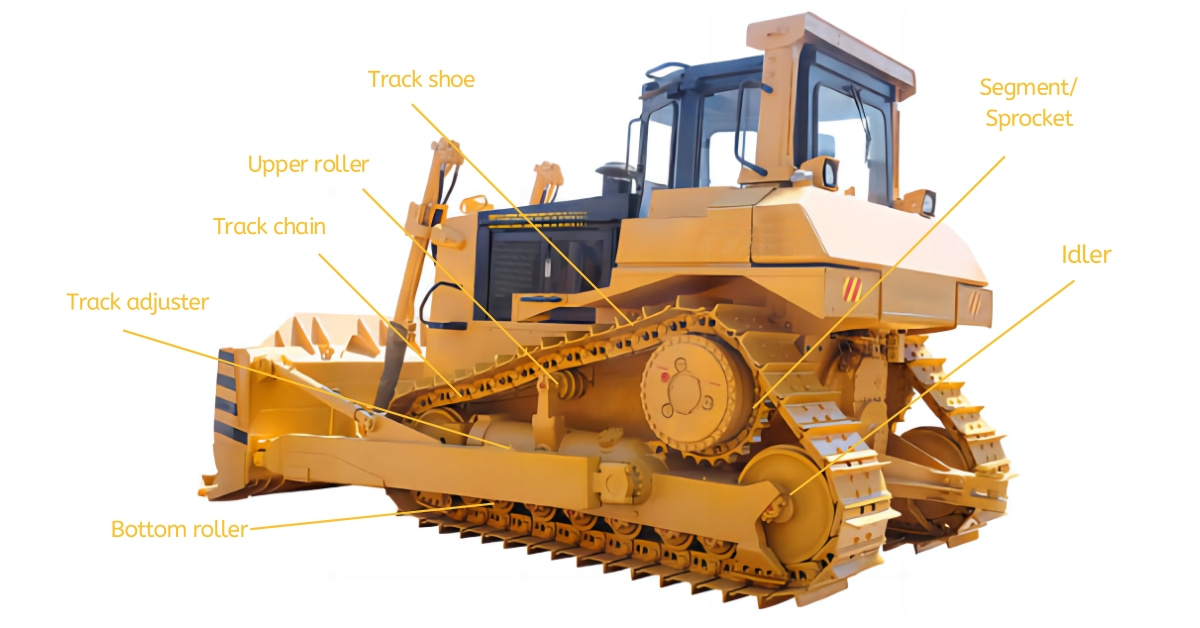

Dozer Undercarriage Parts

Our Komatsu undercarriage parts are designed with a focus on three key aspects: superior material quality, consistent reliability, and exceptional value.

Superior Material Quality

We use top-tier materials that are specifically chosen to withstand the demanding conditions faced by Komatsu machinery. This ensures that our undercarriage parts offer durability and long-lasting performance.

Consistent Reliability

Our rigorous production processes and stringent quality control measures guarantee that each part meets the highest standards. You can count on the consistent performance and reliability of our products, keeping your Komatsu equipment running smoothly.

Exceptional Value

We believe in delivering high-quality parts at competitive prices. Our products offer an outstanding balance between cost and performance, providing you with the best value for your investment.

As a professional supplier of Komatsu undercarriage parts, we understand the critical role these components play in the performance and longevity of your machinery. Our undercarriage parts are designed with precision, using top-quality materials and advanced manufacturing processes, ensuring that your Komatsu equipment operates at its best. With our expertise and commitment to excellence, we aim to provide you with the best products on the market, addressing any concerns you may have about sourcing these essential parts.

Industry-Leading Material Quality

We prioritize the use of superior materials in the production of our undercarriage parts. Our components are crafted from high-grade steel and other durable materials that withstand the toughest environments, ensuring long-lasting performance and reducing the need for frequent replacements.

Proven Reliability and Stability

As a specialized supplier, we have developed a deep understanding of what makes undercarriage parts reliable. Our products undergo stringent quality control tests at every stage of production, guaranteeing stable and consistent performance. This reliability translates to less downtime and more productivity for your operations.

Expert Manufacturing Processes

Our extensive experience in the industry allows us to employ advanced manufacturing techniques that ensure precision and quality in every part we produce. This expertise not only enhances the durability of our parts but also ensures perfect compatibility with your Komatsu equipment, eliminating concerns about fit and function.

Competitive Pricing with High Value

We offer our high-quality undercarriage parts at competitive prices, providing you with excellent value for your investment. Our focus on cost-effectiveness means you get top-tier products without the premium price tag, making it easier to manage your maintenance budget while maintaining high standards.

We understand that sourcing undercarriage parts can come with various concerns. Here’s how we alleviate those worries and earn your trust:

Guaranteed Compatibility

Our parts are specifically engineered to fit Komatsu models, ensuring seamless integration and optimal performance. We guarantee that our components will work perfectly with your machinery, reducing the risk of costly errors and downtime.

Reliable Supply and Timely Delivery

We pride ourselves on maintaining a dependable supply chain. Our robust inventory and efficient logistics ensure that you receive the parts you need when you need them, helping you avoid delays in your operations.

Transparent and Honest Business Practices

Trust is the foundation of our business. We are committed to transparency in all transactions, providing clear and detailed product information, honest pricing, and no hidden fees. Our goal is to build long-lasting relationships based on trust and reliability.

Comprehensive After-Sales Support

Our commitment to you doesn’t end with the sale. We offer dedicated after-sales support to assist with any questions or issues that may arise. Our professional team is always ready to help, ensuring that you are completely satisfied with your purchase.

Specialized Expertise:

With years of experience focused on Komatsu undercarriage parts, we bring specialized knowledge and expertise to every product we offer. Our deep understanding of Komatsu machinery ensures that our parts meet the highest standards of quality and performance.

Proven Track Record:

We have a proven track record of supplying reliable, high-quality parts to satisfied customers across various industries. Our clients trust us to deliver parts that enhance their equipment’s performance and lifespan.

Customer-Focused Approach:

Your satisfaction is our top priority. We listen to your needs and work closely with you to provide solutions that meet your specific requirements. Our customer-focused approach ensures that you receive not just parts, but also the support and service you need to succeed.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported