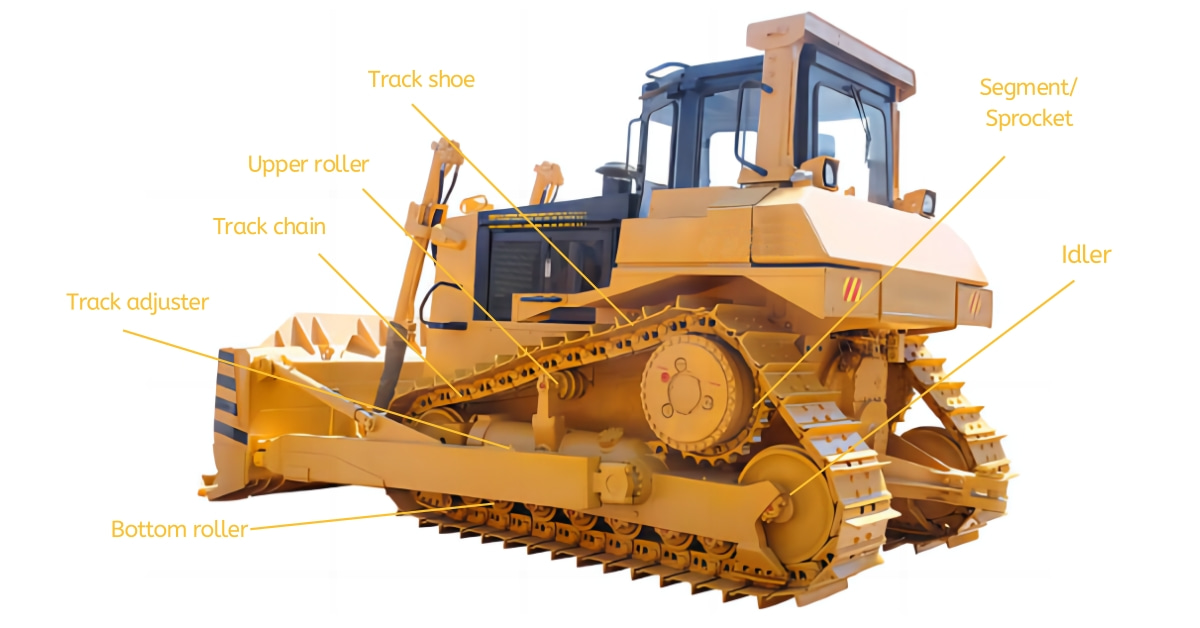

Dozer Undercarriage Parts

Experience unmatched durability and quality with the D85 Bulldozer Upper Roller Fit For Komatsu . Crafted with precision and engineered to perfection, this exceptional product guarantees unmatched longevity even in demanding work environments. Its robust construction and superior materials ensure reliability, allowing you to conquer the toughest terrains with utmost confidence.

| Material | 40SiMnTi/50Mn/35MnB/40MnB/40Mn2 |

| Finish | Smooth |

| Processing | Forging, Casting, Machining, Heat treatment |

| Surface Hardness | HRC48-54,deepth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty time | 2000 hour |

| Delivery Time | Within 15days after payments. |

| MOQ | 2set |

1. Superior Materials: Our D85 Bulldozer Upper Roller Fit For Komatsu is manufactured using premium quality materials. The roller is made from high strength steel, ensuring reliable performance and longevity. The use of such top-notch materials enhances the overall durability and reliability of the product.

2. Advanced Heat Treatment Process: The upper roller undergoes a precisely controlled and rigorous heat treatment process. This ensures that the roller achieves optimal hardness and toughness, enabling it to withstand the demanding conditions of bulldozing operations. The advanced heat treatment guarantees the roller's superior strength and resistance to wear and tear.

3. Stringent Quality Control: At every stage of the production process, stringent quality control measures are implemented to ensure the highest level of product quality. Our skilled technicians perform meticulous inspections to guarantee that each D85 Bulldozer Upper Roller Fit For Komatsu meets the strictest standards. This commitment to quality ensures that customers receive a reliable and consistent product every time.

4. Exceptional Durability: The D85 Bulldozer Upper Roller Fit For Komatsu is known for its exceptional durability. The combination of premium materials, advanced heat treatment, and strict quality control measures result in a roller that can handle heavy loads, harsh terrains, and continuous use. With its outstanding resistance to abrasion and extended lifespan, this upper roller provides exceptional value for money.

| Model | OEM Part No. |

| 8P6256/9P2663 | D8K Dozer Carrier Roller |

| 8E0400 | D8N Dozer Top Roller |

| 141-30-00110 | D50-15~18 Dozer Upper Roller |

| 141-30-00568 | D60-6 Top Carrier Roller |

| 14X-30-00141 | D65EX-12 Carrier Roller |

| 155-30-00233 | D80-18 Carrier Roller |

| 175-30-00515 | D150A-1/D155A-1 Carrier Roller |

| 6S3609 | D3B/D3C Carrier Roller |

| 6K9880/3K7962 | D4 Carrier Roller |

| 6Y3908 | D5H Carrier Roller |

| 6Y1781 | D6H/D6R Carrier Roller |

| 9S3570/5A8374 | D5B/D6B Carrier Roller |

| 3T3206/9S2730 | D6C/D6D Carrier Roller |

| 1P8717/2P3514 | D7F/D7G Carrier Roller |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported