| Material |

40Cr、35MnB |

| Finish |

Smooth |

| Colors |

Black or yellow |

| Processing |

Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness |

HRC52-58,deepth:8mm-12mm |

| Delivery Time |

Within 30 days after payments |

| OEM/ODM Service |

Available |

| MOQ |

1 Set |

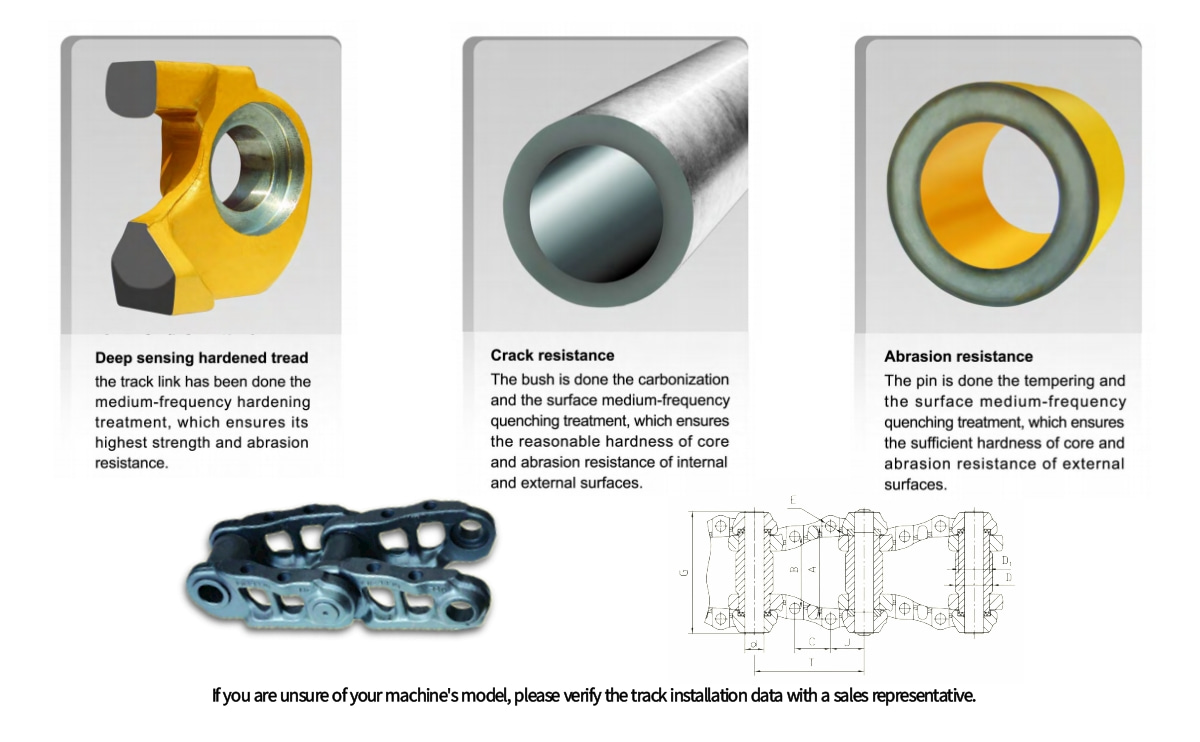

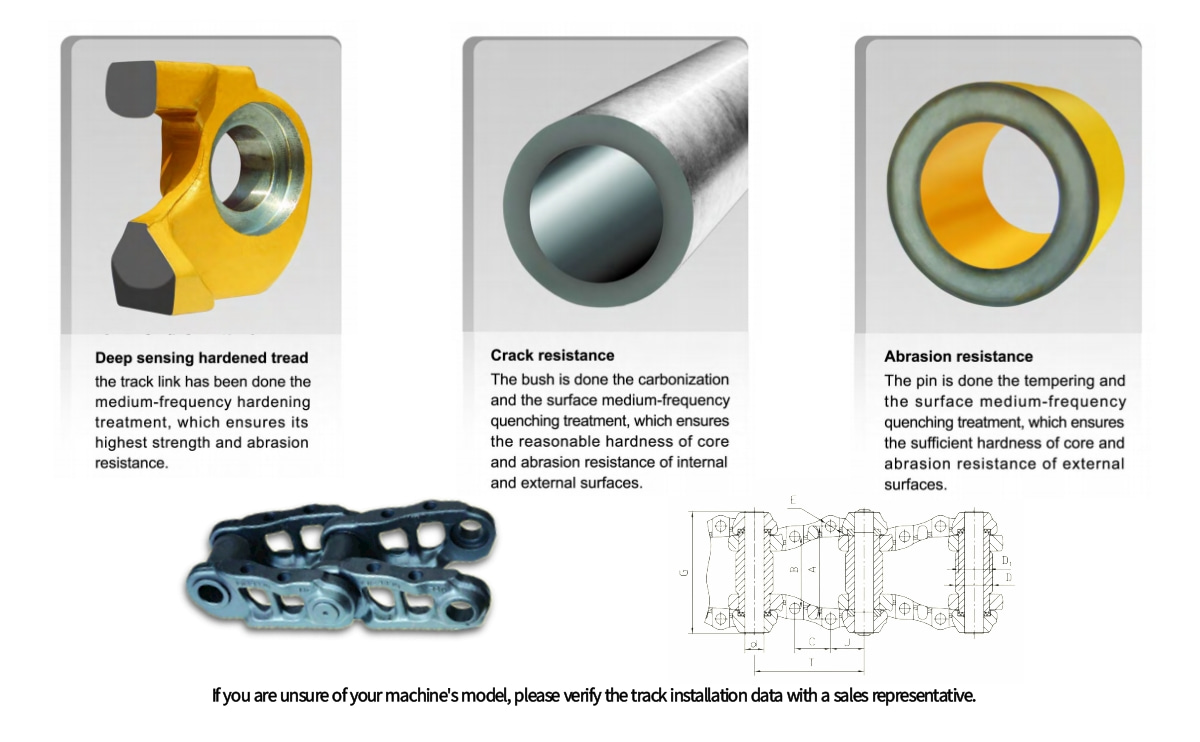

The Salt Track Chain is made up of salt links, which are heat-treated to increase their strength and resistance to wear and tear. The chain is also sealed and lubricated internally, which helps to reduce friction and wear, and prolong the life of the chain. The internal lubrication also means that the chain requires less maintenance compared to dry chains, which need regular external lubrication.

- Product Advantages of D65EX12 Dozer Salt Track Chain:

1. Enhanced Durability: Our D65EX12 Dozer Salt Track Chain is specifically engineered to provide unbeatable durability. The internal lubrication system of this sealed and lubricated track chain effectively reduces friction and wear, consequently prolonging the lifespan of the chain. With our track chain, you can rest assured that it will withstand the test of time, delivering exceptional performance in even the toughest operating conditions.

2. Reduced Maintenance: We understand the importance of minimizing downtime and maximizing productivity. That's why our track chain is designed with reduced maintenance in mind. The internal lubrication system eliminates the need for frequent external lubrication, saving you valuable time and effort. Say goodbye to the hassle of constantly checking and lubricating the chain, and say hello to increased efficiency and productivity.

3. Protection Against External Contamination: Contamination from external elements can severely impact the performance and longevity of a track chain. We have tackled this issue by implementing a meticulously sealed design for our D65EX12 Dozer Salt Track Chain. The sealed construction effectively shields the internal lubrication from harmful external contaminants such as dirt, water, and debris. By preventing their entry, we ensure that your track chain remains free from damage, ensuring its durability and performance are consistently maintained.

- Why Choose Us

1. Superior Material: Our D65EX12 Dozer Salt Track Chain is crafted using premium-grade materials, ensuring exceptional durability and longevity. Made from high-quality alloy steel, it offers excellent resistance to wear, corrosion, and impact, making it ideal for heavy-duty construction and mining applications.

2. Scientific and Rigorous Heat Treatment Process: We employ a highly specialized heat treatment process that guarantees the optimal hardness and strength of our track chains. This advanced technique ensures the ability to withstand extreme working conditions and delivers maximum performance, even under the most demanding environments.

3. Stringent Product Inspection: At our company, quality control is paramount. Every D65EX12 Dozer Salt Track Chain undergoes rigorous inspections and tests to ensure its conformance to stringent industry standards. Our team of experienced professionals meticulously examines each chain to guarantee its flawless performance and reliability.

4. Enhanced Performance and Efficiency: With our D65EX12 Dozer Salt Track Chain, you can achieve enhanced performance and increased efficiency for your heavy machinery operations. Its precise design and construction minimize slippage, reduce friction, and optimize energy transmission, allowing for smoother movement and improved productivity on the job site.

5. Exceptional Customer Service: We pride ourselves on providing exceptional customer service to our clients. Our dedicated team of professionals is committed to understanding your specific needs and requirements, offering prompt assistance and guidance throughout the entire process. We strive to exceed your expectations and ensure your complete satisfaction.

- The following are partial part numbers for bulldozer track chains, for reference.

Model OEM Part No

D3C 6Y1339 Track Chain

D4D 1V4599 Dozer Track Chain

D5 5S0816 Bulldozer Track Chain

D5H 6Y3595 Dozer Track Links

D6D 3P1118 Track Chain For CAT

D6H 6Y3519 Track Chain Assembly

D7G 3P0629 Track Links For CAT Dozer

D8K 9W8938 Track Chain

D20/D21 102-32-00030 Track Chain For Komatsu Dozer

D30/D31 111-32-00033 Track Links Fit For Komatsu Bulldozer

D50 131-32-00064 Track Chain

D60/D65 141-32-00061 Track Chain

D80/D85 154-32-00112 Track Chain

D155 175-32-00119 Track Chain

Network Supported

Network Supported