Dozer Undercarriage Parts

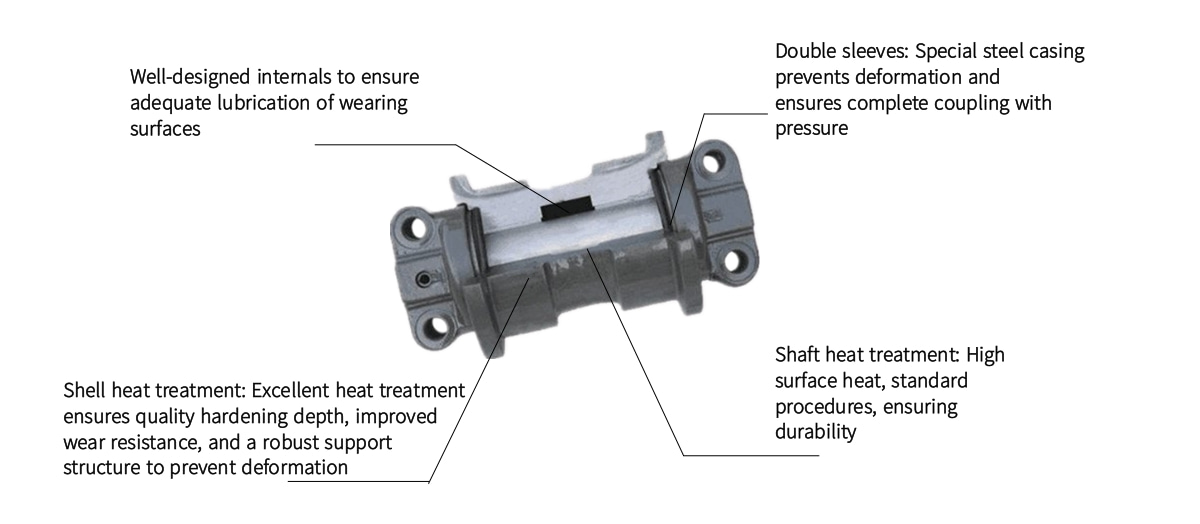

Crafted with precision and durability, our Track Roller Bottom Roller is exclusively designed for the renowned D10N, D10T, and D10R Dozer models. Engineered to deliver unparalleled performance, this reliable component ensures smooth and efficient operation in even the most challenging terrains. Invest in excellence and empower your machinery with our Track Roller Bottom Roller, guaranteeing extended lifespan and unmatched productivity.

| Material | 50Mn/40SiMnTi |

| Finish | Smooth |

| Processing | Forging, Casting, Machining, Heat treatment Quenching |

| Colors | Black or yellow |

| Surface Hardness | HRC50-56,deepth:4mm-10mm |

| Warranty time | 2000 hour/ 6 months |

| MOQ | 2 piece |

| Delivery Time | Within 30 days after payments |

| OEM/ODM Service | Available |

1. Rich Production Experience:

With years of experience in the industry, we have mastered the art of manufacturing D10N, D10T, and D10R dozer track roller bottom rollers. Our extensive knowledge and expertise enable us to meet the diverse needs of our customers effectively.

2. Continuous Process and Technological Improvements:

We believe in staying at the forefront of innovation. Therefore, we consistently strive to improve our production processes and adopt the latest technologies. By doing so, we ensure that our products are manufactured with the highest level of precision and efficiency, surpassing industry standards.

3. Emphasis on Product Quality:

At our company, product quality is our topmost priority. We adhere to strict quality control measures throughout the manufacturing process. Each and every dozer track roller bottom roller undergoes rigorous inspection and testing to ensure that it meets the most stringent quality requirements. This commitment to excellence ensures that our customers receive products of unmatched durability and performance.

4. Focus on New Product Development:

We understand the importance of offering cutting-edge solutions to our customers. That's why we continuously invest in research and development to bring innovative products to the market. Our dedication to new product development ensures that our customers have access to the latest advancements in track roller technology, providing them with a competitive edge.

5. Customer-centric Approach:

Our commitment to customer satisfaction is unwavering. We prioritize the needs of our customers and strive to provide exceptional service at every touchpoint. From prompt and reliable communication to on-time delivery, we ensure a seamless experience for our customers. Our dedicated support team is always available to address any inquiries or concerns, fostering long-term partnerships based on trust and dependability.

| Model | OEM Part No. |

| D9N/D9R | 7T1253 Dozer Track Roller |

| D10N/D10R | 6Y0889 Bulldozer Track Roller |

| D31-16 | 113-30-00282 Track Roller For Dozer |

| D41-6 | 124-30-52602 Track Roller Fit For Komatsu |

| D50-15/D60-3 | 131-30-00322 Bottom Roller For Dozer |

| D60-6 | 141-30-00578 Track Roller |

| D65-12 | 14X-30-00081 Track Roller |

| D80-12 | 154-30-00505 Track Roller |

| D80-18 | 155-30-00126 Track Roller |

| D85E-18 | 155-30-00117 Track Roller |

| D150A-1/D155A-1 | 175-30-00486 Track Roller |

| D155AX-3 | 17A-30-00080 Track Roller |

| D3B/D3C | 6S3607/3T4352 Dozer Bottom Roller |

| D4C/D4D |

7K8096/7K8084 Track Roller Fit For CAT dozer |

| D5 | 9S9539 Bottom Roller For Sale |

| D5H | 9P1363 Track Roller |

| D6C | 9S9403 Track Roller |

| D6D | 7G0423/9G8034 Track Roller |

| D6R | 120-5746 Track Roller |

| D6H | 7T4107 Track Roller |

| D7G | 9S0316/4S9051 Track Roller |

| D8N | 9W8706/7G9193 Track Roller |

| D8K | 6P4897/7S9041 Track Roller For CAT |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported