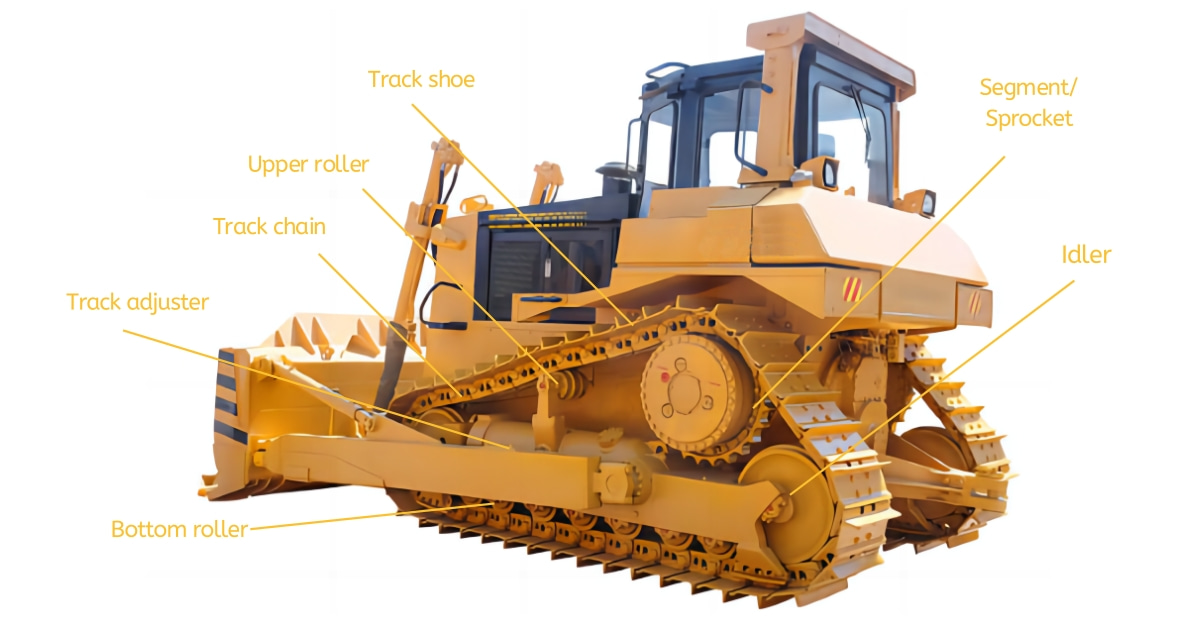

Dozer Undercarriage Parts

Constructed with durability and precision in mind, our Bulldozer Undercarriage is the epitome of excellence. Engineered to facilitate seamless operation, it boasts a robust structure that ensures optimum efficiency and longevity. With exceptional traction and a rugged design, our Bulldozer Undercarriage guarantees superior performance even in the most challenging terrains.

1. Rich Production Experience:

With years of experience in the industry, our team has gained valuable expertise in manufacturing bulldozer undercarriage components. We understand the specific requirements and challenges that come with this field. Our extensive knowledge ensures that we can deliver products of the highest quality that meet the rigorous demands of heavy-duty machinery.

2. Diverse Product Line:

Our range of bulldozer undercarriage parts covers a wide variety of models and specifications. From track chains and rollers to sprockets and idlers, we offer comprehensive solutions to cater to different equipment needs. Our commitment to staying updated with advancing technologies allows us to provide innovative options that enhance performance and longevity.

3. Professional After-Sales Service:

We thrive on customer satisfaction and believe that our commitment extends beyond the initial sale. In the unlikely event of any issues or concerns, our dedicated after-sales team is readily available to provide prompt assistance and solutions. We understand the impact of downtime on productivity, and our aim is to minimize disruptions by offering timely support, spare parts, and guidance.

4. Timely Delivery:

We recognize that time is of the essence in the world of construction and heavy machinery. Our streamlined production processes and efficient logistics enable us to ensure timely delivery of your bulldozer undercarriage components. Whether you require replacements or new additions to your equipment, we prioritize swift and accurate shipments, minimizing waiting times and allowing you to keep your operations running smoothly.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported