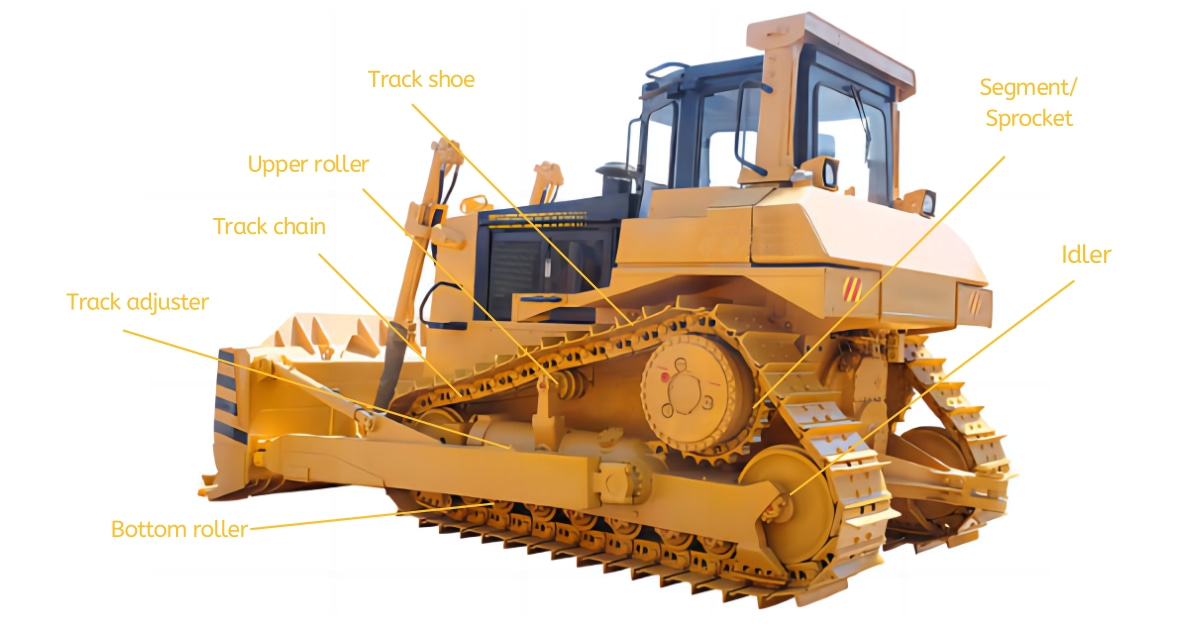

Dozer Undercarriage Parts

Track links are a crucial component in the undercarriage of excavators, bulldozers, loaders, and other tracked machinery. These links form the foundation of the track system, enabling the machinery to move efficiently across various terrains. We specialize in manufacturing high-quality track links that offer superior durability, reliability, and performance in demanding environments.

Track links generally come in two types: oil-sealed (lubricated) chains and dry chains. Each type is designed to meet specific operational needs and conditions.

Oil-sealed chains, often referred to as lubricated chains, are designed with internal lubrication that significantly reduces friction between the pin and bushing. This type of chain is commonly used in bulldozers and loaders due to its ability to operate smoothly under heavy loads and in harsh environments.

Dry chains, on the other hand, do not have internal lubrication and are often used in machinery that operates in less abrasive environments or where lower operating costs are a priority. These chains are more common in excavators, where the operational loads are typically different from those in bulldozers and loaders.

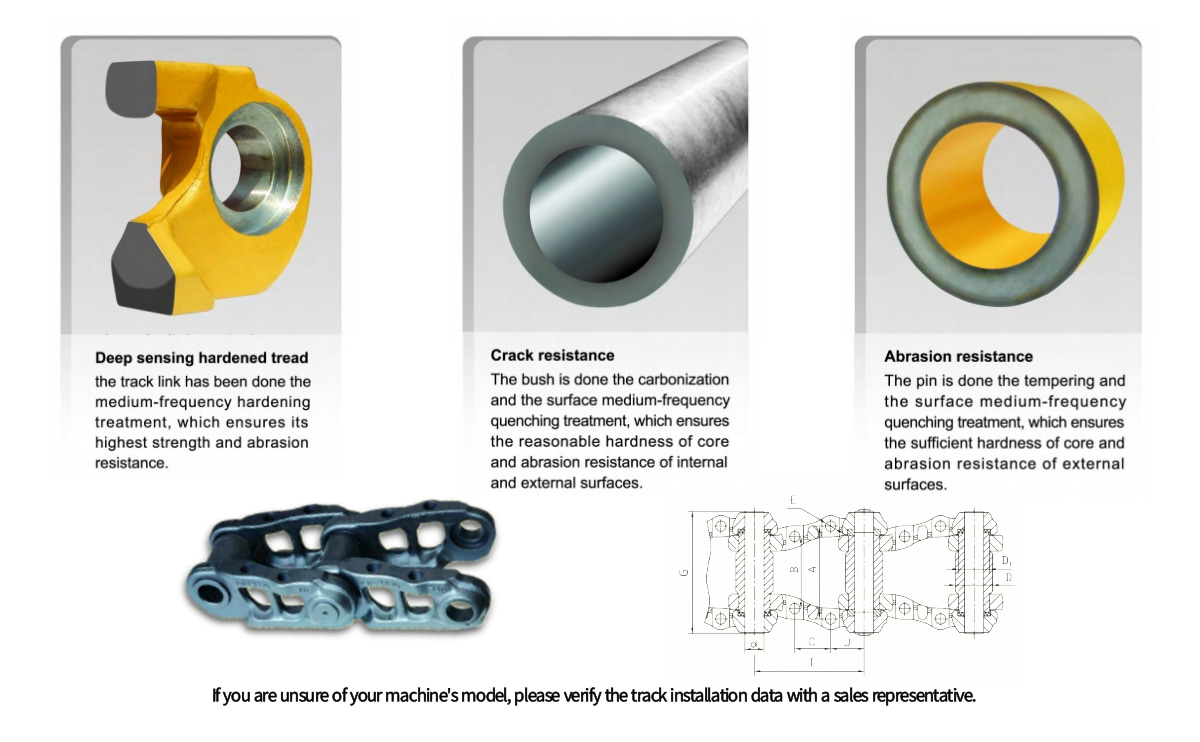

We leverage years of expertise and state-of-the-art technology to produce track links that meet the highest standards of quality and durability. Our manufacturing processes are designed to ensure precision and consistency in every link we produce.

The longevity and performance of track links depend heavily on the materials used. We select only the finest steel alloys, known for their superior toughness and wear resistance, to manufacture our track links.

Our track links undergo a rigorous heat treatment process to improve their hardness and wear resistance. This process ensures that the links can withstand the extreme conditions of heavy machinery operations.

We offer a wide variety of track links to suit different types of heavy machinery, including excavators, bulldozers, and loaders. Whether you need oil-sealed chains for heavy-duty applications or dry chains for more economical operations, we have the perfect solution for your needs.

Our track links are designed to withstand the toughest working conditions, offering exceptional resistance to wear and tear. This durability ensures that your machinery remains operational for longer, reducing the need for frequent replacements.

A well-maintained track link system ensures that your machinery operates at peak efficiency. Our track links are engineered to minimize friction and distribute load evenly, enhancing the overall performance of your equipment.

We understand the importance of minimizing downtime in your operations. That’s why we maintain a large inventory of track links, ready for immediate shipment. Our efficient logistics ensure that you receive your parts quickly, keeping your projects on schedule.

Quality is at the heart of everything we do. Our track links undergo strict quality control checks at every stage of production to ensure that they meet our exacting standards.

We believe in providing more than just products—we provide solutions. Our knowledgeable customer service team is always ready to assist you with product selection, technical support, and after-sales service.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported