Dozer Undercarriage Parts

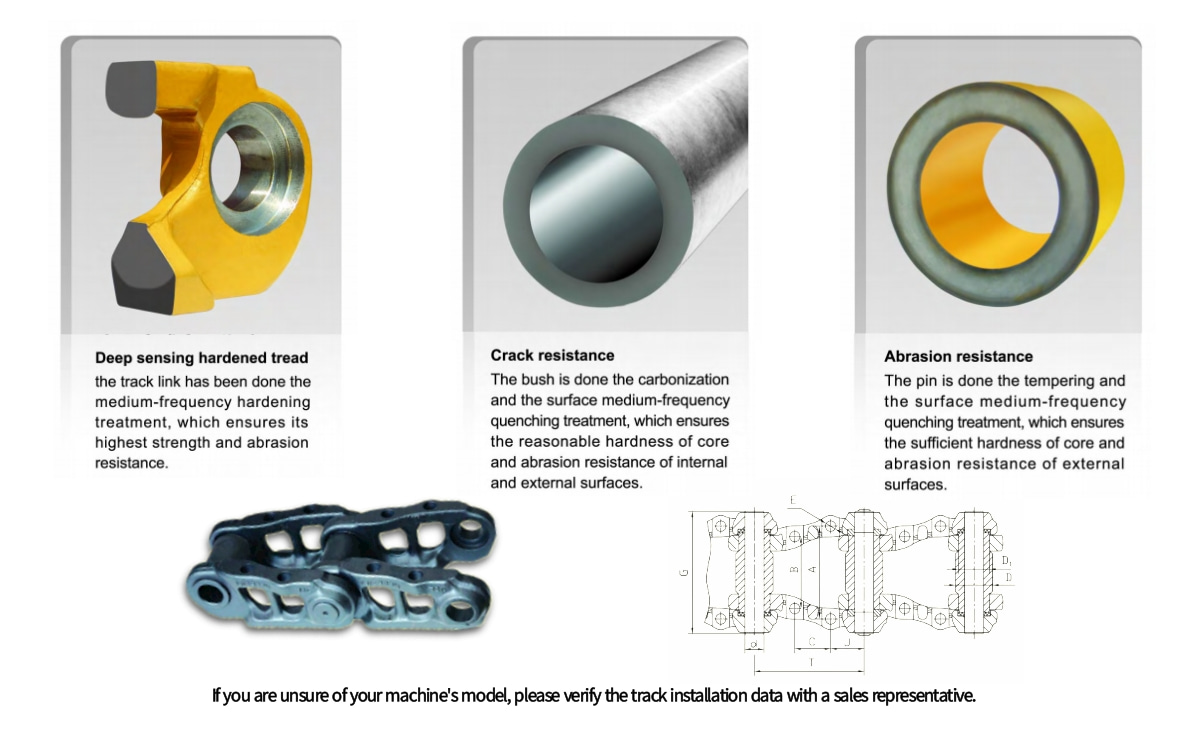

Solid design of track links bulldozer enables wear resistance and stress resistance for long time,The highly finished and deeply quenched chain link, pin sleeve and bush are stronger in wear resistance.

1. Unparalleled Material Excellence: Crafted using top-grade materials, our D155 Track Link Bulldozer ensures durability and resilience even in the most challenging environments. Its robust construction guarantees longevity and the ability to withstand heavy-duty operations.

2. Exquisite Manufacturing Techniques: Meticulously engineered with precision and attention to detail, this bulldozer exemplifies exceptional artistry in its manufacturing process. Each component is carefully crafted, ensuring seamless integration and optimal performance.

3. Rigorous Heat Treatment Process: Our D155 Track Link Bulldozer undergoes a stringent heat treatment process that enhances its strength and toughness. This critical step ensures that each track link can endure high pressure, providing unparalleled reliability and stability.

4. Stringent Quality Inspection: We take no shortcuts when it comes to quality control. Before leaving our facility, every D155 Track Link Bulldozer undergoes a comprehensive quality inspection process. This includes rigorous testing to ascertain performance, functionality, and consistency, guaranteeing the highest standards and customer satisfaction.

5. Enhanced Productivity: Designed with the utmost efficiency in mind, our bulldozer exhibits extraordinary power, precision, and maneuverability. Its cutting-edge technology optimizes productivity, allowing for seamless operation and maximizing work efficiency on diverse terrains.

Model OEM Part No

D3C 6Y1339 Dozer Track Chain

D4D 1V4599 Dozer Track Link

D5 5S0816 Track Chain For CAT Dozer

D5H 6Y3595 Track Link For CAT Bulldozer

D6D 3P1118 Track Chain

D6H 6Y3519 Track Chain

D7G 3P0629 Track Chain

D8K 9W8938 Track Chain

D20/D21 102-32-00030 Track Chain For Komatsu Dozer

D30/D31 111-32-00033 Track Link For Komatsu Dozer

D50 131-32-00064 Track Chain

D60/D65 141-32-00061 Track Chain

D80/D85 154-32-00112 Track Chain

D155 175-32-00119 Track Chain

Q: What materials are used in the construction of the D155 track link bulldozer?

A: The D155 track link bulldozer is constructed using high-quality, high-strength steel materials to ensure durability and reliability in heavy-duty applications.

Q: What kind of processing techniques are utilized in manufacturing this bulldozer?

A: Advanced processing techniques, including precision engineering and cutting-edge manufacturing processes, are employed to ensure the superior quality and performance of the D155 track link bulldozer.

Q: Can you provide details about the heat treatment process used in the production of this bulldozer?

A: The D155 track link bulldozer undergoes a strict heat treatment process, enhancing its toughness and wear resistance, thus ensuring its ability to withstand demanding working conditions.

Q: How is the quality of the D155 track link bulldozer ensured?

A: Rigorous quality inspection procedures are implemented throughout the manufacturing process to guarantee the highest standards of reliability and performance for the D155 track link bulldozer.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported