Dozer Undercarriage Parts

Our Bulldozer Front Idler D8N D8R D8T 2Y7339 CR4155 Fit For Caterpillar undergoes rigorous quality control processes to guarantee performance and longevity.

Bulldozer Front Idler D8N D8R D8T 2Y7339 CR4155 Fit For Caterpillar

Product Name: Bulldozer Front Idler

Compatibility: Caterpillar D8N, D8R, D8T, 578

Part Numbers: BERCO CR4155, CR4530, CATERPILLAR 1111730, 2Y7339, 5Y0742, 6Y0557, 7T2050 , 7T9461, 9P0209 , 9W9989

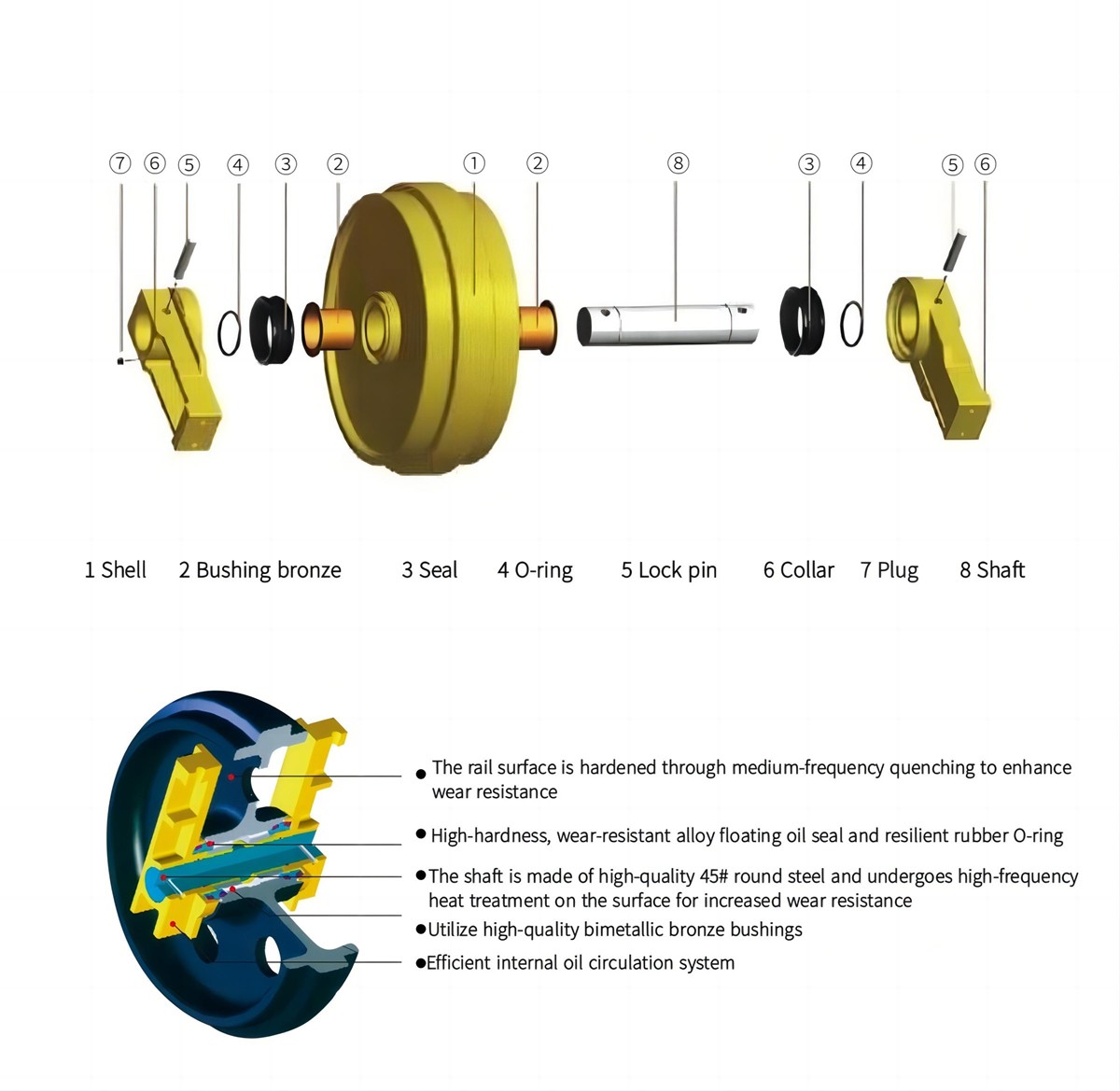

Key Features:

Durable Material: Manufactured from high-strength steel, ensuring excellent wear resistance and durability under extreme operating conditions.

Precision Engineering: Designed to meet or exceed OEM specifications, ensuring a perfect fit and seamless integration with your bulldozer.

Enhanced Performance: This front idler improves track tension and supports optimal track alignment, enhancing overall machine performance and lifespan.

Easy Installation: Comes with all necessary hardware for quick and hassle-free installation, minimizing downtime and boosting productivity.

What is the Detailed Mechanism of the Heat Treatment Process in Improving the Wear Resistance and Hardness of Bulldozer Front Idler?

The detailed mechanism of the heat treatment process in enhancing the wear resistance and hardness of bulldozer front idler mainly involves the following aspects:

Quenching Treatment: Induction quenching is applied to the surface of the front idler, creating a hardened layer that provides sufficient hardness. This treatment significantly improves the wear resistance of the front idler. After quenching, the surface hardness of the parts increases considerably, while the core retains good plasticity and toughness, enhancing impact toughness and fatigue strength.

Tempering Treatment: Through tempering processes (such as annealing or normalizing), the grain structure of the parts can be adjusted to improve their plasticity and toughness. This helps enhance wear resistance while maintaining good mechanical properties.

Material Selection and Optimization: Utilizing high-strength alloy steel containing valuable rare metals such as manganese and chromium, combined with specialized heat treatment processes, ensures that there is sufficient depth in the hardened layer, resulting in high strength and excellent wear resistance.

Surface Hardening Treatment: For example, using medium-frequency surface quenching techniques can achieve surface hardness levels of HRC 55-60, with hardened layer depths reaching 6-8mm. This process significantly increases the strength and wear resistance of the bulldozer front idler wheel.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported