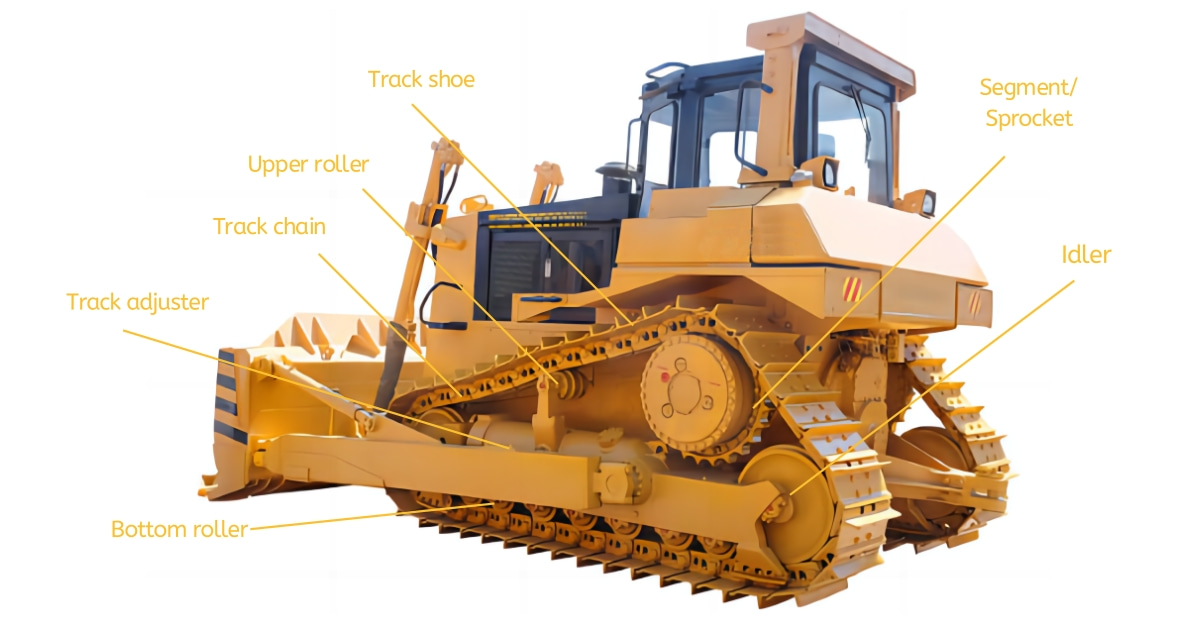

Dozer Undercarriage Parts

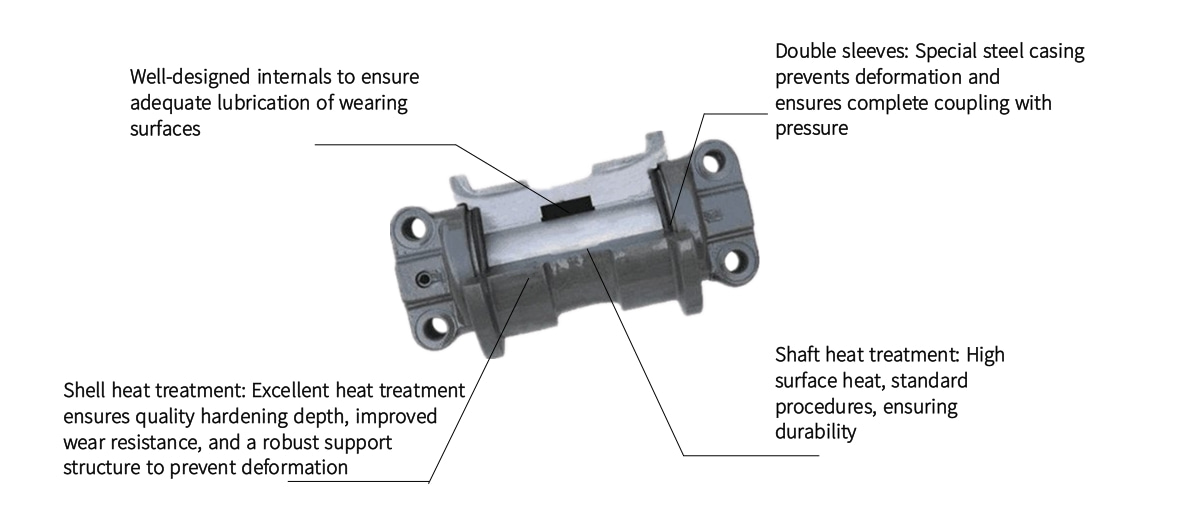

The Bottom Roller for Bulldozer is a crucial undercarriage component designed to support and guide the bulldozer's tracks, ensuring stability and smooth operation even in challenging terrains. Crafted from high-strength alloy steel, it offers exceptional durability, wear resistance, and impact resilience for reliable performance in heavy-duty applications.

Key features:

1.Exceptional Durability: Our Bottom Roller is engineered from high-strength alloy steel, providing exceptional durability and wear resistance to withstand the rigorous demands of bulldozer operations in challenging terrains.

2.Superior Load-Bearing Capacity: The Bottom Roller is designed to efficiently support and guide the movement of the bulldozer's tracks, ensuring stable weight distribution and smooth track operation, even in heavy-duty working conditions.

3.Enhanced Performance: With precision engineering and quality construction, our Bottom Roller contributes to the overall stability and performance of the bulldozer, enabling reliable and efficient operation in various terrains and applications.

4.Impact Resistance: The Bottom Roller is built to withstand impact and shock loads, minimizing wear and extending the service life of the bulldozer's undercarriage, even in demanding work environments.

5.Reduced Maintenance Downtime: Our Bottom Roller's robust design and high wear resistance contribute to reduced maintenance requirements, ensuring prolonged service intervals and minimizing downtime for maintenance and replacements.

6.Compatibility and Customization: Available in a range of sizes and specifications, our Bottom Roller can be tailored to fit various bulldozer models, offering compatibility and flexibility to meet specific equipment requirements.

Why Choose Us

1.Superior Quality: Our products are crafted from high-quality materials and undergo stringent quality control measures to ensure exceptional durability, reliability, and performance, meeting the highest industry standards.

2.Fast Delivery: We understand the importance of timely delivery. With our efficient logistics and streamlined processes, we ensure prompt shipping and delivery, allowing you to receive your orders quickly and efficiently.

3.Outstanding After-Sales Service: Our commitment to customer satisfaction extends beyond the point of sale. We provide comprehensive after-sales support, technical assistance, and responsive customer service to address any inquiries or issues promptly.

4.Unbeatable Value: We offer a compelling combination of top-notch quality and competitive pricing, ensuring that you receive exceptional products at a great value. Our products deliver long-term performance, making them a cost-effective choice for your needs.

5.Customization Options: We understand that every customer's requirements may vary. We offer customization options to tailor our products to your specific needs, ensuring that you get the perfect solution for your equipment.

FAQ

Q: What is the material of your Bottom Roller?

A: Our Bottom Roller is crafted from high-strength alloy steel for exceptional durability and wear resistance.

Q: What is your lead time for delivery?

A: We ensure fast delivery, with typical lead times of 5 days to 3 weeks, depending on order volume and customization requirements.

Q: Do you provide warranty for your Bottom Roller?

A: Yes, we offer a 6-months warranty, ensuring peace of mind and product reliability.

Q: Can you customize the Bottom Roller to fit our specific bulldozer model?

A: Absolutely, we offer customization options to ensure a perfect fit for your bulldozer model.

Q: What is the expected lifespan of your Bottom Roller?

A: Our Bottom Roller is designed for long-term performance, offering exceptional durability and extended service life even in challenging working conditions.

Q: How do you handle after-sales service and support?

A: We provide comprehensive after-sales support, technical assistance, and responsive customer service to address any inquiries or issues promptly.

Bottom Rollers Bulldozer Part Number:

| Model | OEM Part No. |

| D9N/D9R | 7T1253 Bottom Roller |

| D10N/D10R | 6Y0889 Track Roller |

| D31-16 | 113-30-00282 Lower Roller |

| D41-6 | 124-30-52602 Track Roller |

| D50-15/D60-3 | 131-30-00322 Track Roller |

| D60-6 | 141-30-00578 Track Roller |

| D65-12 | 14X-30-00081 Track Roller |

| D80-12 | 154-30-00505 Track Roller |

| D80-18 | 155-30-00126 Track Roller |

| D85E-18 | 155-30-00117 Track Roller |

| D150A-1/D155A-1 | 175-30-00486 Track Roller |

| D155AX-3 | 17A-30-00080 Track Roller |

| D3B/D3C | 6S3607/3T4352 Track Roller |

| D4C/D4D | 7K8096/7K8084 Track Roller |

| D5 | 9S9539 Track Roller |

| D5H | 9P1363 Track Roller |

| D6C | 9S9403 Track Roller |

| D6D | 7G0423/9G8034 Track Roller |

| D6R | 120-5746 Track Roller |

| D6H | 7T4107 Track Roller |

| D7G | 9S0316/4S9051 Track Roller |

| D8N | 9W8706/7G9193 Track Roller |

| D8K | 6P4897/7S9041 Track Roller |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported