Dozer Undercarriage Parts

Crafted with utmost precision and utilizing premium materials, our dozer Idlers guarantee unparalleled reliability and durability. Elevate your operations with this exceptional product that exceeds expectations and ensures optimal performance every time.

Key Features:

Key Features:

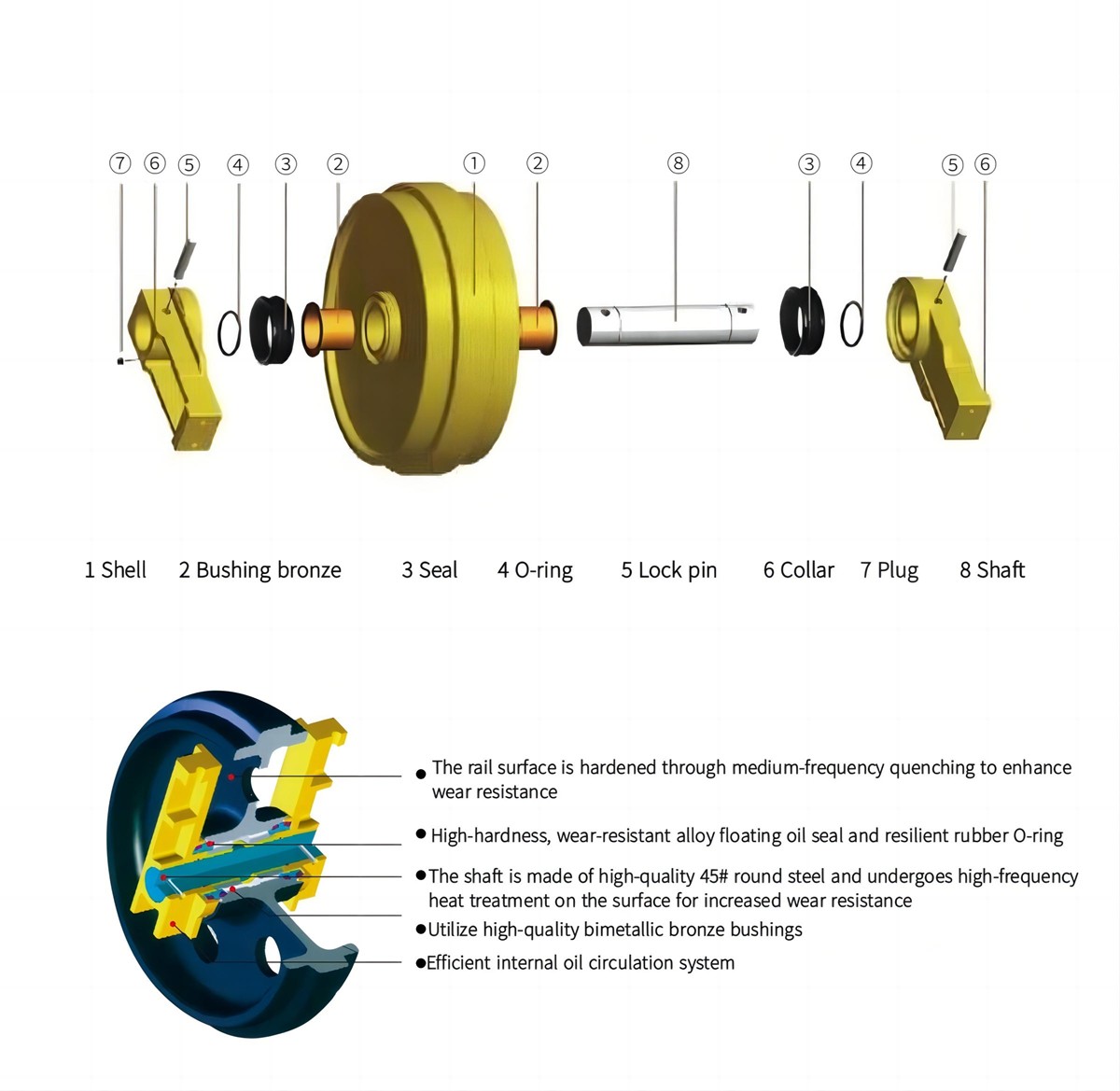

1. Premium Material: Constructed with high-grade steel, our Dozer Idler boasts remarkable strength and durability. The carefully selected materials guarantee longevity, enabling it to withstand heavy loads and harsh working conditions.

2. Impeccable Processing: Our Dozer Idler undergoes advanced processing techniques, showcasing a flawless finish and precision engineering. The meticulous attention to detail in its production enhances its overall performance and maximizes operational efficiency.

3. Specialized Heat Treatment: To ensure supreme resilience and extended lifespan, our Dozer Idler undergoes a specialized heat treatment process. This meticulous procedure enhances its wear resistance, reducing the risk of premature wear and tear, and allows for prolonged and uninterrupted operation.

4. Stringent Quality Inspection: Each Dozer Idler undergoes rigorous quality inspections throughout its production stages. We adhere to strict industry standards, guaranteeing that only the highest-grade products are delivered. Our focus on quality control establishes trust and confidence among our valued customers.

In summary, our Dozer Idler is a superior choice for those seeking excellence in construction machinery. With its premium materials, impeccable processing, specialized heat treatment, and stringent quality inspection, this extraordinary equipment ensures peak performance, durability, and reliability in the most demanding working environments. Partner with us today and experience the pinnacle of productivity and quality.

Why Choose Us

1. Unmatched Expertise in Production: With years of experience in the industry, we have gained unmatched expertise in manufacturing top-notch dozer idlers. Our team of skilled professionals ensures that every single product meets the highest quality standards, guaranteeing optimal performance and longevity.

2. Impeccable Pre and Post-sales Service: At our company, customer satisfaction is our top priority. From the moment you contact us to the after-sales support, our dedicated and knowledgeable team is always ready to assist you. We are committed to addressing all your queries and concerns promptly, providing you with the best buying experience possible.

3. Wide Range of Products: We offer a diverse range of dozer idlers, catering to different models and specifications. Whether you require idlers for small-scale projects or heavy-duty industrial applications, we have got you covered. Our extensive product selection ensures that you can find the perfect idler to suit your specific requirements.

4. Timely and Efficient Delivery: We understand the importance of timely delivery in the fast-paced industry of machinery and equipment. With our well-established logistics network, we ensure swift and efficient delivery of your ordered dozer idlers. Rest assured, your products will reach your doorstep in a prompt and intact manner.

5. Commitment to Excellence: Our relentless pursuit of excellence sets us apart from the competition. We are dedicated to providing you with the finest quality dozer idlers, impeccable service, and a hassle-free buying process. When you choose us, you are choosing a company that is committed to your success and satisfaction.

FAQ

Q: What distinguishes your dozer idlers from competitors in terms of quality?

A: Our dozer idlers stand out from competitors due to their superior quality and durability. We ensure that each idler is manufactured with precision using high-grade materials and advanced technology. This guarantees optimal performance, extended lifespan, and reduced maintenance costs for your machinery.

Q: Can you provide idlers that are compatible with various dozer models?

A: Absolutely! We offer a comprehensive range of dozer idlers that are compatible with a wide variety of dozer models, ensuring that we can meet the diverse needs of our global clientele. Our expert team is highly knowledgeable and can assist you in selecting the perfect idler specifically tailored to your machinery.

Q: How do I know if your dozer idlers are reliable for my projects?

A: Our dozer idlers undergo rigorous testing procedures to ensure their reliability and performance under demanding working conditions. We employ strict quality control measures throughout the manufacturing process, guaranteeing that each idler meets and exceeds industry standards. Rest assured, our idlers will provide you with the support and stability you need for your projects.

Q: Can you provide customizable options for the dozer idlers?

A: Certainly! We understand that every project has unique requirements, and we are able to offer customizable options for our dozer idlers. Whether it be specific dimensions, materials, or surface treatments, our team will work closely with you to provide a tailor-made solution that perfectly suits your needs.

Q: What is your shipping and delivery process for international orders?

A: We have a well-organized shipping and delivery process for international orders, ensuring timely and secure delivery to your designated location. We collaborate with trusted logistics partners who specialize in global shipping, enabling us to provide efficient and reliable services. Rest assured, your dozer idlers will arrive safely at your doorstep.

Dozer Idler Part Number

Model OEM Part No.

D8N/D8R 9W9989 Front Idler

D9N/D9R 7T2769 Dozer Idler

D10N/D10R 7T0962 Bulldozer ldler

D20/D21 103-30-00120 Idler For Dozer

D30/D31 113-30-00102 ldler For Bulldozer

D50 131-30-00285 Idler Fit For Komatsu Dozer

D65-8 144-30-00038 Idler

D65-12 14X-30-00112 ldler

D85-18 154-30-00293 Idler

D85-21 154-30-00770 Idler

D155A-1 175-30-00575 Idler

D355A-3 195-30-00283 Idler

D3C 9N4173 Idler Fit For CAT Dozer

D4D/D4E 1M8867 Idler Fit For CAT Bulldozer

D4H 190-1534 Idler

D4H 190-1551 Idler

D5 CR3190 Idler

D5H 161-7549 Idler

D6C/D6D 7T4562 ldler

D6H/D6R 2024296 Idler

D6H/D6R 2024304 Idler

D7F/D7G 7T4509 Idler

D8K CR4096 Idler

D8N/D8R 9W9987 Idler

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported