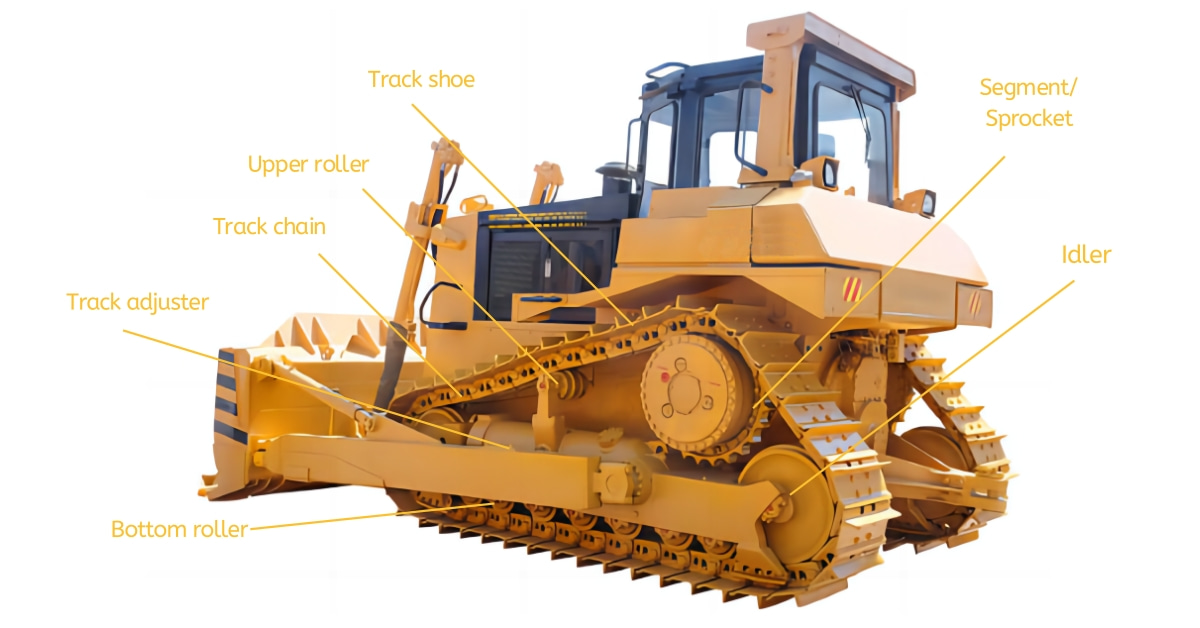

Dozer Undercarriage Parts

Our robust and reliable Track Roller Dozer is an essential tool for all heavy-duty construction needs. Designed with precision and durability in mind, it effortlessly maneuvers through even the toughest terrains, ensuring the utmost efficiency and productivity. With its advanced technology and uncompromising performance, our Track Roller Dozer is the perfect companion for any construction project, delivering exceptional results every time.

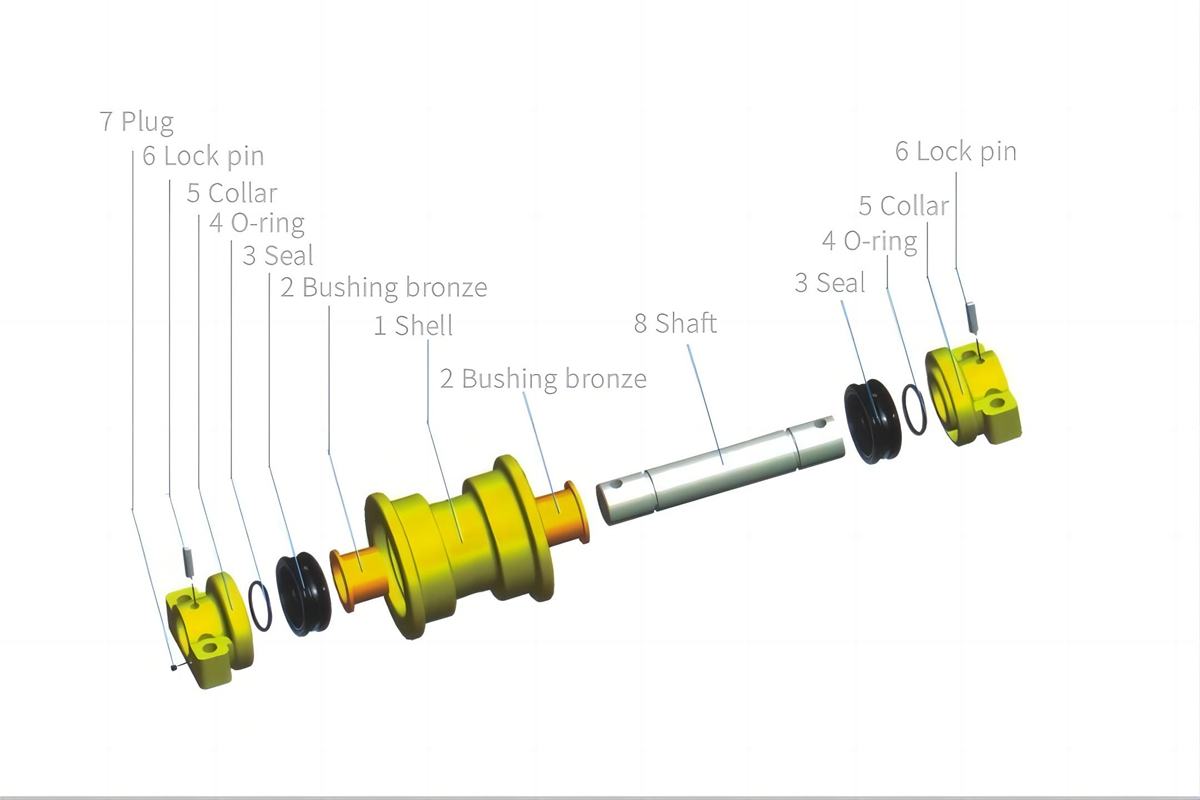

| Material | 40MN2/35Mnbh |

| Finish | Smooth |

| Colors | Black or yellow/Customized |

| Technique | Forging /casting |

| Hardness | HRC37-49 |

| Process | Heat Treatment |

| Delivery Time | Within 15-30 days after payments |

| Package | Wooden pallets/boxes/plywood pallets/cartons |

| Model | OEM Part No. |

| D9N/D9R | 7T1253 Dozer Track Roller |

| D10N/D10R | 6Y0889 Bulldozer Track Roller |

| D31-16 | 113-30-00282 Track Roller For Dozer |

| D41-6 | 124-30-52602 Track Roller Fit For Komatsu |

| D50-15/D60-3 | 131-30-00322 Track Roller |

| D60-6 | 141-30-00578 Track Roller |

| D65-12 | 14X-30-00081 Track Roller |

| D80-12 | 154-30-00505 Track Roller |

| D80-18 | 155-30-00126 Track Roller |

| D85E-18 | 155-30-00117 Track Roller |

| D150A-1/D155A-1 | 175-30-00486 Track Roller |

| D155AX-3 | 17A-30-00080 Track Roller |

| D3B/D3C | 6S3607/3T4352 Dozer Bottom Roller |

| D4C/D4D |

7K8096/7K8084 Track Roller Fit For CAT dozer |

| D5 | 9S9539 Bottom Roller For Sale |

| D5H | 9P1363 Track Roller |

| D6C | 9S9403 Track Roller |

| D6D | 7G0423/9G8034 Track Roller |

| D6R | 120-5746 Track Roller |

| D6H | 7T4107 Track Roller |

| D7G | 9S0316/4S9051 Track Roller |

| D8N | 9W8706/7G9193 Track Roller |

| D8K | 6P4897/7S9041 Track Roller |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported