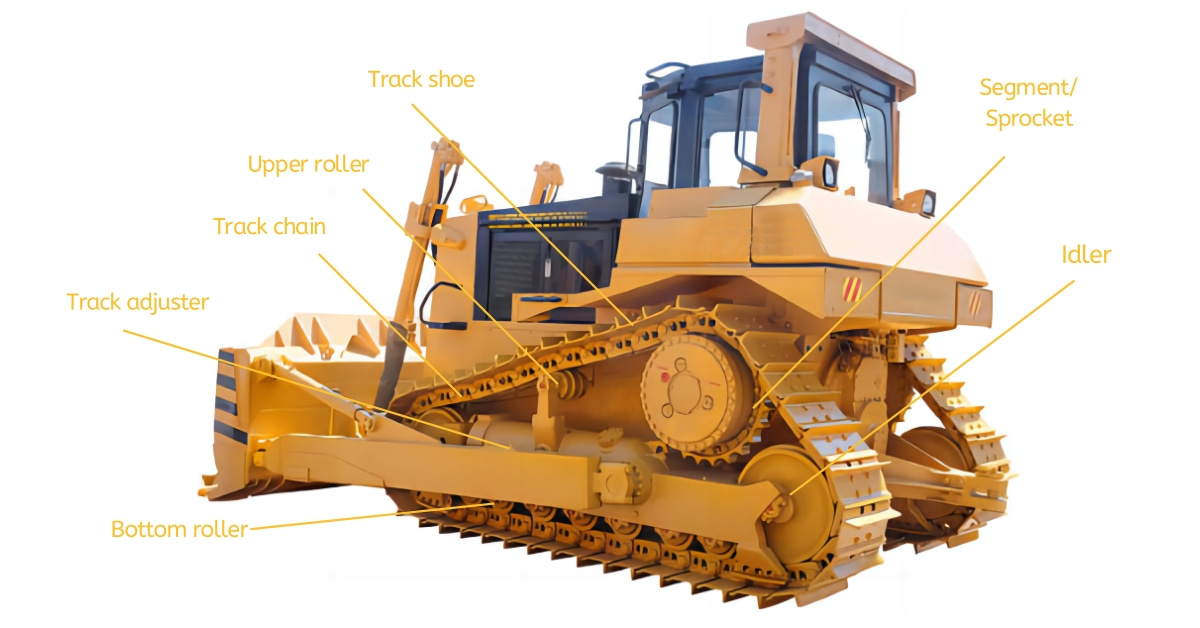

Dozer Undercarriage Parts

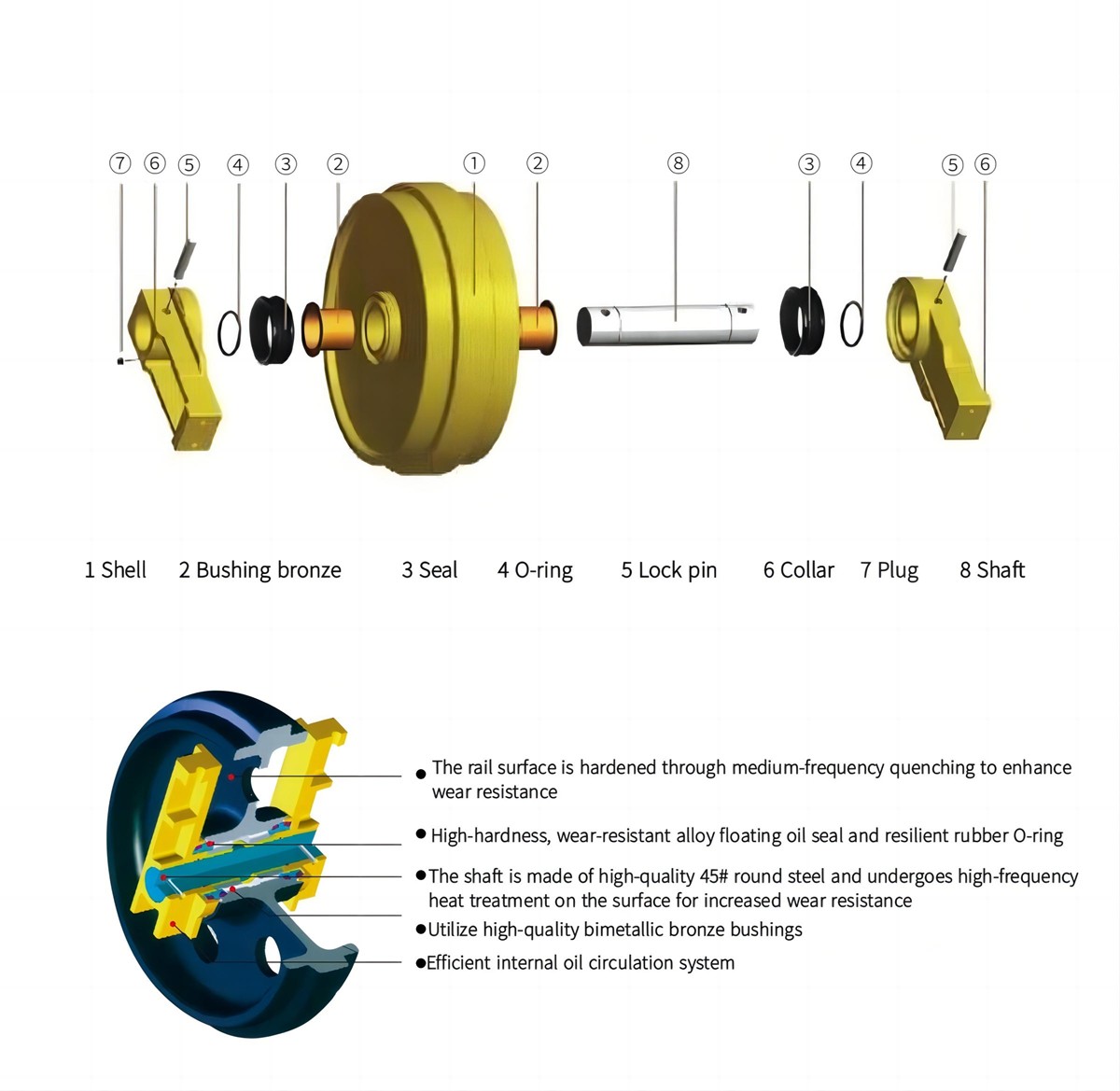

Crafted with utmost precision and engineered to perfection, our D7G/D7F Dozer Front Idler Assembly ensures optimal durability and reliability even under the most challenging work conditions. Upgrade your dozer's stability and maximize its efficiency with this top-notch product.

| Material | 50Mn/40MnB |

| Finish | Smooth |

| Colors | Black or yellow |

| Technique | Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness | HRC48-54,deepth:4mm-10mm |

| Warranty time | 2000 hour |

| MOQ | 2 piece |

| Delivery Time | Within 30 days after payments |

KASU PARTS also manufacturer all of D7G undercarriage parts as below:

D7G Track group P/N 3P0361 BERCO CR3145/38/22

D7G Track chain lubricated chain 38 links pitch 215.90mm P/N 117-1024 3P0629

D7G Track shoes P/N 1M8799 1P9808 2M8876 7M0730

D7G Track bolts and nuts

D7G Track rollers SF single flange P/N 118-1623 124-8250 125-4178 323-5925 3P1520 3P6062 4S9050 4S9051 6T9871 9S0316

D7G Track rollers DF double flange P/N 118-1625 124-8253 125-4179 188-5597 323-5928 3P1521 3P6063 6P9885 6T9867 8S2933 9S0317

D7G Segment P/N 3P0636 3S0351 6T4178 6Y5013 8E4675 8P8174

D7G Carrier rollers P/N 4S8982 4S9691 5M7820 5S3271 7M9489 9M0637 9M0638

Model OEM Part No.

D8N/D8R 9W9989 Front Idler

D9N/D9R 7T2769 Dozer Idler

D10N/D10R 7T0962 Bulldozer ldler

D20/D21 103-30-00120 Idler For Dozer

D30/D31 113-30-00102 ldler For Bulldozer

D50 131-30-00285 Idler Fit For Komatsu Dozer

D65-8 144-30-00038 Idler

D65-12 14X-30-00112 ldler

D85-18 154-30-00293 Idler

D85-21 154-30-00770 Idler

D155A-1 175-30-00575 Idler

D355A-3 195-30-00283 Idler

D3C 9N4173 Idler Fit For CAT Dozer

D4D/D4E 1M8867 Idler Fit For CAT Bulldozer

D4H 190-1534 Idler

D4H 190-1551 Idler

D5 CR3190 Idler

D5H 161-7549 Idler

D6C/D6D 7T4562 ldler

D6H/D6R 2024296 Idler

D6H/D6R 2024304 Idler

D7F/D7G 7T4509 Idler

D8K CR4096 Idler

D8N/D8R 9W9987 Idler

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported