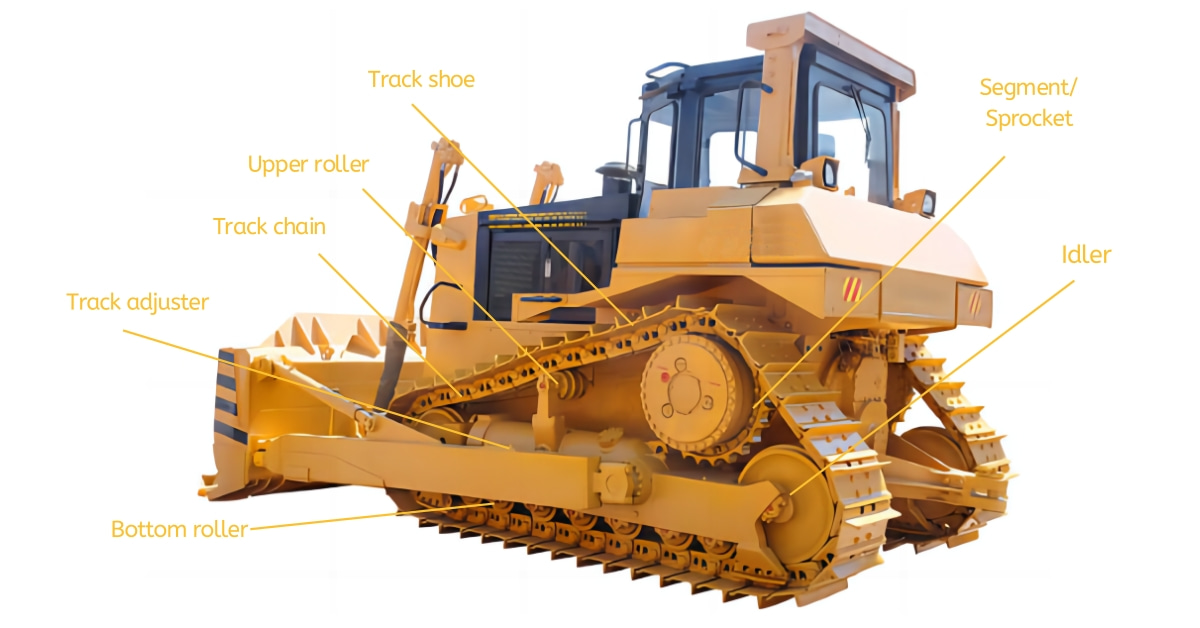

Dozer Undercarriage Parts

Our Dozer Chain is the ideal choice for contractors, equipment dealers, and maintenance professionals seeking a reliable, high-performance solution for their bulldozer and heavy equipment needs. With its exceptional strength, durability, and wear resistance, our Dozer Chain delivers unparalleled performance, reducing downtime and maintenance costs while maximizing productivity in the most demanding work environments.

The daily maintenance of dozer chains primarily includes the following aspects:

Regular Inspection and Lubrication: Regular manual oil dripping lubrication of dozer chains is essential to reduce abrasive wear and fatigue wear, ensuring the lubricating oil quality is compliant to prevent chain damage.

Monitoring Chain Wear: Regularly check the wear on components of the bulldozer (such as sprocket segments, idlers, track rollers, carrier rollers, and the roller path of the track link) and timely replace severely worn parts to extend the chain’s lifespan.

Preventing Chain Looseness: Conduct regular checks on the tightness of the chains and ensure all connectors are secure to avoid disrupting normal machinery operation and increasing maintenance difficulties.

Considering Environmental Factors: During the design, manufacturing, installation, operation, and maintenance processes, it is crucial to consider the impact of harsh environments on chain performance and implement preventive measures.

Comprehensive Consideration of Fatigue, Corrosion, and Wear: During maintenance, it is important to consider the mutual influence of fatigue, wear, and corrosion, and to take appropriate measures to enhance the durability and reliability of the chain.

Contact Information:

Key Features:

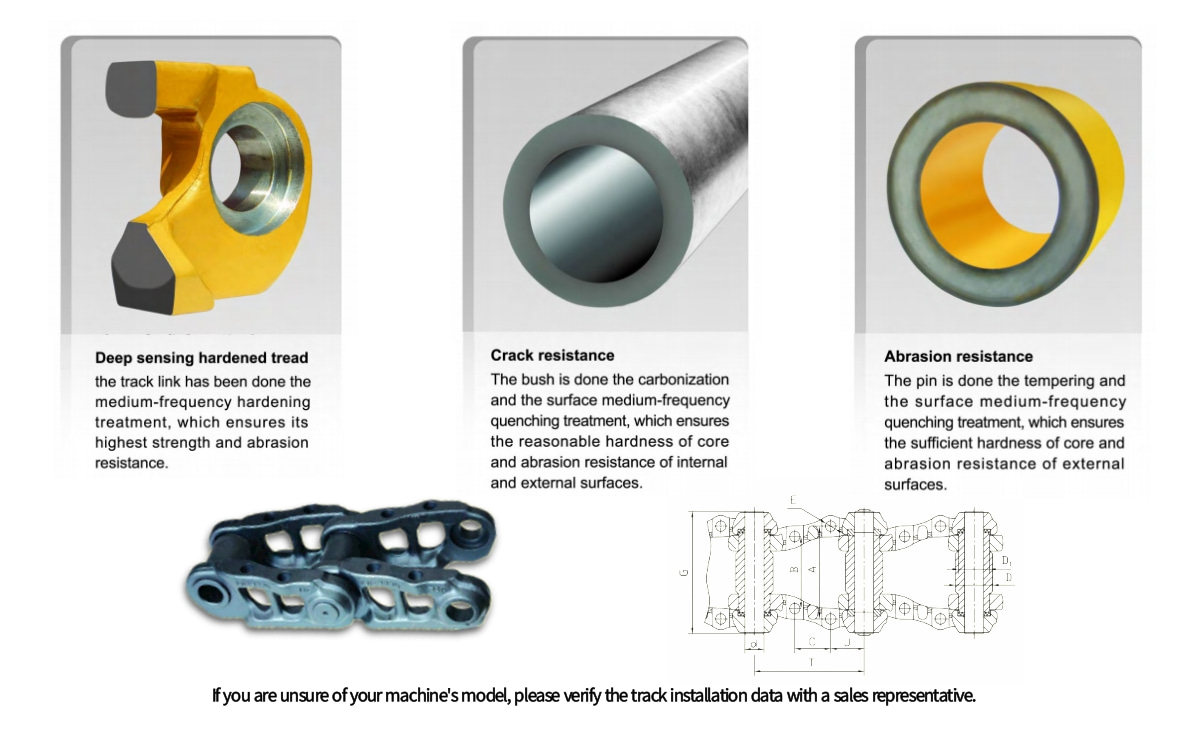

Superior Strength and Durability: Constructed from high-strength alloy steel, our Dozer Chain is engineered to withstand heavy loads and harsh working conditions, ensuring long-lasting performance and reliability.

Excellent Wear Resistance: The Dozer Chain is designed to resist wear and tear, providing extended service life and reducing the need for frequent replacements, thus optimizing equipment uptime and reducing maintenance costs.

Precision Engineering: Each Dozer Chain undergoes precision manufacturing processes, ensuring accurate dimensions, smooth surfaces, and consistent quality, meeting the stringent requirements of heavy-duty applications.

Advanced Heat Treatment: The Dozer Chain is subjected to advanced heat treatment processes, enhancing its hardness and strength to withstand the high stress and friction encountered during bulldozing operations.

Stringent Quality Control: Our Dozer Chain undergoes rigorous quality control measures, including material testing, in-process inspections, and comprehensive quality checks, ensuring that each chain meets the highest standards of performance and reliability.

Why Choose Us

High Cost-Effectiveness: Our Dozer Chain offers exceptional value for money, providing superior strength, durability, and wear resistance at a competitive price point. With our product, you can achieve long-term performance without compromising your budget.

Excellent Pre-Sales and After-Sales Service: We are committed to providing outstanding customer support, offering expert guidance and assistance before and after your purchase. Our team is dedicated to ensuring that you have a seamless experience and receive the support you need to maximize the performance of your equipment.

Fast Shipping: We understand the urgency of your equipment needs. That's why we prioritize prompt order processing and fast shipping, ensuring that your Dozer Chain reaches you in a timely manner, minimizing downtime and keeping your operations running smoothly.

Superior Product Quality: Our Dozer Chain is manufactured to the highest standards, utilizing premium-grade alloy steel and precision engineering to deliver exceptional strength, durability, and wear resistance. Each chain undergoes stringent quality control measures to ensure consistent quality and reliability.

FAQ

Q: What materials are your Dozer Chains made of?

A: Our Dozer Chains are crafted from high-strength alloy steel for exceptional durability and wear resistance.

Q: What sizes are available for your Dozer Chains?

A: We offer a range of sizes to accommodate various bulldozer models and specifications. Custom sizes can also be accommodated upon request.

Q: Can you provide OEM or customized Dozer Chains?

A: Yes, we have the capability to provide OEM and customized Dozer Chains to meet specific requirements and applications.

Q: What is the lead time for orders of Dozer Chains?

A: Our standard lead time for Dozer Chains is 7-10 days, with expedited options available for urgent requirements.

Q: What quality control measures are in place for your Dozer Chains?

A: Our Dozer Chains undergo rigorous quality control processes, including material testing, precision manufacturing, and comprehensive inspections to ensure superior quality and performance.

Q: What is your warranty policy for Dozer Chains?

A: We offer a 1-year warranty on all Dozer Chains, providing peace of mind and assurance of product reliability.

Q: Do you provide technical support for installation and maintenance?

A: Yes, our team offers comprehensive technical support and guidance for the installation, operation, and maintenance of our Dozer Chains.

Part number for dozer chains:

MODEL & PART NOS BERCO NOS LINKS PITCH

D3C 6Y1713 CR4749/39 39L 155

D4D 7K2372 CR2567/40 40L 171

D4E 1V7072 CR3628/36 36L 171

D5 5S0816 CR2823/39,CR5035/ 39L 175

D5B 3P3885 CR3520/39 39L 175

D5B 953 7T4637 CR4264/4040 40L 175

D4H 6Y5407 CR5192/39 39L 171

D5H 6Y5412 CR5202/37 37L 190

D6D 963 9W8843 CR4267/36 36L 203

D6C 225 229 6P6131 CR3176/36,CR5059/ 36L 203

D6H 6Y5417 CR4810A/40 CR6587 40L 203

D6R 6I9670 CR5534/40 40L 203

D7 977K 1S6943 CR1769/41 41L 203

D7G 235B 8S2607 CR2567/38,CR5061 38L 216

973 9W9167 CR4700/40 40L 216

D7H 6Y1141 CR5069/40 40L 216

D8K 2P9492 CR3149/41 41L 228

D8R 8E4518 CR4525/44 44L 216

D9H 8S1731 CR2672/39 39L 260

D10R 2389851 CR6075/44 44L 260

D20-6,7 102-32-00032 KM906/37 37L 135

D31P-18,20 11G-32-00025 KM727/41 41L 154

D61X-12 13G-32-00020 KM2868/46 46L 190

D65-8 141-32-00045 KM953/39 39L 203

D65 144-32-00054 KM951/37 37L 203

D65 141-32-00065 KM951/39 39L 203

D65PX-15 14Y-32-00110 KM3467/45 45L 203

D85SS-2 14U-32-00010 KM2094/42 42L 203

D85-21 154-32-00400 KM1103/39 39L 216

D85EX-15 154-32-00620 KM3904/41 41L 216

D155 175-32-00103 KM325/41 41L 228

D275A-5 17M-32-00400 KM3593/39 39L 260

D355A-5 195-32-00105 KM596/39 39L 260

D375A-5 195-32-00591 KM3599A/40 40L 280

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported