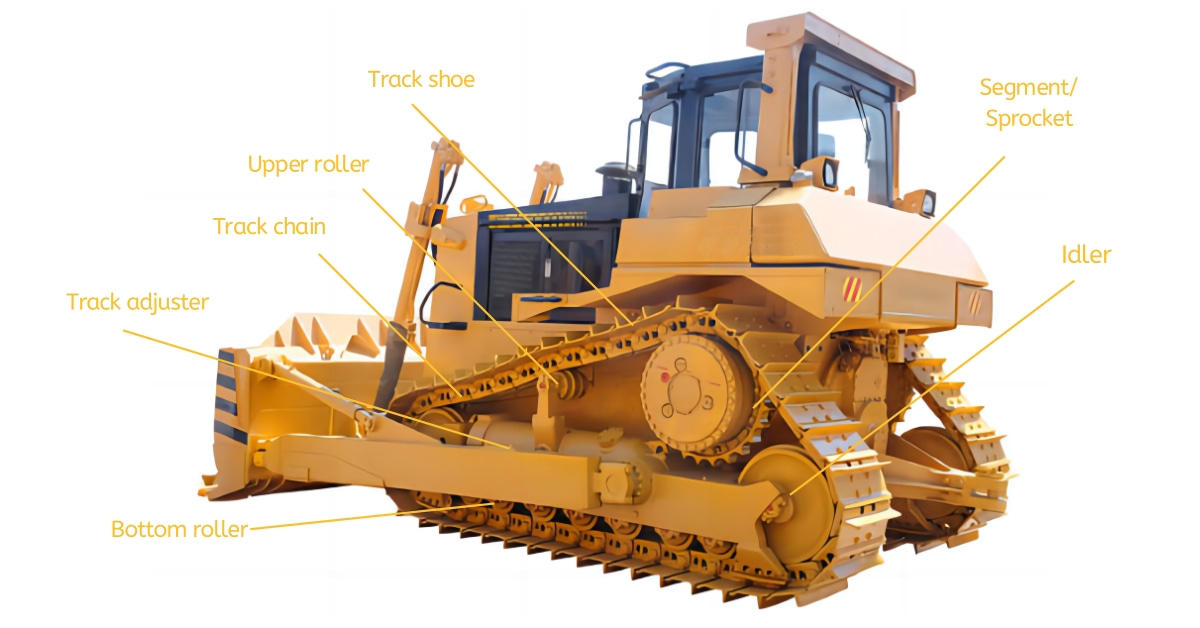

Dozer Undercarriage Parts

Boasting exceptional material quality and long-lasting durability, our Top Carrier Roller Fit For CAT stands as a testament to unparalleled excellence in construction equipment. Crafted with the utmost precision, this product showcases the highest standards of engineering, enabling it to withstand even the harshest operating conditions.

| Material | 40SiMnTi/50Mn/35MnB/40MnB/40Mn2 |

| Finish | Smooth |

| Processing | Forging, Casting, Machining, Heat treatment |

| Surface Hardness | HRC48-54,deepth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty time | 2000 hour |

| Delivery Time | Within 15days after payments. |

| MOQ | 2set |

Firstly, our top carrier roller undergoes a rigorous heat treatment process that enhances its hardness and durability. The heat treatment process we use ensures that the roller can withstand heavy loads and extreme temperatures, making it ideal for use in tough working conditions.

Secondly, we carefully select high-quality materials for our top carrier roller. We use only the best materials available to ensure that the roller is both strong and reliable. Our rigorous material selection process guarantees that our top carrier roller meets the highest industry standards.

our factory has stringent quality control procedures in place to ensure that our top carrier roller meets or exceeds customer expectations. We conduct thorough testing and inspection throughout the production process to ensure that the roller is of the highest quality and meets all relevant safety and performance standards.

| Model | OEM Part No. |

| 8P6256/9P2663 | D8K Carrier Roller |

| 8E0400 | D8N Carrier Roller |

| 141-30-00110 | D50-15~18 Carrier Roller |

| 141-30-00568 | D60-6 Carrier Roller |

| 14X-30-00141 | D65EX-12 Carrier Roller |

| 155-30-00233 | D80-18 Carrier Roller |

| 175-30-00515 | D150A-1/D155A-1 Carrier Roller |

| 6S3609 | D3B/D3C Carrier Roller |

| 6K9880/3K7962 | D4 Carrier Roller |

| 6Y3908 | D5H Carrier Roller |

| 6Y1781 | D6H/D6R Carrier Roller |

| 9S3570/5A8374 | D5B/D6B Carrier Roller |

| 3T3206/9S2730 | D6C/D6D Carrier Roller |

| 1P8717/2P3514 | D7F/D7G Carrier Roller |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported