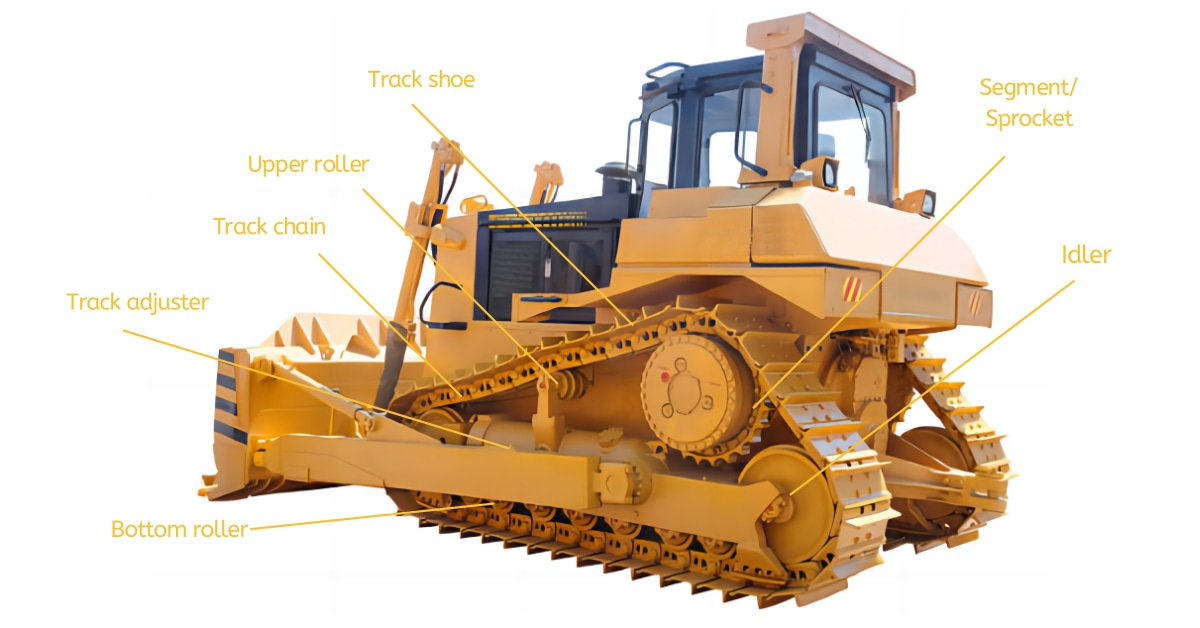

Dozer Undercarriage Parts

Crafted with meticulous precision, our undercarriage components empower your machinery with unmatched performance and durability in the toughest environments. From rugged terrains to challenging work conditions, our innovative undercarriage technology ensures maximum productivity, efficiency, and longevity. Trust our Undercarriage Fit For Caterpillar products to elevate your equipment's capabilities and confidently navigate any job site with unparalleled precision and resilience.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported