Dozer Undercarriage Parts

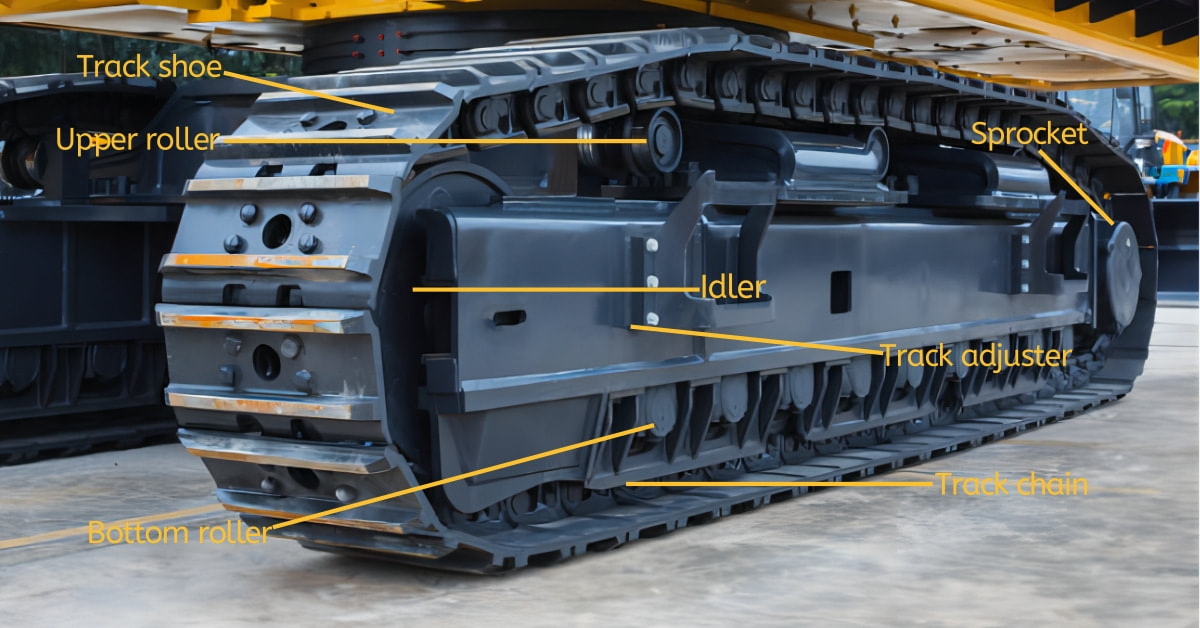

The idler is more than just a support wheel in the excavator's undercarriage system—it's a crucial component that directly impacts the performance and durability of the entire track system. Positioned at the front or rear of the track frame, the idler helps maintain proper track tension, reduces wear on the other components, and contributes to the overall stability of the machine. At Futeng Machinery, we understand the significance of these roles, and that's why we focus on delivering idlers that offer unmatched performance and longevity.

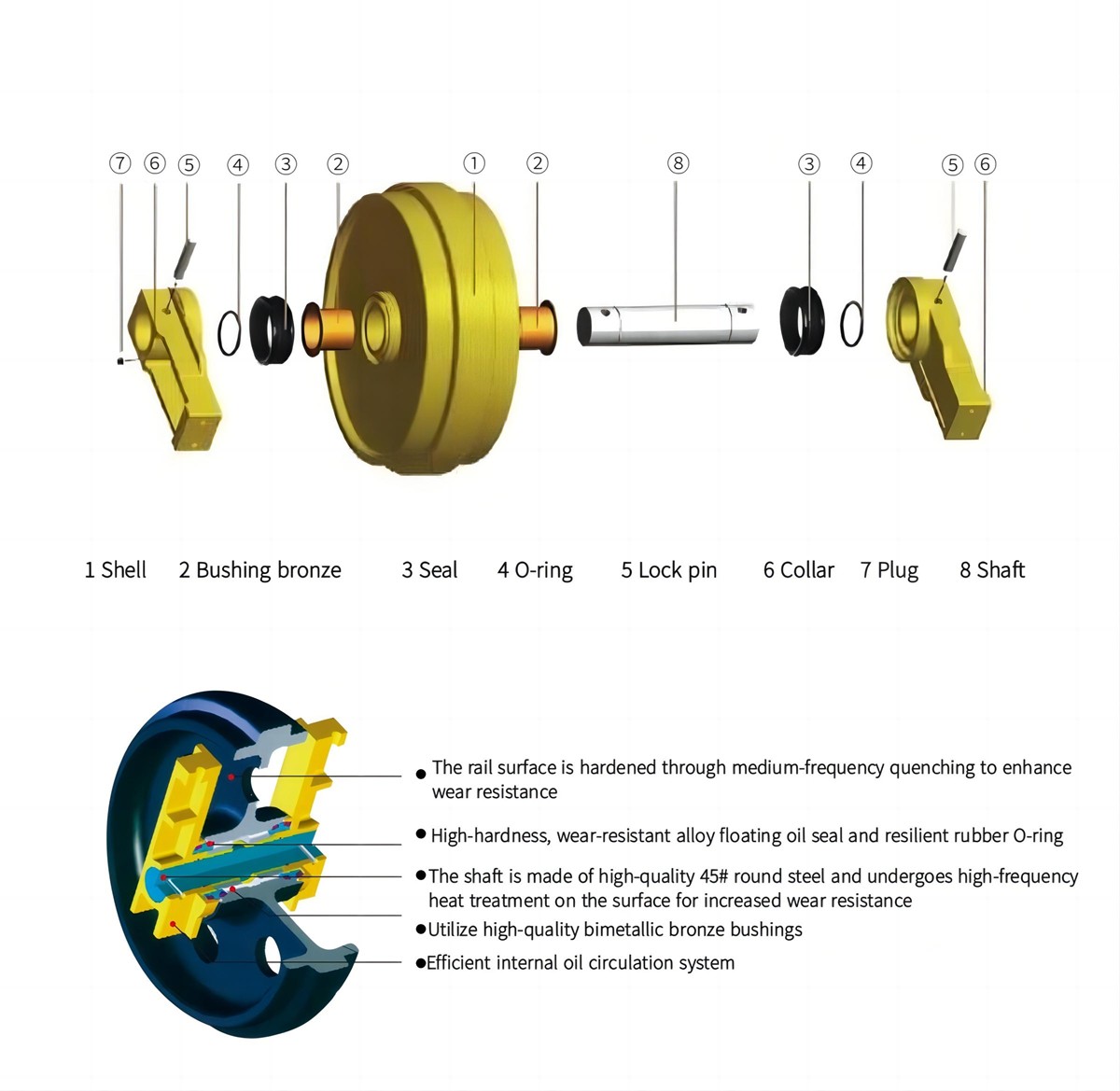

Durability is key to the performance of any undercarriage component. Our idlers are made from premium-grade materials that are carefully selected for their toughness and wear resistance. These materials not only ensure the longevity of the idler but also reduce the frequency of maintenance and replacement.

We employ advanced manufacturing techniques to produce idlers that are consistent in quality and performance. Our processes include state-of-the-art machining and heat treatment to ensure each idler meets the highest standards of durability and precision.

How to Properly Inspect and Maintain the Idler of an Excavator to Extend Its Lifespan?

To properly inspect and maintain the idler of an excavator and extend its lifespan, the following steps should be followed:

Maintain Proper Track Tension: Avoid over-tensioning, as this can cause the idler's spring tension to act on the track pins and bushings, leading to premature wear. Regularly check and adjust the track tension to maintain standard levels.

Regularly Inspect for Wear: Timely replacement of excessively worn idlers is crucial to avoid impacting the excavator's performance. Check for wear and damage on the track rollers, drive sprockets, and idlers, and repair as necessary.

Remove Foreign Objects: When there is oil, sand, dirt, or other debris on the surface of the idler and tensioning cylinder, it needs to be cleaned to prevent oil seal failure and leakage. Clean the track of mud, sand, and gravel to keep the idler, track rollers, and other components clean.

Lubrication: The idler's cushioning rebound spring assembly contains strong springs that require regular greasing to reduce wear and extend service life.

Safety Precautions: When performing any maintenance work, pay attention to safety measures, such as prohibiting the arbitrary disassembly of the rebound spring assembly to prevent serious personal injury from the spring popping out.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported