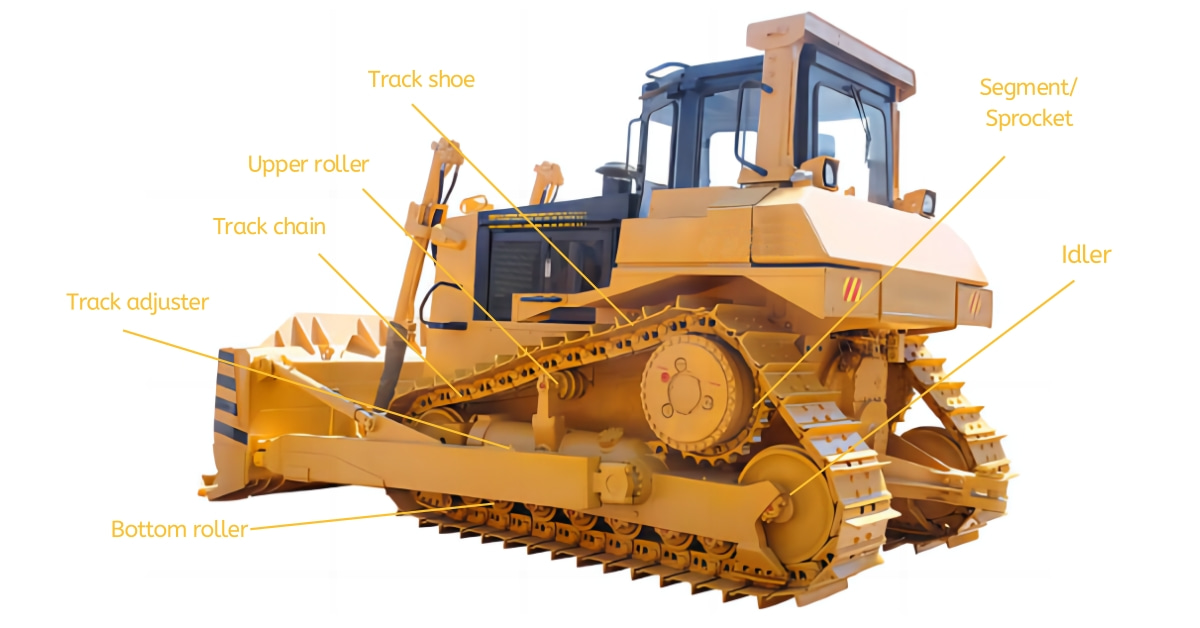

Dozer Undercarriage Parts

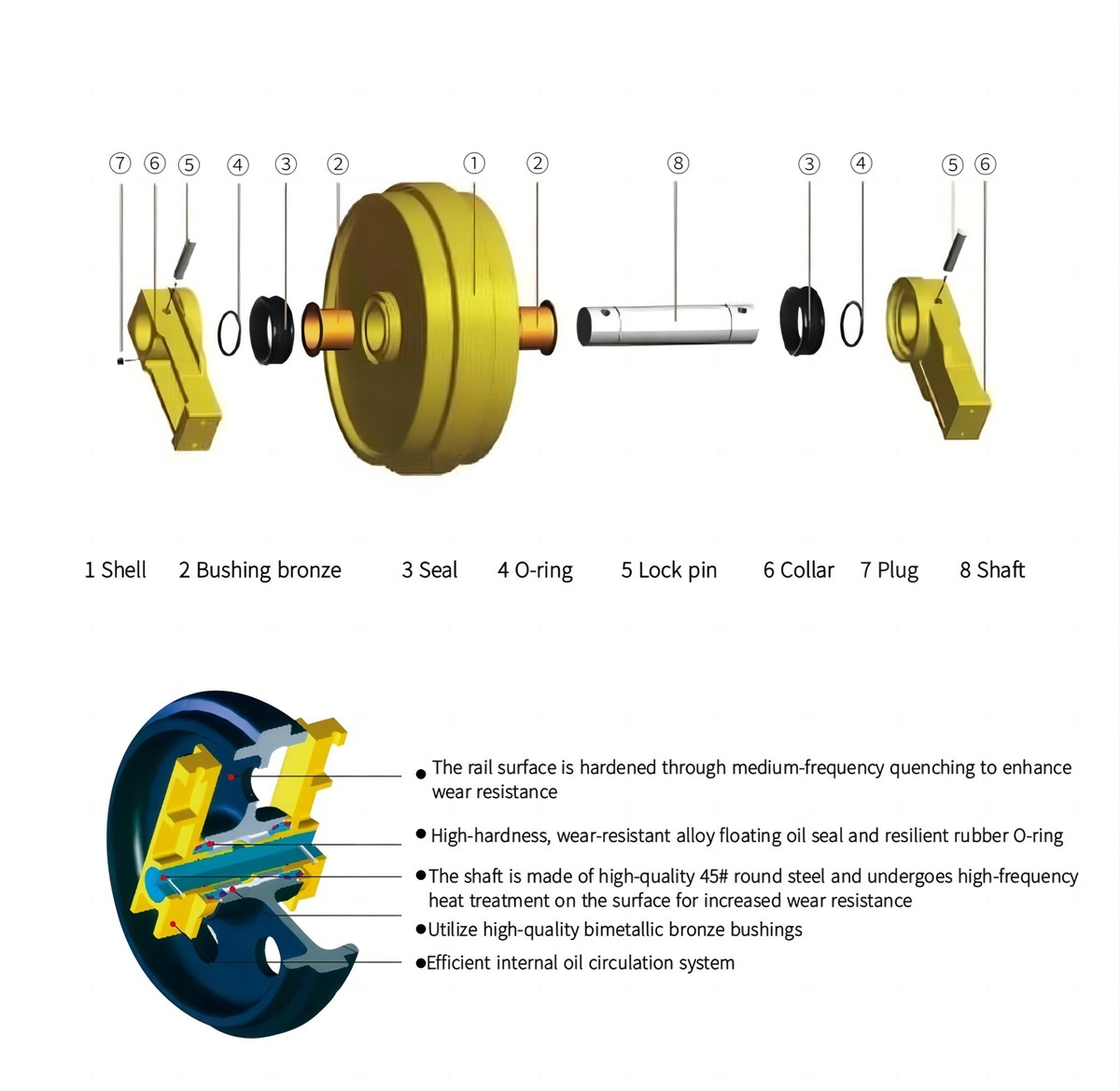

The D10 Dozer Idler Group boasts exceptional quality and unparalleled durability. Engineered with precision and built to withstand the toughest of terrains, this product exemplifies reliability and longevity. Elevate your heavy-duty machinery with this superior component that guarantees outstanding performance and longevity.

| Material | 50Mn/40MnB |

| Finish | Smooth |

| Colors | Black or yellow |

| Technique | Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness | HRC48-54,deepth:4mm-10mm |

| Warranty time | 2000 hour |

| MOQ | 2 piece |

| Delivery Time | Within 7-30 days after payments |

1. Superior Material Quality:

Our D10 Dozer Idler Group is manufactured with the highest grade materials available in the industry. We understand the importance of durability and reliability in heavy machinery, which is why we use only the finest materials that can withstand extreme conditions and provide long-lasting performance.

2. Rigorous Heat Treatment Process:

Our D10 Dozer Idler Group undergoes a stringent heat treatment process to ensure its exceptional strength and hardness. By subjecting the components to precise temperatures and controlled cooling, we enhance their resistance to wear, fatigue, and deformation. This process guarantees optimal performance even in the most demanding operating environments.

3. Strict Quality Control:

At our company, we adhere to strict quality control measures to ensure that every D10 Dozer Idler Group meets the highest standards. Our team of skilled inspectors meticulously examines each product, conducting thorough inspections and tests to validate its performance, precision, and overall quality. With our commitment to quality, you can trust that our products will exceed your expectations.

4. Carefully Selected Components:

Every single component of our D10 Dozer Idler Group is carefully selected to ensure its superior quality and compatibility. We understand that even the smallest part plays a crucial role in the overall performance of the machinery, and therefore, we guarantee that each component meets our strict criteria for excellence. This attention to detail ensures that our products function flawlessly and deliver exceptional results.

Model OEM Part No.

D8N/D8R 9W9989 Front Idler

D9N/D9R 7T2769 Dozer Idler

D10N/D10R 7T0962 Bulldozer ldler

D20/D21 103-30-00120 Idler For Dozer

D30/D31 113-30-00102 ldler For Bulldozer

D50 131-30-00285 Idler Fit For Komatsu Dozer

D65-8 144-30-00038 Idler

D65-12 14X-30-00112 ldler

D85-18 154-30-00293 Idler

D85-21 154-30-00770 Idler

D155A-1 175-30-00575 Idler

D355A-3 195-30-00283 Idler

D3C 9N4173 Idler Fit For CAT Dozer

D4D/D4E 1M8867 Idler Fit For CAT Bulldozer

D4H 190-1534 Idler

D4H 190-1551 Idler

D5 CR3190 Idler

D5H 161-7549 Idler

D6C/D6D 7T4562 ldler

D6H/D6R 2024296 Idler

D6H/D6R 2024304 Idler

D7F/D7G 7T4509 Idler

D8K CR4096 IdlerD8N/D8R 9W9987 Idler

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported