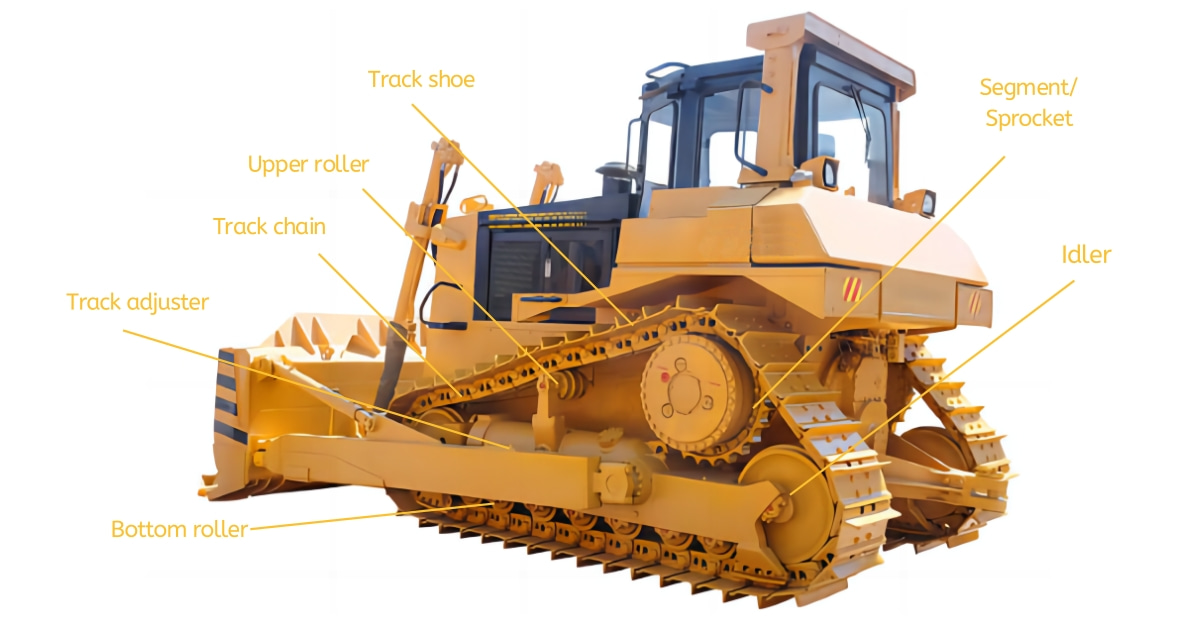

Dozer Undercarriage Parts

Elevate your dozer's undercarriage performance with our Carrier Rollers. Meticulously crafted using top-tier materials and advanced techniques, these rollers guarantee durability and seamless operation in demanding work conditions. Trust in precision engineering for extended undercarriage longevity.

The importance of daily maintenance for Carrier Roller Dozer is reflected in several key aspects:

Enhancing Equipment Reliability and Safety: As a crucial component of the bulldozer's mobility system, the wear and tear of carrier rollers directly impact the normal operation and safety of the bulldozer. The contact area between the track rollers and the track chain links is a common wear point. If these worn areas are not promptly maintained and repaired, they can lead to more severe mechanical failures and even safety incidents.

Extending Equipment Lifespan: Regular inspection, lubrication, and replacement of worn parts for carrier rollers can effectively reduce the rate of wear, thereby extending the lifespan of the rollers and the entire mobility system. Proper maintenance can increase the lifespan of carrier rollers by approximately 5,000 hours, which not only enhances work efficiency but also reduces long-term operational costs.

Reducing Repair Costs and Downtime: Frequent breakdowns and repairs can escalate operational costs for businesses and potentially delay production schedules. By implementing effective daily maintenance, the occurrence of failures can be prevented, minimizing downtime caused by repairs and ensuring continuity and efficiency in production.

Improving Work Efficiency and Quality: Maintaining carrier rollers in good condition ensures the stability and maneuverability of bulldozers across various complex terrains, which is crucial for enhancing construction quality and efficiency.

----KeyFeatures:

1. Uncompromising Durability: Constructed using premium-grade materials, our Carrier Roller Dozer boasts exceptional strength and durability. Its robust framework withstands the harshest conditions, ensuring a long-lasting performance that stands the test of time.

2. Precision Engineering: Every aspect of our Carrier Roller Dozer undergoes meticulous engineering, resulting in flawless functionality. From the precisely calibrated dimensions to the seamless integration of components, each roller delivers unrivaled performance and smooth operation.

3. Advanced Heat Treatment: To elevate the performance further, our Carrier Roller Dozer undergoes a state-of-the-art heat treatment process. This enhances its hardness, toughness, and wear resistance, ensuring optimal performance even in the most demanding environments.

4. Exemplary Quality Control: We understand the significance of uncompromising quality. Each and every Carrier Roller Dozer undergoes rigorous quality inspections, adhering to the strictest industry standards. Our commitment to excellence guarantees that you receive a product that sets the benchmark for quality.

5. Improved Efficiency: With its innovative design, our Carrier Roller Dozer optimizes efficiency and productivity. Its smooth rotation and low friction attributes reduce energy consumption, enhancing overall machine efficiency and minimizing downtime.

----Why Choose Us

1. Unparalleled Customer Service:

We prioritize our customers and strive to provide a delightful experience from the moment you contact us. Our dedicated team of professionals is always ready to assist you with any queries or concerns. We take pride in offering personalized attention and are committed to resolving any issues promptly, ensuring complete customer satisfaction.

2. Extensive Range of Products:

With an extensive range of Carrier Roller Dozers, we cater to a diverse set of requirements. Whether you need a specific model or require customizations, we have you covered. Our comprehensive selection guarantees that you will find the perfect fit for your project, no matter the scale or complexity.

3. Superior Quality:

Each Carrier Roller Dozer we offer is crafted with precision and adheres to stringent quality standards. We collaborate with renowned manufacturers who continuously innovate and incorporate cutting-edge technology, ensuring that our products deliver exceptional performance, durability, and reliability.

4. Timely Delivery:

We understand the importance of timely delivery in the fast-paced world of business. Our highly efficient logistics network enables us to dispatch your order promptly and accurately. Rest assured, your Carrier Roller Dozer will reach you within the committed timeframe, allowing you to keep your projects on schedule.

5. Expert Guidance:

We value relationships and believe in providing the highest level of professional expertise. Our team consists of industry experts who possess in-depth knowledge of Carrier Roller Dozers. We are here to guide you through the selection process, understand your specific requirements, and offer relevant insights to make an informed decision.

----FAQ

Q: What materials are utilized in the manufacturing of your Carrier Roller Dozer?

A: Our Carrier Roller Dozer is meticulously crafted using top-grade steel alloys, guaranteeing exceptional durability and resistance to wear.

Q: Are your Carrier Roller Dozers compatible with various machine models?

A: Without a doubt! Our extensive range of Carrier Roller Dozers is designed to seamlessly fit diverse machine models. Simply provide us with your specific machine details, and we will find the perfect match for you.

Q: How do you ensure the impeccable quality of your Carrier Roller Dozers?

A: To ensure unrivaled quality, our Carrier Roller Dozers go through rigorous examinations, including meticulous material inspections, precision machining, and comprehensive testing, all in accordance with, if not surpassing, industry standards.

Q: Do you offer support for OEM or custom orders?

A: Absolutely! We wholeheartedly support OEM arrangements and eagerly welcome custom orders. Share your distinct specifications, and we will tailor our Carrier Roller Dozers to meet your unique requirements perfectly.

Q: What is the estimated turnaround time for orders?

A: Our primary objective is prompt order processing. Upon receipt of payment, expect your Carrier Roller Dozers to be expedited for shipping within a week, granted the product is in stock.

Q: How do you handle the shipping and logistics process?

A: We provide utmost flexibility when it comes to shipping options. You can choose between renowned carriers such as DHL, FedEx, UPS, or opt for delivery by Air/Sea. Additionally, if you have an established agent in China, we are more than willing to coordinate with them according to your preference.

Q: Does your Carrier Roller Dozer come with a warranty?

A: Certainly! We proudly offer a comprehensive 1-year warranty for our Carrier Roller Dozers. In the rare event that any issues arise, our dedicated after-sales support team will be readily available to lend their assistance.

Q: Can I receive guidance regarding installation and maintenance?

A: Absolutely! We are committed to ensuring your utmost satisfaction with our Carrier Roller Dozers. As such, we provide detailed guidance on both the installation and maintenance processes, ensuring that you extract maximum performance and longevity from your investment.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported