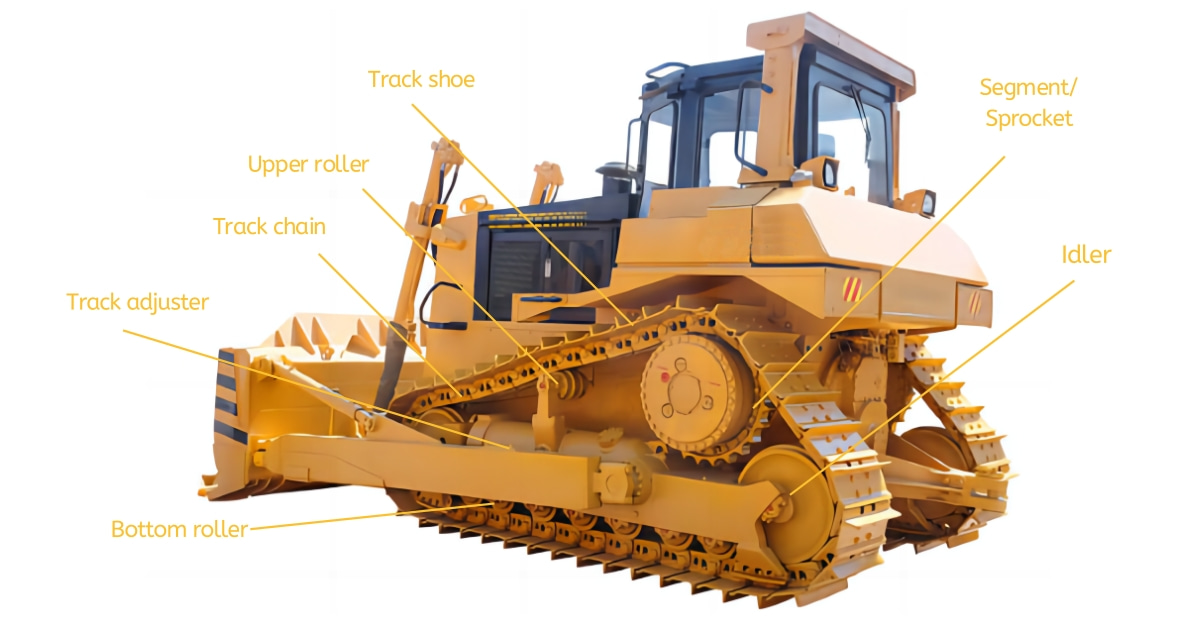

Dozer Undercarriage Parts

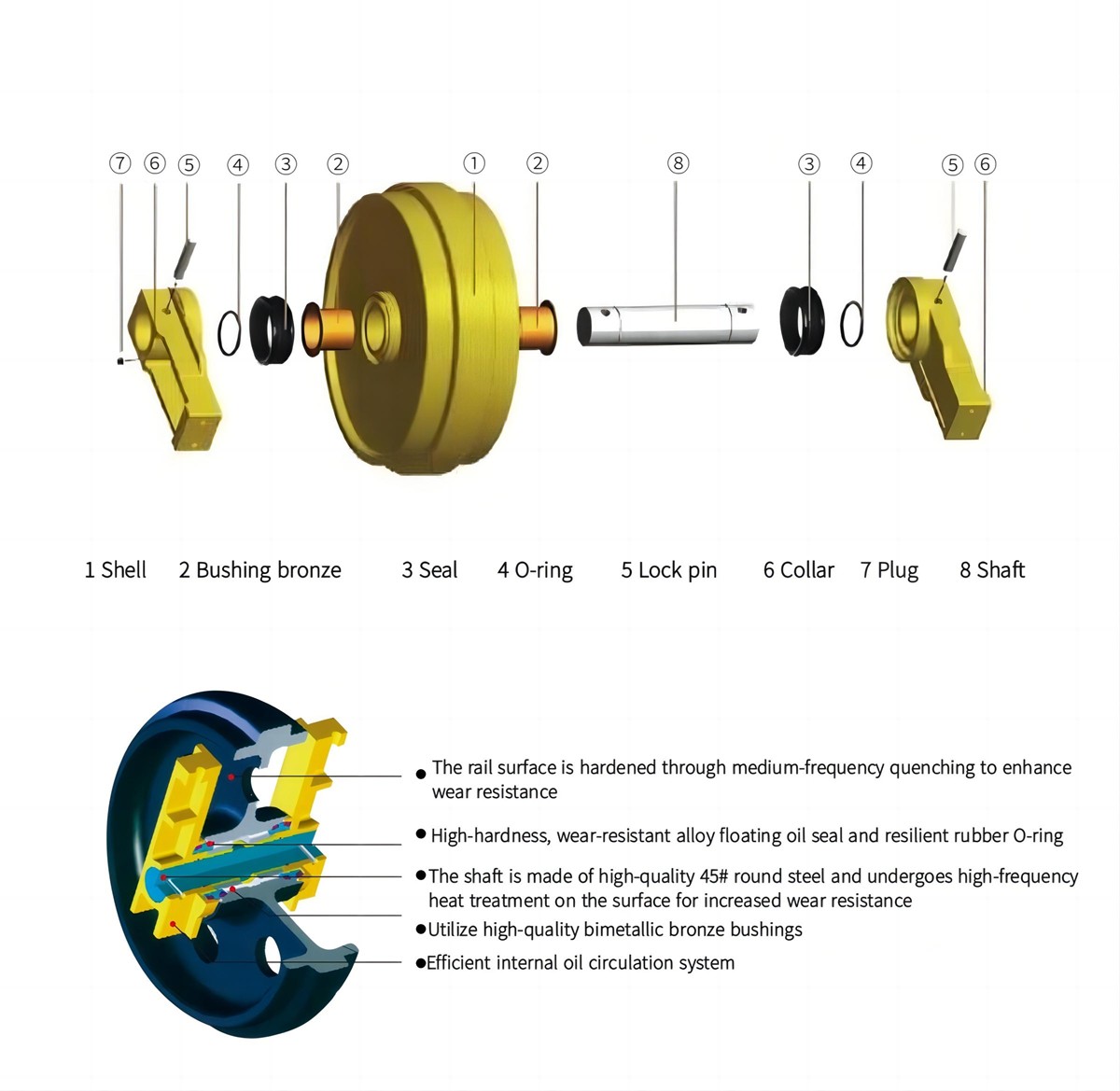

The Dozer Parts D8N Idler Fit For CAT we offer is a vital component for maintaining optimal performance of your CAT Dozer. Crafted with precision engineering and premium quality materials, this idler ensures enhanced durability and longevity, enabling smooth and efficient operation in the most demanding working conditions. Experience superior functionality and reliability with this essential Dozer Parts D8N Idler that perfectly combines professional craftsmanship and exceptional performance.

| Material | 50Mn/40MnB |

| Finish | Smooth |

| Colors | Black or yellow |

| Technique | Forging, Casting, Machining, Heat treatment Quenching |

| Surface Hardness | HRC48-54,deepth:4mm-10mm |

| Warranty time | 2000 hour |

| MOQ | 2 piece |

| Delivery Time | Within 30 days after payments |

KASU PARTS also product the D8N dozer undercarriage parts as below:

D8N Track Group (Assembly track link with shoes) P/N 8E7700 9W3319

D8N Track lubricated link assembly 44 links Pitch 215.90mm P/N 272-6009 6Y1136 8E4518 9W3317

D8N Track SINGLE GROUSER SHOES P/N 7T2750 9P2657

D8N Track bolts 6V1723 and track nuts 7G6442 for track shoes P/N

D8N Bottom rollers SF Single Flange P/N 100-12792 196-9947 246-0775 7T9188 9W8705

D8N Bottom rollers DF Double Flange P/N 132-7929 196-9946 246-0779 7T9193 9W8706

D8N Top Rollers P/N 8E0400

D8N Segment Assy P/N 9P1898 9W0074

D8N Segment P/N 114-6413 162-9534 173-0947 173-0948 314-5462 6T3197 6Y2354 7T9773

D8N Segment bolt P/N 5P4130 5P7665 and nuts P/N 7H3608

Model OEM Part No.

D8N/D8R 9W9989 Front Idler

D9N/D9R 7T2769 Dozer Idler

D10N/D10R 7T0962 Bulldozer ldler

D20/D21 103-30-00120 Idler For Dozer

D30/D31 113-30-00102 ldler For Bulldozer

D50 131-30-00285 Idler Fit For Komatsu Dozer

D65-8 144-30-00038 Idler

D65-12 14X-30-00112 ldler

D85-18 154-30-00293 Idler

D85-21 154-30-00770 Idler

D155A-1 175-30-00575 Idler

D355A-3 195-30-00283 Idler

D3C 9N4173 Idler Fit For CAT Dozer

D4D/D4E 1M8867 Idler Fit For CAT Bulldozer

D4H 190-1534 Idler

D4H 190-1551 Idler

D5 CR3190 Idler

D5H 161-7549 Idler

D6C/D6D 7T4562 ldler

D6H/D6R 2024296 Idler

D6H/D6R 2024304 Idler

D7F/D7G 7T4509 Idler

D8K CR4096 Idler

D8N/D8R 9W9987 Idler

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported