Excavator Undercarriage Parts

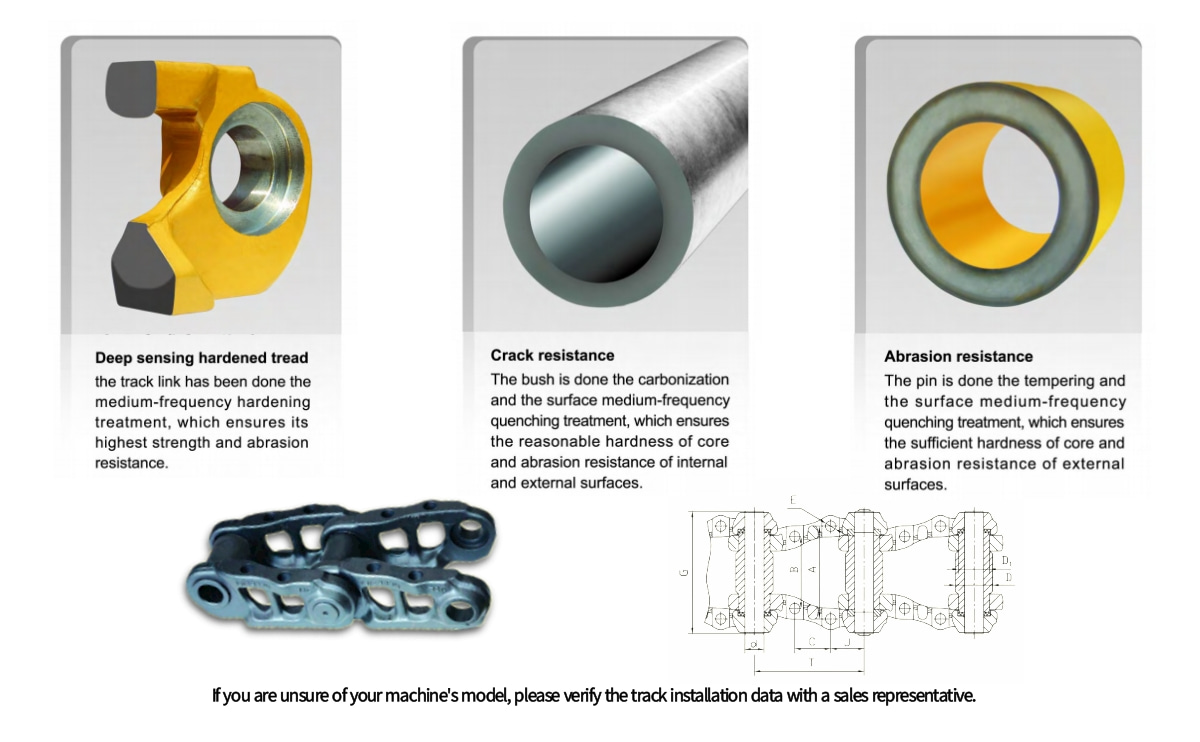

Excavator track chain is an essential component of an excavator, responsible for providing traction and movement to the machine. It consists of a series of connected links that run along the undercarriage of the excavator, interlocking with the sprockets, idlers, and rollers to form a continuous track. Solid design of track chains enables wear resistance and stress resistance for long time,The highly finished and deeply quenched chain link, pin sleeve and bush are stronger in wear resistance.

1、Introduction:

Our Excavator Track Chain is made of high-quality materials such as alloy steel and subjected to advanced heat treatment processes to ensure its durability and wear resistance. Our production process includes precision machining and strict quality control measures to ensure the assembly's dimensional accuracy and consistency.

We use a specialized production line for track chain, which includes a series of processes such as forging, heat treatment, and assembly. Each component of the assembly is carefully inspected and measured to ensure the final product meets our high-quality standards.

Our manufacturing processes ensure that our Excavator Track Chain has superior strength and performance, making it suitable for use in even the most demanding operating conditions. Additionally, our strict quality control measures ensure that our customers receive a reliable and long-lasting product.

2、Excavator model and part numer:

| Model & Part number | Model & Part number |

| E12OB 990648 | R290 175-8822 |

| E200B 096-4301 | R210 81EM-20010 |

| E311 4I7479 | R200 5601354 |

| E312 990648 | DH280 2272-6047 |

| E315 1028124 | DH220 2272-1025 |

| E320 9W9353 | DH200 2272-9004 |

| E325 6Y0854 | SK300 24100J15218F2 |

| E330 6Y2755 | SK200 24100J11338F2 |

| PC60-1 201-32-00113 | SK120 24100J12245F5 |

| PC60-3/5 201-32-00131 | SK60 24100N6311F2 |

| PC60-6 201-32-00200 | EX400-5 9133225 |

| PC60-7 201-32-00300 | EX400-2/3 9133225 |

| PC100-1/2 202-32-00116 | EX330-5 9156481 |

| PC100-3 202-32-00131 | EX300-5 9156481 |

| PC100-5 202-32-00201 | EX300-1/2/3 9070645 |

| PC100-6 202-32-00202 | EX270-5 9180884 |

| PC120-1/2 202-32-00131 | EX270-1/2 9070645 |

| PC120-3 202-32-00011 | EX220-5 9180319 |

| PC120-5/6 202-32-00101 | EX220-2/3 9093029 |

| PC200-1/2 205-32-00031 | EX220 9093029 |

| PC200-3 205-32-00051 | EX200-5 9135631 |

| PC200-5/6 20Y-32-00013 | EX200-2/3 9092517 |

| PC200-7 20Y-32-00300 | EX200-1 9066724 |

| PC220-1/2 206-32-00011 | EX120-5 9138747 |

| PC220-3 206-32-00032 | EX120-2/3 9092932 |

| PC220-5/6 206-32-00103 | EX120-1 9091951 |

| PC300-1 207-32-00010 | EX100-5 9143278 |

| PC300-2 207-32-00031 | EX100-2/3 9092929 |

| PC300-3/5 207-32-00100 | EX100 9091948 |

| PC300-6 207-32-00300 | EX60-5 9156478 |

| PC300-7 207-32-00310 | EX60-2/3 9096710 |

| PC400-1 208-32-00011 | EX60 9096710 |

| PC400-5 208-32-00101 | PC400-6 208-32-00300 |

3、FAQ

Terms & Conditions of Ordering:

① Payment Terms: T/T (Telegraphic Transfer)

② Delivery Term: Based on order quantity, normally it takes 25 days for production. Only 2 or 5 days if we have stock on your request size.

③ Transportation: Sample order: we suggest Courier express or by air. Bulk order: we suggest by air or by sea.

④ Quality & Service:

A. There will be strict inspection and testing for every order before shipping out.

B. Our sales team and Technical Support will response for your question within 24 hours (Holidays Excluded) through WhatsApp/Wechat: + 86 18850110101

4. Daily maintenance of excavator track chains is crucial for ensuring the equipment operates normally and extending its service life. Here are some important considerations based on my research:

Correct operating practices can significantly extend the lifespan of the tracks and reduce construction costs. This includes avoiding overloading and improper operating habits.

Regularly check the wear condition of the chains and ensure that all components receive proper lubrication. Incorrect oiling or oil change practices can severely impact the safety and effective usage time of the machine.

The chains should maintain appropriate tension; excessive tightness can lead to increased wear.

Timely replacement of severely worn chains and other related components, such as track links and bushings, is essential. Particularly when chains wear rapidly due to harsh working environments, they should be replaced promptly to avoid greater losses.

Adjust maintenance strategies based on the actual working conditions of the excavator to improve maintenance efficiency and reduce costs.

Implement a mandatory maintenance plan to prevent failures and safety hazards caused by equipment aging.

Provide technical training for operators to ensure they understand how to properly operate and maintain the excavator and its chains.

By following these maintenance measures, the lifespan of the excavator chains can be effectively extended, maintenance costs reduced, and work efficiency improved.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported