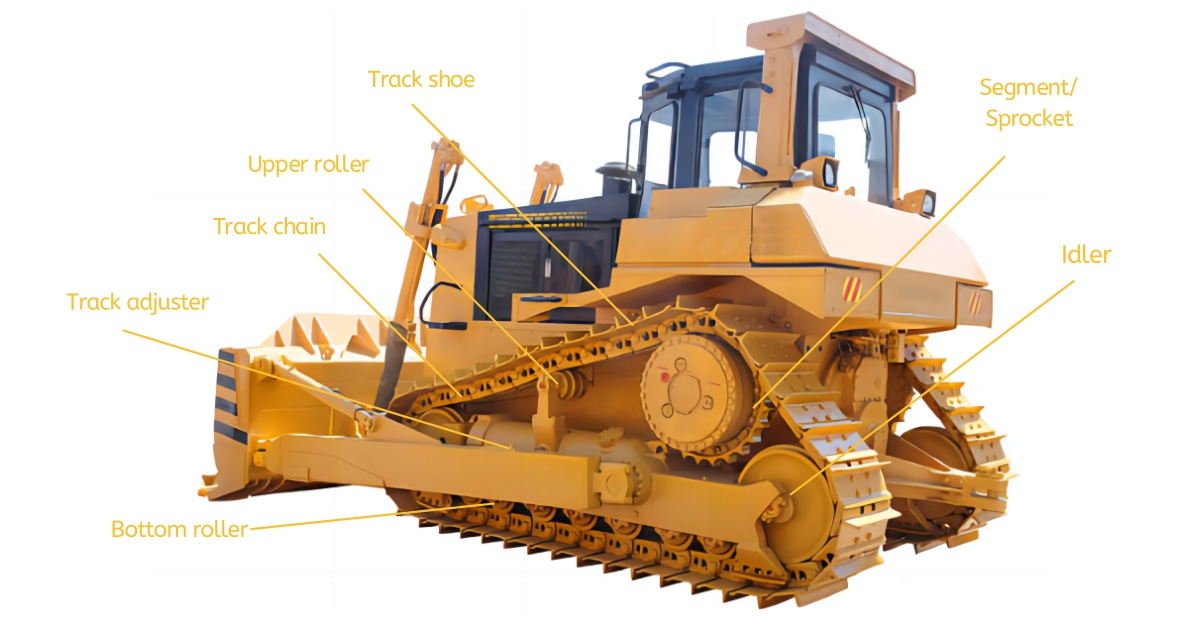

Dozer Undercarriage Parts

As a specialized manufacturer of dozer undercarriage parts, we pride ourselves on delivering products that are crafted with precision and care. Our commitment to excellence is reflected in every aspect of our production process, from the careful selection of materials to the rigorous quality management practices we employ.

Premium Material Selection

We meticulously choose the best materials to ensure that our undercarriage parts offer superior durability and performance. This careful material selection process is the foundation of our products' long-lasting reliability.

Professional Production

With extensive experience and advanced manufacturing techniques, we produce parts that meet the highest industry standards. Our expertise allows us to create components that are perfectly suited for CAT dozers, ensuring optimal fit and function.

Stringent Quality Management

Quality is at the heart of everything we do. Our robust quality management system involves multiple inspections and testing stages to guarantee that every part meets our exacting standards before it reaches our customers.

When it comes to maintaining your CAT dozer, choosing the right undercarriage parts is essential for ensuring optimal performance and longevity. As a dedicated manufacturer of CAT dozer undercarriage parts, we understand the importance of high-quality materials, professional production, and stringent quality management. Our products are designed to meet the exact needs of your machinery, providing you with peace of mind and exceptional value.

Superior Material Selection

One of the key factors in the durability and performance of undercarriage parts is the quality of the materials used. We carefully select only the finest materials, such as high-grade steel, that can withstand the extreme conditions faced by CAT dozers. This ensures that our parts not only last longer but also perform better, reducing the need for frequent replacements and minimizing downtime.

Customer Pain Point: Inferior materials can lead to premature wear and costly repairs.

Our Solution: By using premium materials, we offer parts that are built to last, saving you time and money in the long run.

Professional Production Expertise

Our production processes are guided by years of industry experience and advanced manufacturing techniques. Each part is crafted with precision to ensure a perfect fit and seamless integration with your CAT dozer. This professional approach to production means that our parts perform consistently, even under the most challenging conditions.

Customer Pain Point: Poorly manufactured parts can cause operational inefficiencies and compatibility issues.

Our Solution: Our expert production guarantees that each part meets the highest standards, ensuring reliable performance and compatibility with your equipment.

Rigorous Quality Management

Quality is not just a priority—it’s our promise. Our comprehensive quality management system includes multiple inspection points throughout the production process. We test each part to ensure it meets our strict criteria for durability, fit, and performance. Only parts that pass these rigorous checks make it to our customers.

Customer Pain Point: Inconsistent quality can lead to unexpected failures and operational interruptions.

Our Solution: With our stringent quality controls, you can trust that our parts will deliver the consistency and reliability your operations depend on.

Comprehensive After-Sales Support

We believe that our responsibility to you extends beyond the sale. Our dedicated after-sales support team is here to assist you with any questions or concerns, providing expert guidance and assistance whenever you need it. Whether it’s helping you choose the right parts or offering advice on maintenance, we are committed to your satisfaction.

Customer Pain Point: Lack of support can leave you stranded when issues arise.

Our Solution: Our after-sales service ensures you have the support you need, giving you confidence in your purchase and ensuring long-term success.

Compatibility and Fit:

Our parts are designed specifically for CAT dozers, ensuring perfect compatibility. You won’t have to worry about adjustments or modifications that could lead to operational issues.

Longevity and Durability:

Thanks to our superior materials and production processes, our parts are built to last. This longevity translates to fewer replacements and lower overall maintenance costs.

Cost-Effectiveness:

While we prioritize quality, we also offer our parts at competitive prices. This means you get the best value without compromising on the performance or reliability of your equipment.

Timely Delivery:

We understand the importance of minimizing downtime. Our efficient supply chain and logistics ensure that you receive your parts promptly, keeping your operations running smoothly.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported