Dozer Undercarriage Parts

This Bulldozer Track Link Assembly Fit For Caterpillar D7F crafted assembly ensures smooth maneuverability and exceptional traction in the most challenging terrains. Designed to exceed industry standards, it guarantees seamless compatibility with Caterpillar D7F, making it the ultimate choice for enhanced productivity efficiency.

Bulldozer Track Link Assembly Fit For Caterpillar D7F includes the following components:

D7F track links:

BERCO CR2576/38, CR2576A/38

CATERPILLAR 1M3671, 2S1753, 8S2607

ITM E01730D0M00038, E01730D1M00038

LIEBHERR 5800074

D7F track shoes:

BERCO CR2086/22, CR2086A/22, CR2086B/22

CATERPILLAR 1M8799, 1P9808, 2M8876, 7M0730

ITM Z01071A0N0559V

KOMATSU 154-32-11610

D7F track bolt and track nuts:

BAUER 62658

BERCO CR2221

CATERPILLAR 1S1859, 1S8804, 7H3598

ITM D01070P0N15

JOHN DEERE T50724, T59205

KOMATSU 150-32-21321, 154-32-31320

LIEBHERR 4097517, 7001690

VOLVO 18012640

The lifespan of the Bulldozer Track Link Assembly typically depends on various factors, including the material of the track, working environment, usage frequency, and maintenance. According to different statistical analyses, the lifespan of bulldozer tracks can vary significantly. For example, the average lifespan of aftermarket tracks is about3,154 hours, while the original factory tracks typically last between4,500 and8,000 hours.

Factors that affect the lifespan of the Bulldozer Track Link Assembly include:

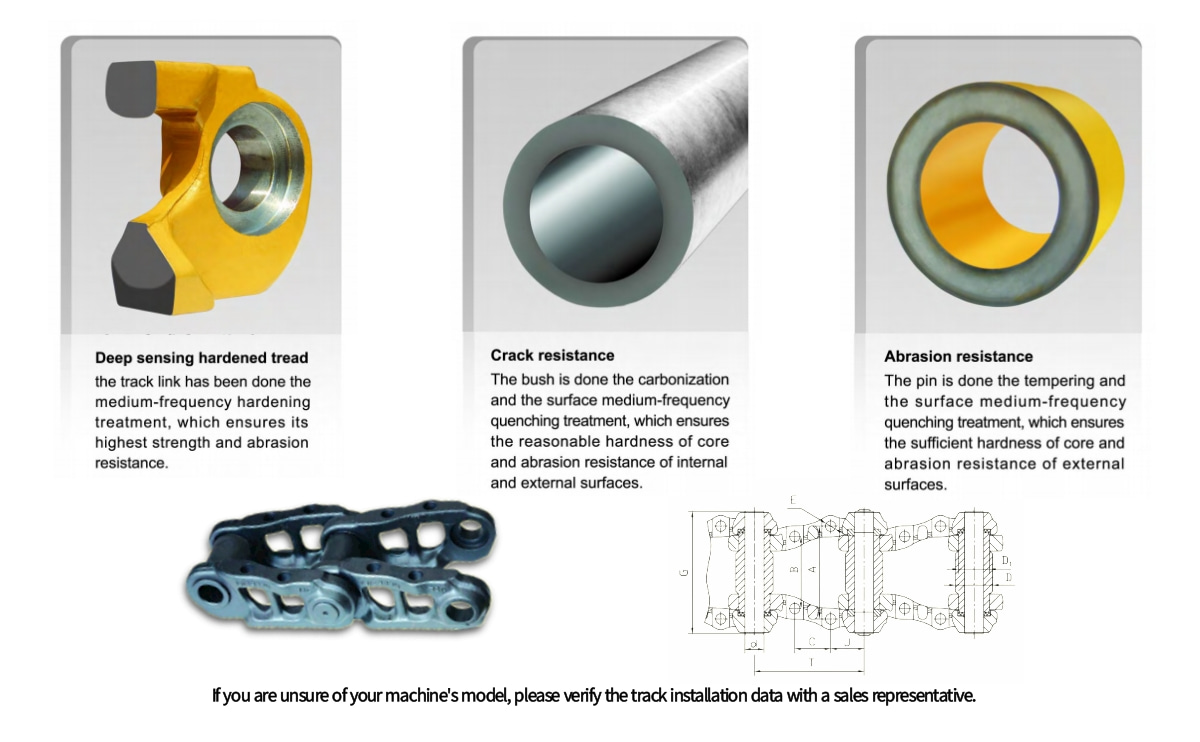

Track Material: The material of the Bulldozer Track Link Assembly directly impacts its wear resistance and fatigue resistance. Using deep-hardened steel can enhance the track's hardness and fatigue resistance, thus extending its lifespan.

Working Environment: The Bulldozer Track Link Assembly's load-bearing capacity and lifespan can be affected by operating in high or low-temperature environments. In high-temperature environments, the load-bearing capacity of the track should be reduced, while low-temperature environments may require the use of special materials.

Lubrication: The lubrication condition of the Bulldozer Track Link Assembly is crucial for its lifespan. Proper lubrication can reduce wear and prolong the life of the track.

Maintenance: Regular inspection and maintenance of the Bulldozer Track Link Assemblies are key to extending its lifespan. This includes measuring and adjusting the track's elongation, controlling the track's tension, and timely replacing any problematic components.

Usage Frequency: The higher the frequency of Bulldozer Track Link Assembly use, the greater the degree of wear and fatigue, which can shorten its lifespan.

Tension: The tension of the Bulldozer Track Link Assembly directly affects the pressure, sliding, and friction between parts of the bulldozer's travel mechanism. Both excessive tightness and looseness can lead to excessive wear or detachment of the track.

Load Conditions: If the track bears excessive loads, it may break due to fatigue; its lifespan depends on the magnitude and frequency of these overloads.

Storage Conditions: Bulldozer Track Link Assemblies should be stored in a dry, cool place to prevent dust and other impurities from entering the track and reducing the effectiveness of the lubrication.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported