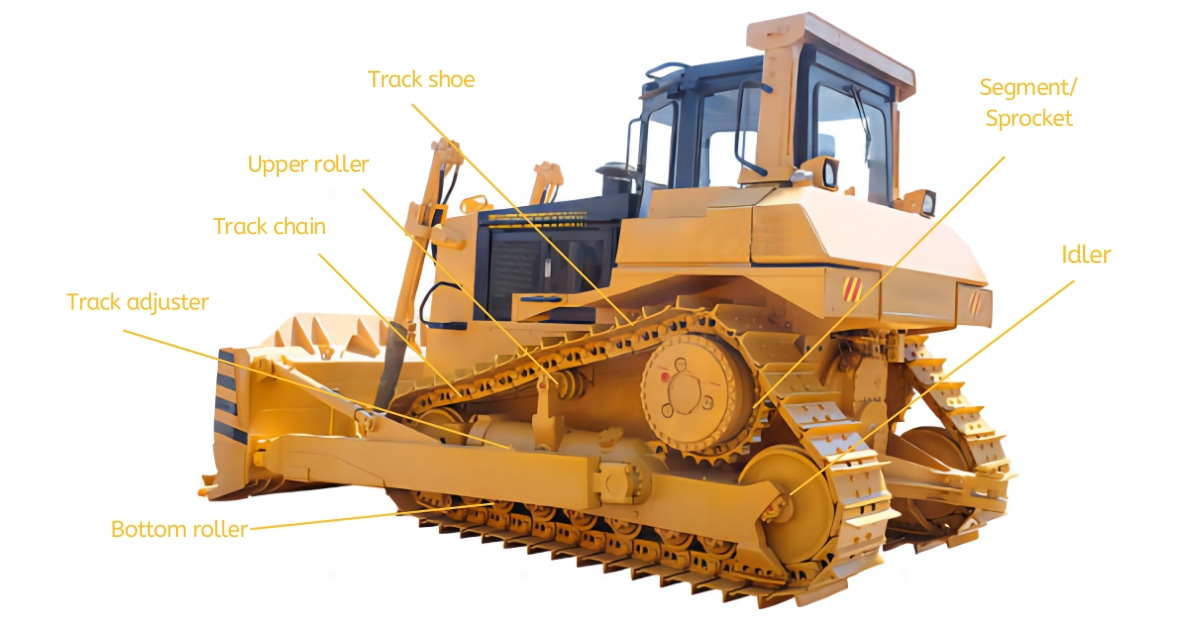

Dozer Undercarriage Parts

Our Carrier Rollers for dozers are precision-engineered components designed to optimize the performance and longevity of your dozer's undercarriage. Crafted with high-quality materials and advanced production techniques, these rollers ensure smooth operation and durability in challenging work environments. Choose reliability and performance with our Carrier Rollers for Dozer.

1、Introduction

High-Quality Materials: Crafted from premium materials such as 50Mn, 40MnB, and 40SiMnTi, our Carrier Rollers exhibit outstanding wear resistance, high strength, and optimal toughness. These qualities make them ideal for enduring harsh working conditions.

Advanced Production Techniques: Leveraging advanced production technologies, including precision machining, heat treatment, and quality control processes, we ensure that our Carrier Rollers meet or exceed industry standards. Our commitment to excellence is evident in every step of our production.

Enhanced Strength and Durability: Utilizing cutting-edge methods such as medium-frequency heating, induction hardening, and quenching and tempering, we enhance the strength and durability of our Carrier Rollers. This ensures they withstand the rigors of dozer operation over an extended lifespan.

Stringent Quality Control: Our rigorous quality control procedures guarantee that each Carrier Roller complies with the required standards for accuracy, hardness, and strength. We prioritize delivering products that meet or exceed customer expectations.

2、Why choose us

Unparalleled Customer Service: Our commitment to customer satisfaction is unwavering. We prioritize your needs, offering responsive and personalized service to ensure a seamless experience.

Reliable Product Knowledge: With years of industry expertise, we possess in-depth knowledge of dozer components. Count on us for accurate information, helpful insights, and guidance tailored to your requirements.

Efficient Order Processing: Time is of the essence. Experience swift and efficient order processing, ensuring your dozer's downtime is minimized, and you're back in action sooner.

Transparent Communication: We believe in transparent and clear communication. Stay informed throughout the process, from order placement to delivery, with regular updates on your purchase.

Flexible Solutions: Your needs are unique. We offer flexible solutions, accommodating custom orders, and addressing specific requirements to ensure you get precisely what your dozer demands.

3、Part numbers for carrier rollers for dozers, for your reference

| Model | OEM Part No. |

| 8P6256/9P2663 | D8K Carrier Roller |

| 8E0400 | D8N Carrier Roller |

| 141-30-00110 | D50-15~18 Carrier Roller |

| 141-30-00568 | D60-6 Carrier Roller |

| 14X-30-00141 | D65EX-12 Carrier Roller |

| 155-30-00233 | D80-18 Carrier Roller |

| 175-30-00515 | D150A-1/D155A-1 Carrier Roller |

| 6S3609 | D3B/D3C Carrier Roller |

| 6K9880/3K7962 | D4 Carrier Roller |

| 6Y3908 | D5H Carrier Roller |

| 6Y1781 | D6H/D6R Carrier Roller |

| 9S3570/5A8374 | D5B/D6B Carrier Roller |

| 3T3206/9S2730 | D6C/D6D Carrier Roller |

| 1P8717/2P3514 | D7F/D7G Carrier Roller |

4、FAQ

Q: Which dozer brands and models do your Carrier Rollers fit?

A: Yes, our Carrier Rollers cover major dozer brands and models on the market, including but not limited to Caterpillar, Komatsu, Volvo, and more. Provide us with your dozer model, and we'll ensure accurate matching of components.

Q: How is the quality of your products?

A: We adhere to using high-quality materials in the manufacturing of our components. Through advanced production processes and quality control, our products meet or exceed industry standards. All Carrier Rollers undergo rigorous testing to ensure wear resistance, strength, and durability.

Q: Can I get customized services?

A: Absolutely, we offer flexible solutions to meet your customization needs. Whether it's special sizes, custom designs, or other personalized requirements, we strive to accommodate.

Q: Are your prices competitive?

A: We are committed to providing competitive prices while maintaining product quality. Through efficient production processes and supply chain management, we work to ensure customers get value for their money.

Q: Do you have stock? What is the delivery time?

A: If the product is in stock, we usually ship within approximately one week after receiving the deposit. For stock availability and delivery times, feel free to contact our customer service team for detailed information.

Q: Do you provide after-sales service?

A: Yes, we offer after-sales service. If you encounter any issues during use or need support, we will do our best to provide timely technical assistance and solutions.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported