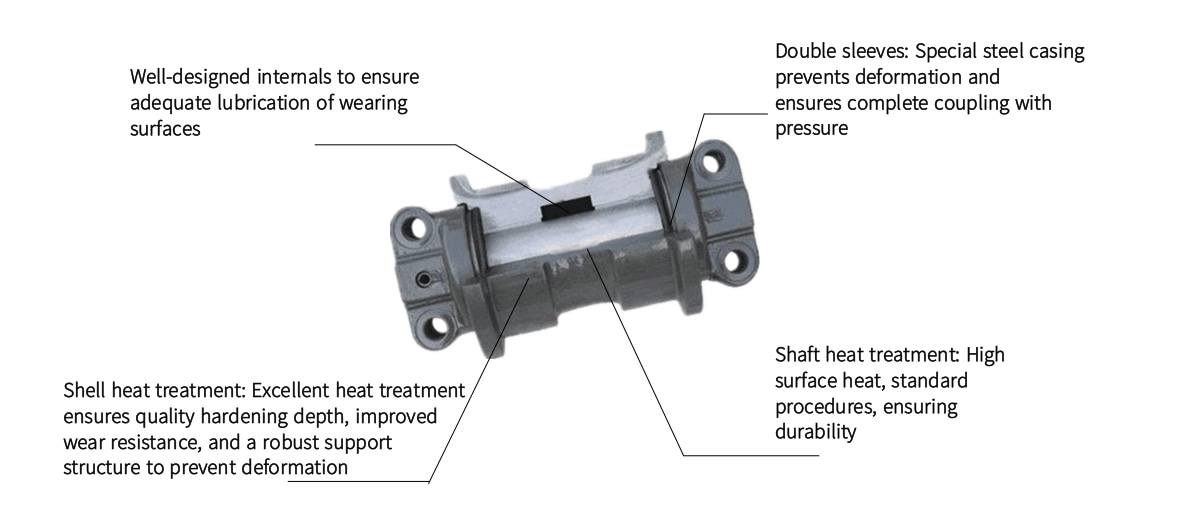

1. Superior Material: The D6K Bulldozer Track Roller Double Flange is manufactured using high-quality materials. The roller is fabricated from a robust and durable alloy steel, ensuring exceptional strength and longevity.

2. Rigorous Heat Treatment: Our rollers undergo a meticulous heat treatment process, guaranteeing a remarkable surface hardness of HRC48-53. This meticulous treatment enhances the wear resistance and overall performance of the roller, prolonging its service life.

3. Stringent Quality Inspection: Each and every component of the D6K Bulldozer Track Roller Double Flange is subjected to strict quality inspections. Our dedicated team of experts meticulously scrutinizes every detail to ensure that the product meets the highest standards of quality and reliability.

4. Exceptional Reliability: With a focus on precision engineering and quality control, our D6K Bulldozer Track Roller Double Flange offers exceptional reliability. Every roller is designed to withstand heavy loads, extreme operating conditions, and extensive usage without compromising performance.

5. High Cost-effectiveness: Our D6K Bulldozer Track Roller Double Flange provides outstanding value for your investment. You can rely on its exceptional durability and performance, which eliminates the need for frequent replacements. This, in turn, helps to reduce maintenance costs and downtime significantly.

| Model | OEM Part No. |

| D9N/D9R | 7T1253 Dozer Track Roller |

| D10N/D10R | 6Y0889 Bulldozer Track Roller |

| D31-16 | 113-30-00282 Track Roller For Dozer |

| D41-6 | 124-30-52602 Track Roller Fit For Komatsu |

| D50-15/D60-3 | 131-30-00322 Track Roller |

| D60-6 | 141-30-00578 Track Roller |

| D65-12 | 14X-30-00081 Track Roller |

| D80-12 | 154-30-00505 Track Roller |

| D80-18 | 155-30-00126 Track Roller |

| D85E-18 | 155-30-00117 Track Roller |

| D150A-1/D155A-1 | 175-30-00486 Track Roller |

| D155AX-3 | 17A-30-00080 Track Roller |

| D3B/D3C | 6S3607/3T4352 Dozer Bottom Roller |

| D4C/D4D |

7K8096/7K8084 Track Roller Fit For CAT dozer |

| D5 | 9S9539 Bottom Roller For Sale |

| D5H | 9P1363 Track Roller |

| D6C | 9S9403 Track Roller |

| D6D | 7G0423/9G8034 Track Roller |

| D6R | 120-5746 Track Roller |

| D6H | 7T4107 Track Roller |

| D7G | 9S0316/4S9051 Track Roller |

| D8N | 9W8706/7G9193 Track Roller |

| D8K | 6P4897/7S9041 Track Roller |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported