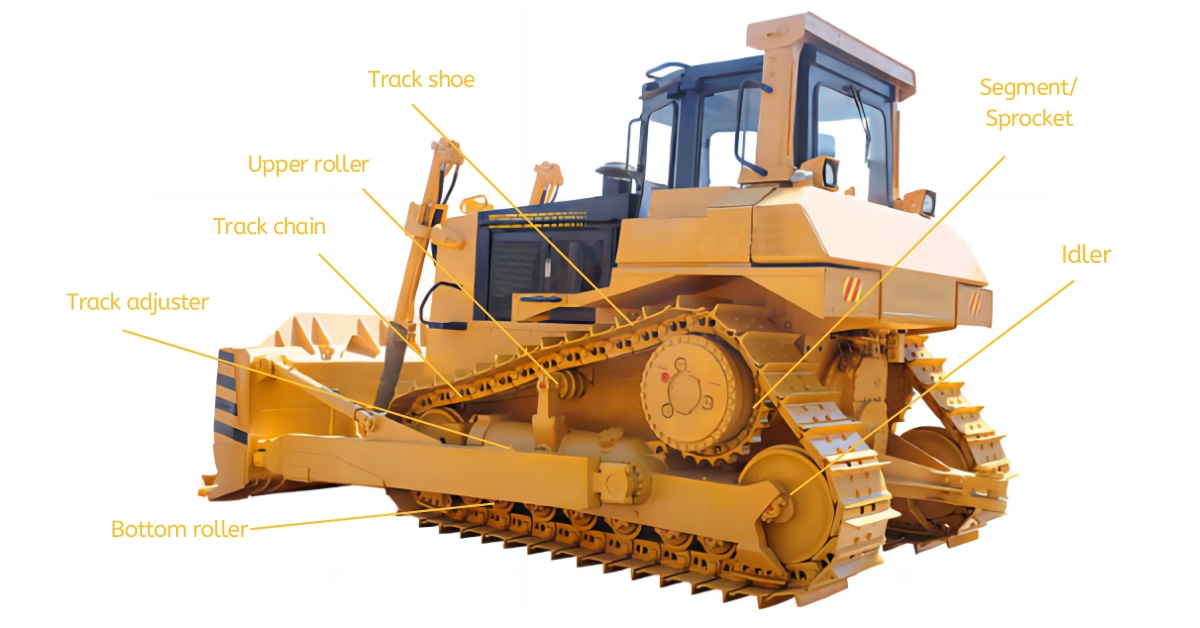

Dozer Undercarriage Parts

Enhance your construction projects with the premium quality D375 Dozer Front Idler Assembly 195-30-01030 Fit For Komatsu. Engineered with precision and durability in mind, this essential component ensures smooth operation and maximum performance. Upgrade your machinery today and experience the difference in efficiency and reliability.

| Material | 50Mn/40MnB/40simnti |

| Finish | Smooth |

| Colors | Black or yellow |

| Technique | Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness | HRC52-60,deepth:4mm-10mm |

| Warranty time | 2000 hour |

| MOQ | 2 piece |

| Delivery Time | Within 7-30 days after payments |

| HS Code | 8431499900 |

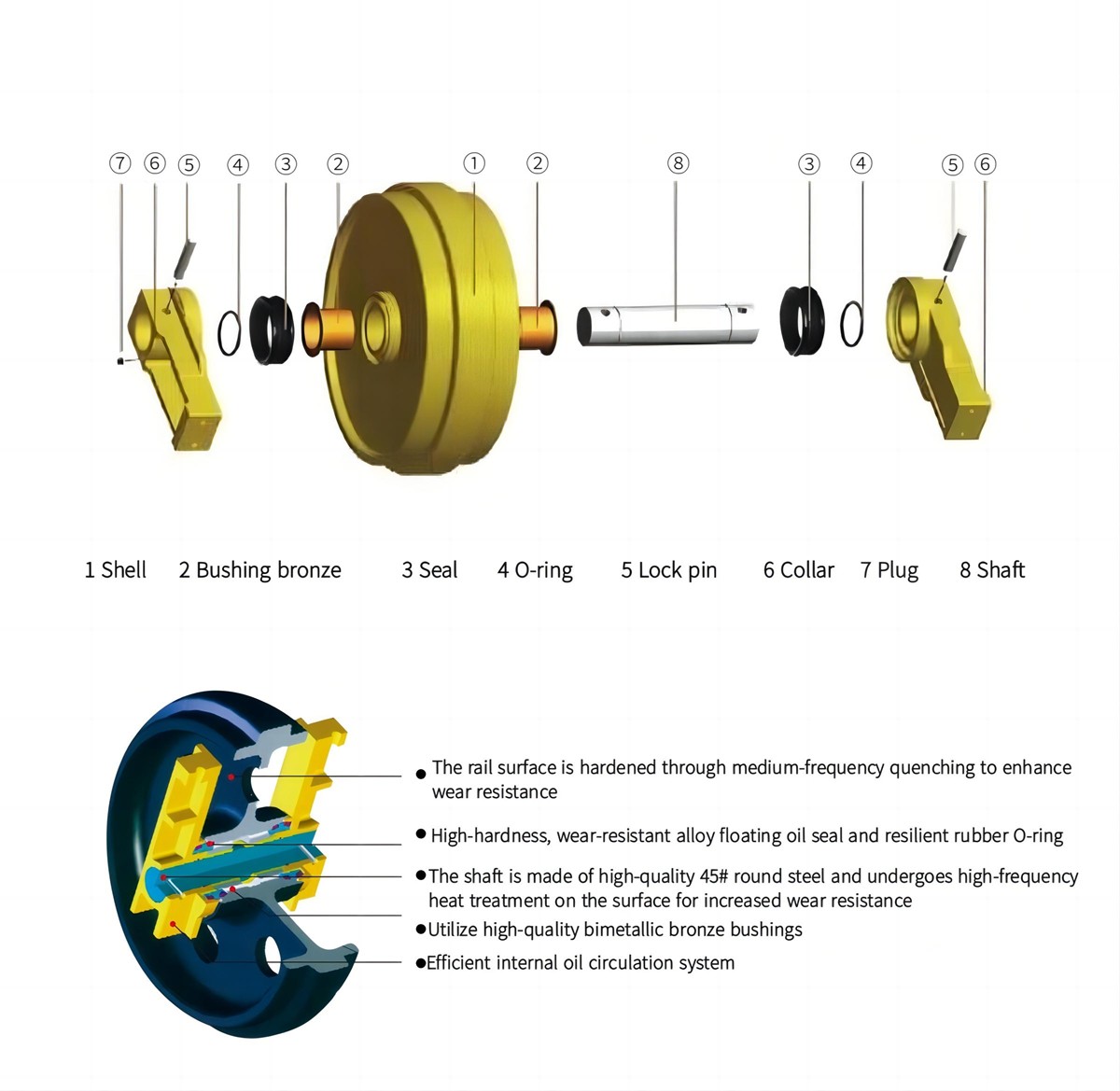

1. Superior Quality Materials: Our D375 Dozer Front Idler Assembly is crafted from high-quality materials that guarantee exceptional performance and longevity. The carefully selected materials ensure durability and reliability, allowing for extended usage in various working conditions.

2. Rigorous Heat Treatment Process: Each component of the Front Idler Assembly undergoes a stringent heat treatment process to enhance its hardness and toughness. This meticulous procedure ensures that the idler assembly is capable of withstanding heavy loads, harsh terrains, and extreme working environments.

3. Excellent Sealing and Lubrication Properties: The D375 Dozer Front Idler Assembly is designed with exceptional sealing and lubrication capabilities. Its specialized sealing system effectively prevents dust, dirt, and moisture from entering the assembly, thus minimizing wear and tear. Furthermore, the idler assembly's advanced lubrication mechanism ensures smooth rotation and reduces friction, resulting in improved overall machinery performance.

4. Reliable and Stable Quality: We take pride in delivering products with consistent and reliable quality. Our D375 Dozer Front Idler Assembly undergoes rigorous quality control measures at every stage of manufacturing, ensuring that each unit meets or exceeds industry standards. With our product, you can have confidence in its stability and reliability, allowing for seamless and uninterrupted operation.

5. Long-lasting Durability: The D375 Dozer Front Idler Assembly is engineered to withstand continuous usage and demanding working conditions. Its robust construction and superior materials guarantee its long-lasting durability, making it an ideal choice for heavy-duty applications. You can rely on this idler assembly to provide superior performance and extend the lifespan of your equipment, resulting in cost savings and increased productivity.

1. Extensive Production Experience:

With years of experience in the industry we have honed skills and perfected our techniques, ensuring top-notch quality products every time. Our team of experts understands the intricacies of the manufacturing process, guaranteeing outstanding results.

2. Stringent Production Management Process:

At our facility, we strictly adhere to a well-defined production management process. From material sourcing to the final assembly, every step is meticulously planned and executed to ensure precision and quality. Our dedication to excellence is reflected in the flawless performance of our D375 Dozer Front Idler Assembly.

3. Rigorous Quality Inspection:

We have implemented a rigorous quality inspection system to ensure that every product meets our high standards. Each D375 Dozer Front Idler Assembly undergoes thorough testing and scrutiny to verify its durability, reliability, and compatibility with Komatsu equipment. This unwavering commitment to quality guarantees the longevity and superior performance of our products.

4. Emphasis on Product Research and Development:

We understand the importance of innovation in today's rapidly evolving market. Therefore, we invest substantial resources in product research and development. Our team of engineers and technicians constantly strive to enhance the performance and efficiency of our undercarriage parts, ensuring it remains at the forefront of technological advancements.

5. Wide Range of Bulldozer Undercarriage Parts:

As a trusted supplier in the industry, we offer a comprehensive product line of bulldozer undercarriage parts. Our D375 Dozer Front Idler Assembly is just one example of the high-quality components we provide. Whether you need track rollers, sprockets, or track chains, our extensive range ensures you can find the perfect fit for your Komatsu bulldozer.

6. Focus on Customer Service:

Customer satisfaction is our top priority. We go above and beyond to ensure that our clients receive the utmost level of service. Our dedicated support team is always ready to assist with any inquiries, and our prompt delivery ensures that your business operations continue uninterrupted.

7. Team of Professionals:

Behind our success is a team of highly skilled professionals who bring their expertise and passion to the table. From our production technicians to our customer service representatives, each member of our team is committed to delivering excellence. You can trust in our knowledge and proficiency to provide you with the best D375 Dozer Front Idler Assembly for your Komatsu equipment.

Model OEM Part No.

D8N/D8R 9W9989 Front Idler

D9N/D9R 7T2769 Dozer Idler

D10N/D10R 7T0962 Bulldozer ldler

D20/D21 103-30-00120 Idler For Dozer

D30/D31 113-30-00102 ldler For Bulldozer

D50 131-30-00285 Idler Fit For Komatsu Dozer

D65-8 144-30-00038 Idler

D65-12 14X-30-00112 ldler

D85-18 154-30-00293 Idler

D85-21 154-30-00770 Idler

D155A-1 175-30-00575 Idler

D355A-3 195-30-00283 Idler

D3C 9N4173 Idler Fit For CAT Dozer

D4D/D4E 1M8867 Idler Fit For CAT Bulldozer

D4H 190-1534 Idler

D4H 190-1551 Idler

D5 CR3190 Idler

D5H 161-7549 Idler

D6C/D6D 7T4562 ldler

D6H/D6R 2024296 Idler

D6H/D6R 2024304 Idler

D7F/D7G 7T4509 Idler

D8K CR4096 Idler

D8N/D8R 9W9987 Idler

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported