Dozer Undercarriage Parts

Discover the epitome of durability and precision with our exceptional range of Undercarriage Track Rollers. Crafted to perfection, these essential components offer unparalleled performance, ensuring seamless operation even in the most challenging terrains. Immerse yourself in the world of excellence as you rely on our Undercarriage Track Rollers for unmatched reliability and longevity.

| Material | 40MN2/35Mnbh |

| Finish | Smooth |

| Colors | Black or yellow/Customized |

| Technique | Forging /casting |

| Hardness | HRC37-49 |

| Process | Heat Treatment |

| Delivery Time | Within 15-30 days after payments |

| Package | Wooden pallets/boxes/plywood pallets/cartons |

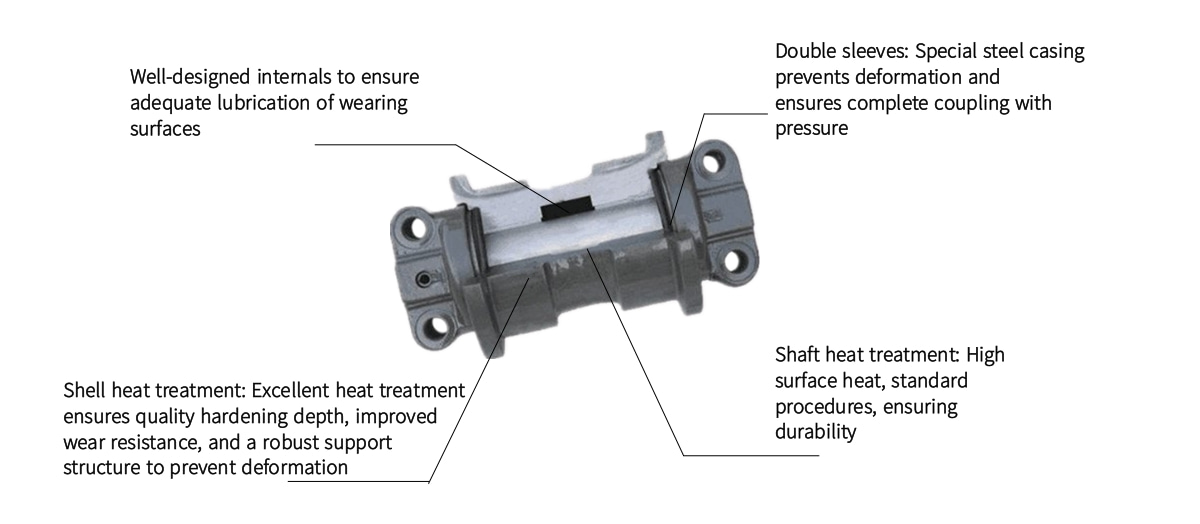

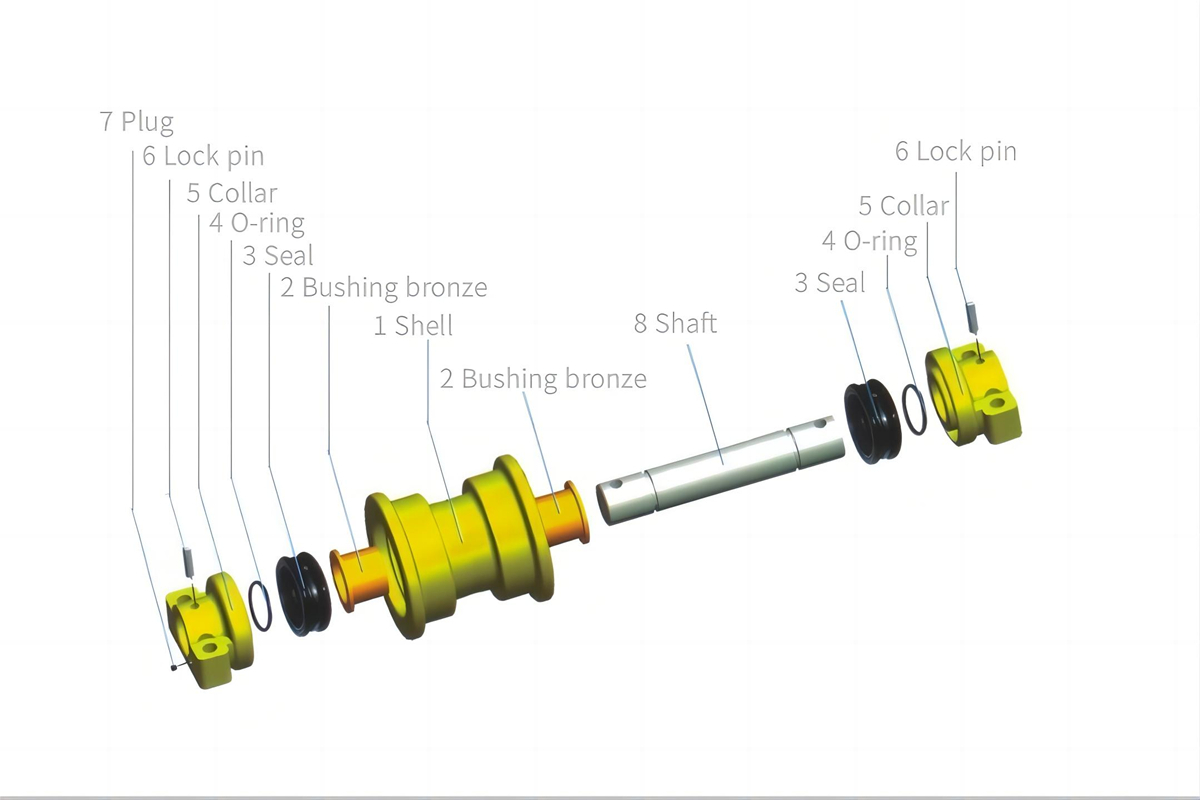

1. Superior Material:

Our Undercarriage Track Rollers are crafted using only the finest materials, guaranteeing exceptional durability and longevity. We understand the importance of quality in heavy-duty equipment, which is why our rollers are constructed using high-grade alloys that can withstand the toughest working conditions.

2. Rigorous Heat Treatment Process:

With utmost precision, our Undercarriage Track Rollers undergo a stringent heat treatment process. This process not only enhances the strength and hardness of the rollers but also ensures their resistance to wear, extending their service life substantially. Our commitment to maintaining optimal performance sets us apart in the industry.

3. Thorough Component Inspection:

Each component of our Undercarriage Track Rollers undergoes thorough inspection and testing before assembly. Our skilled technicians meticulously examine every single part to ensure its dimensional accuracy, structural integrity, and load-bearing capacity. By meticulously scrutinizing each component, we deliver rollers that meet the highest industry standards.

4. Reliable Performance in Various Working Conditions:

Versatility is key when it comes to undercarriage rollers. Our Undercarriage Track Rollers are designed to adapt to a wide range of working conditions, including rough terrains, extreme temperatures, and heavy loads. Their robust construction and precise engineering ensure consistent performance, making them a trusted choice in diverse environments.

| Model | OEM Part No. |

| D9N/D9R | 7T1253 Track Roller |

| D10N/D10R | 6Y0889 Track Roller |

| D31-16 | 113-30-00282 Track Roller |

| D41-6 | 124-30-52602 Track Roller |

| D50-15/D60-3 | 131-30-00322 Track Roller |

| D60-6 | 141-30-00578 Track Roller |

| D65-12 | 14X-30-00081 Track Roller |

| D80-12 | 154-30-00505 Track Roller |

| D80-18 | 155-30-00126 Track Roller |

| D85E-18 | 155-30-00117 Track Roller |

| D150A-1/D155A-1 | 175-30-00486 Track Roller |

| D155AX-3 | 17A-30-00080 Track Roller |

| D3B/D3C | 6S3607/3T4352 Track Roller |

| D4C/D4D | 7K8096/7K8084 Track Roller |

| D5 | 9S9539 Track Roller |

| D5H | 9P1363 Track Roller |

| D6C | 9S9403 Track Roller |

| D6D | 7G0423/9G8034 Track Roller |

| D6R | 120-5746 Track Roller |

| D6H | 7T4107 Track Roller |

| D7G | 9S0316/4S9051 Track Roller |

| D8N | 9W8706/7G9193 Track Roller |

| D8K | 6P4897/7S9041 Track Roller |

Model OEM Part No.

E311/312 151-9747/41-7346 Track Roller

E320/E200B 117-5045/8E-5034 Lower Roller

E322 163-4145/61-9396 Bottom Roller

E325 117-5046/6Y-1057 Track Roller Fit For CAT Excavator

E330 117-5047/6Y-2795 Track Roller

E450 863096/G643-00200B Track Roller

PC60-1/3 201-30-00050 Track Roller Fit For Komatsu Excavator

PC60-5/6 201-30-00062 Track Roller

PC60-6 21W-30-00021 Track Roller

PC60-7 201-30-00292 Track Roller

PC100-1/2/3/5 203-30-00140 Track Roller

PC100-6/PC120-6 203-30-00220 Track Roller

PC120-1/2/3/5 203-30-00140 Track Roller

PC200-1/2 205-30-00172 Track Roller

PC200-3 20Y-30-00130 Track Roller

PC200-5/6 20Y-30-00012 Track Roller

PC200-7 20Y-30-00015 Track Roller

PC220-1/2 205-30-00172 Track Roller

PC220-3 20Y-30-00130 Track Roller

PC220-5/6 20Y-30-00012 Track Roller

PC300-1/2 141-30-00578 Track Roller

PC300-3 207-30-00130 Track Roller

PC300-5/6 207-30-00150 Track Roller

PC400-3/5 208-30-00210 Track Roller

EX60-1 9046234/9066207 Track Roller Fit For Hitachi Excavator

EX60-2 9066970 Track Roller

EX60-3 9096970 Track Roller

EX60-5 9153152/9177016 Track Roller

EX100 9066508 Track Roller

EX100-2/3/5 9132600/9092522 Track Roller

EX120-1 9066508 Track Roller

EX120-2/3/5 9132600/9092522 Track Roller

EX200-1 9114617/9066510 Track Roller

EX200-2/3 9089173 Track Roller

EX200-5 9134243 Track Roller

EX220-1 9114618/9066509 Track Roller

EX220-2 9089173 Track Roller

EX220-3/5 9132602 Track Roller

EX270-1/2 9114682 Track Roller

EX270-5 9168173 Track Roller

EX300-1 9114619/9066690 Track Roller

EX300-2/3/5 9168173/9114682 Track Roller

EX400-1/2/3/5 4386648/9129347 Track Roller

SK100-1/SK120-1 24100N4042F2 Track Roller

K907B B90N0059F6 Track Roller

SK200-1 24100N5947F2 Track Roller

SK220-1 24100J11696F3 Track Roller

SK200-2/3 24100N5947F2 Track Roller

SK200-5/6 YN64D00013F1 Track Roller

SK300-1 24100N3856F3 Track Roller

SK330-6 LC64D00005F1 Track Roller

SH100/SH120 KNA0242/KNA0532 Track Roller

SH200 KRA1189 Track Roller

SH200 KRA1190 Track Roller

SH220 KBA0869 Track Roller

SH220 KBA0870 Track Roller

HD700 547-50800110 Track Roller

HD820 707-50800101 Track Roller

DH220 2270-1098 Track Roller

DH280/DH320 2270-9401A Track Roller

R200 E181-2002 Track Roller Fit For Hyundai Excavator

R210 81EL-20020 Track Roller

R210LC-7 81N6-11010 Track Roller

R290 81E9-2002 Track Roller

R290LC-7 81N8-11010 Track Roller

EC210 1181-00020 Track Roller

EC240 1181-00020 Track Roller

EC290 1181-01011 Track Roller

EC360 1081-01820 Track Roller

EC460 1081-01820 Track Roller

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported