Dozer Undercarriage Parts

This assembly is composed of a reliable track chain, sturdy track shoes, and secure track bolts and nuts. Offering superior quality and unparalleled durability, our D10N D10R D10T Track Chain Assembly 7T0723 Fit For Caterpillar is the epitome of excellence, destined to withstand the test time.

D10N D10R D10T Dozer Track Chain Assembly 7T0723 Fit For Caterpillar - Sealed & Lubricated

Use Track Bolt: CR5167,7T1000,D01100N0N15,2769128,V7T1000

Use Track Nut: CR3835,5P8221,D0110000N17,7373330,790202814,2764645,043460,3528043460,3650440,V5P8221

Use Track Chian: CR6075/44,CR6100/44,6Y2059,6Y8189,8E7928,G01100N1M00044,G01100N1S00044

Use Track Shoe: CR5040/24, 7T0724, 9W1867

Compatible with D10N D10R D10T D10T2

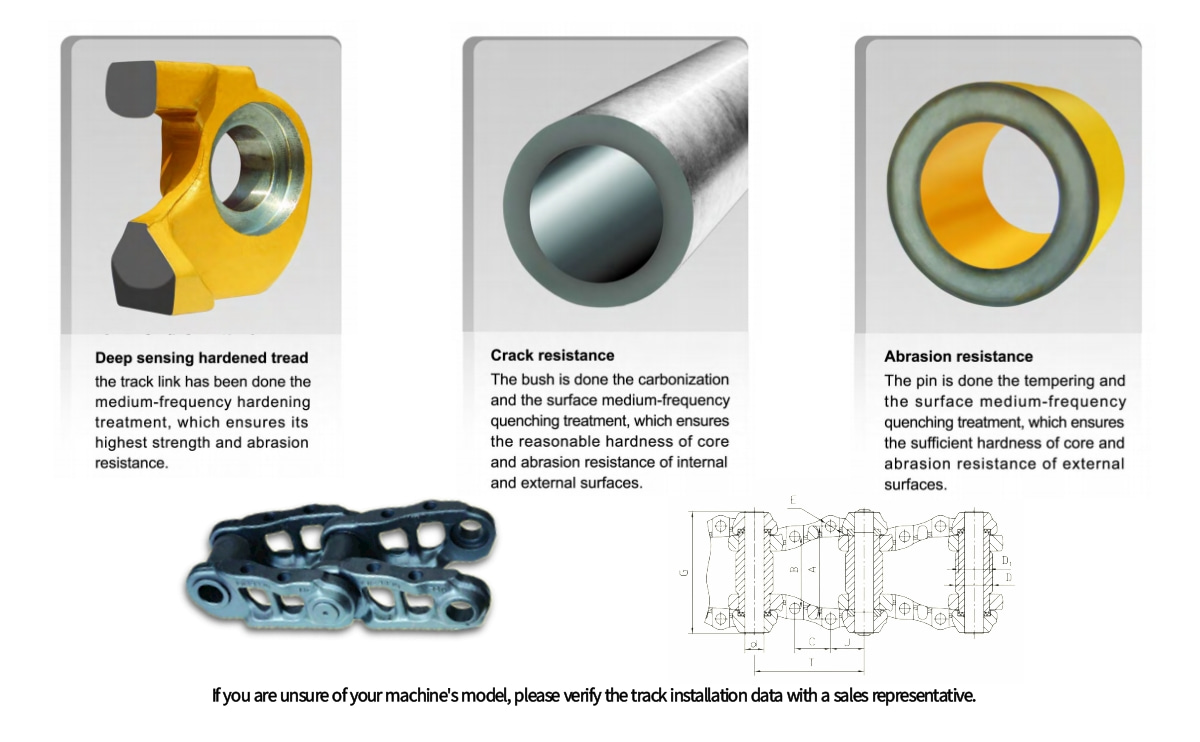

We are a professional manufacturer of dozer undercarriage parts, focusing on the careful selection of product materials and strict control of the production process to ensure that the quality of the products we produce is stable and reliable. The Track Chain is made of loose links, shafts, O-rings, bi-metallic bushing bronze, and seal groups. It is produced through processes such as casting or forging, machining, heat treatment, and assembly.

To correctly identify signs of excessive wear on the track chain assembly of the CAT D10N bulldozer, you can refer to the following points:

Use the CTWS Remote Monitoring System: The CTWS (Cat Track Wear Sensor) is an advanced monitoring technology that can wirelessly transmit real-time track wear information. This system automatically checks the wear condition of the track links while the machine is operating and sends notifications when specific alarm thresholds are reached. For example, it will alert you when wear reaches 40%, indicating that the bushings may rotate; at 70%, it will prompt you to measure and order replacement parts; and at 100%, it indicates that immediate replacement is necessary.

Observe the Condition of the Track Shoes and Link Components: If the track shoes are bent or cracked, or if the links have exceeded the lifespan of the track shoes, it is advisable to use extreme-duty track shoes. These extreme-duty track shoes have higher resistance to bending and cracking and can withstand more abrasive materials.

Check Components such as the Track Tensioning Device and Idler Wheels: The wear condition of components such as the track tensioning device, idlers, track rollers should also be regularly inspected and maintained. Damage to these components can affect the normal operation of the entire track system, accelerating track wear.

Pay Attention to Lubrication: The design of sealed lubricated tracks (SALT) can reduce friction between internal pins and bushings, thereby extending service life and reducing maintenance costs. Therefore, ensuring that the lubrication system is functioning properly is one of the important measures to prevent wear.

Manual Inspection and Adjustment: In addition to relying on the CTWS system, regular manual inspections and adjustments are also necessary. For example, adjusting the track tension under different working conditions can help avoid additional wear caused by improper tension.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported