Dozer Undercarriage Parts

The undercarriage of a dozer is a critical component that directly impacts the machine’s performance, durability, and efficiency. As a professional manufacturer, we specialize in providing high-quality undercarriage parts that ensure your dozer operates smoothly across the toughest terrains.

1. Introduction

This page highlights our extensive range of dozer undercarriage parts, including track rollers, track chains, idlers, segments, and carrier rollers, and emphasizes the advantages of choosing our products.

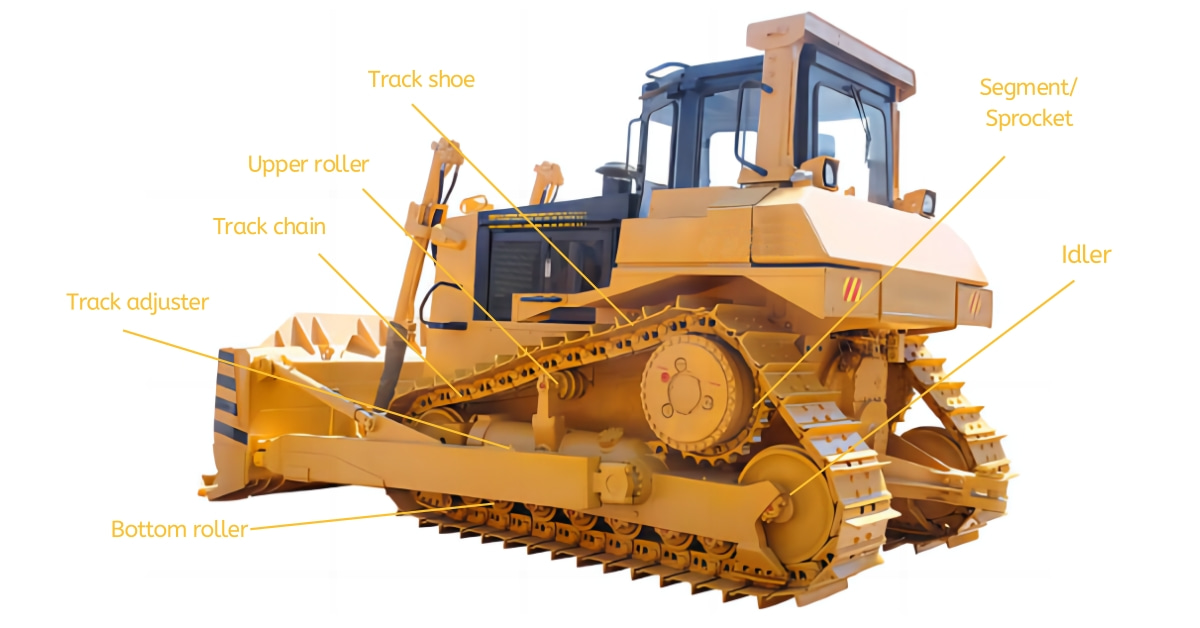

The undercarriage system of a dozer includes several key components that work together to distribute the weight of the machine, provide traction, and maintain stability. Understanding the function and importance of each part is essential for maintaining optimal performance and reducing downtime.

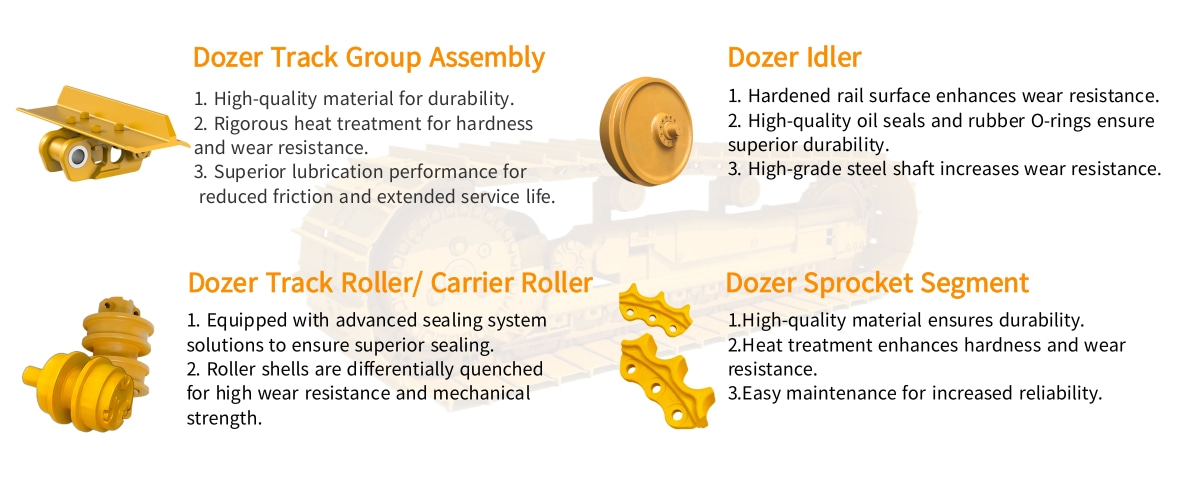

Track rollers support the weight of the dozer and guide the track around the undercarriage. They are crucial for ensuring smooth and stable movement, particularly in uneven or rugged environments. Our track rollers are designed to withstand high-impact conditions, offering superior wear resistance and longevity.

The track chains connect the track shoes and work in conjunction with the sprocket to move the dozer forward or backward. Our track chains are engineered for maximum durability, reducing the risk of breakage and minimizing maintenance needs. Their robust design ensures they can handle heavy loads and harsh working conditions.

Idlers maintain the proper tension of the track chains, helping to prevent slack and ensuring smooth operation. Our idlers are built with precision to reduce wear and tear on the track system, extending the lifespan of both the chains and the track shoes. They are made from high-quality materials that resist deformation under pressure.

Segments, also known as sprocket segments, engage with the track chains to drive the tracks. Our segments are manufactured to precise specifications to ensure a perfect fit and optimal power transmission. The materials used in our segments are selected for their toughness and ability to resist wear, even in the most demanding applications.

Carrier rollers support the upper side of the track, ensuring that the track remains aligned and properly tensioned. Our carrier rollers are designed to handle heavy loads and resist wear, providing long-lasting performance in all types of operating environments.

With years of experience in manufacturing undercarriage parts, we have developed a deep understanding of the unique challenges faced by dozer operators. Our expertise allows us to produce parts that not only meet but exceed industry standards, providing reliable performance in the field.

We use only the finest materials in the production of our undercarriage parts. From high-strength steel to advanced alloys, every component is designed to withstand the rigors of heavy-duty use. Our commitment to quality ensures that our parts offer exceptional wear resistance, durability, and strength.

Our parts are manufactured using state-of-the-art technology and precision engineering processes. This ensures that each component fits perfectly within the undercarriage system, reducing the risk of failure and enhancing the overall performance of your dozer.

Quality is at the heart of our manufacturing process. Each undercarriage part undergoes rigorous testing and inspection to ensure it meets our exacting standards. From dimensional accuracy to material hardness, every detail is checked to guarantee that our parts deliver superior performance.

We understand that different applications require different solutions. That’s why we offer customization options for our undercarriage parts, allowing you to specify dimensions, materials, and other characteristics to suit your specific needs. Our team is dedicated to providing you with the exact parts you need to keep your dozer running smoothly.

Our efficient production processes and strategic sourcing allow us to offer high-quality undercarriage parts at competitive prices. We are committed to providing you with the best value for your investment, ensuring that you receive top-tier parts without breaking your budget.

We know that downtime can be costly, which is why we prioritize reliable delivery and exceptional customer support. Our logistics team ensures that your order is delivered on time, and our technical support team is always available to assist with installation, maintenance, or any other questions you may have.

Our undercarriage parts are compatible with a broad range of dozer models from leading manufacturers. Whether you are operating a small dozer for residential work or a large machine for mining or construction, we have the right parts to fit your needs.

Our undercarriage parts are designed to perform in diverse environments, from muddy construction sites to rocky mining terrains. Their robust construction ensures reliable performance in all types of operating conditions, helping to maximize the uptime of your equipment.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported