Dozer Undercarriage Parts

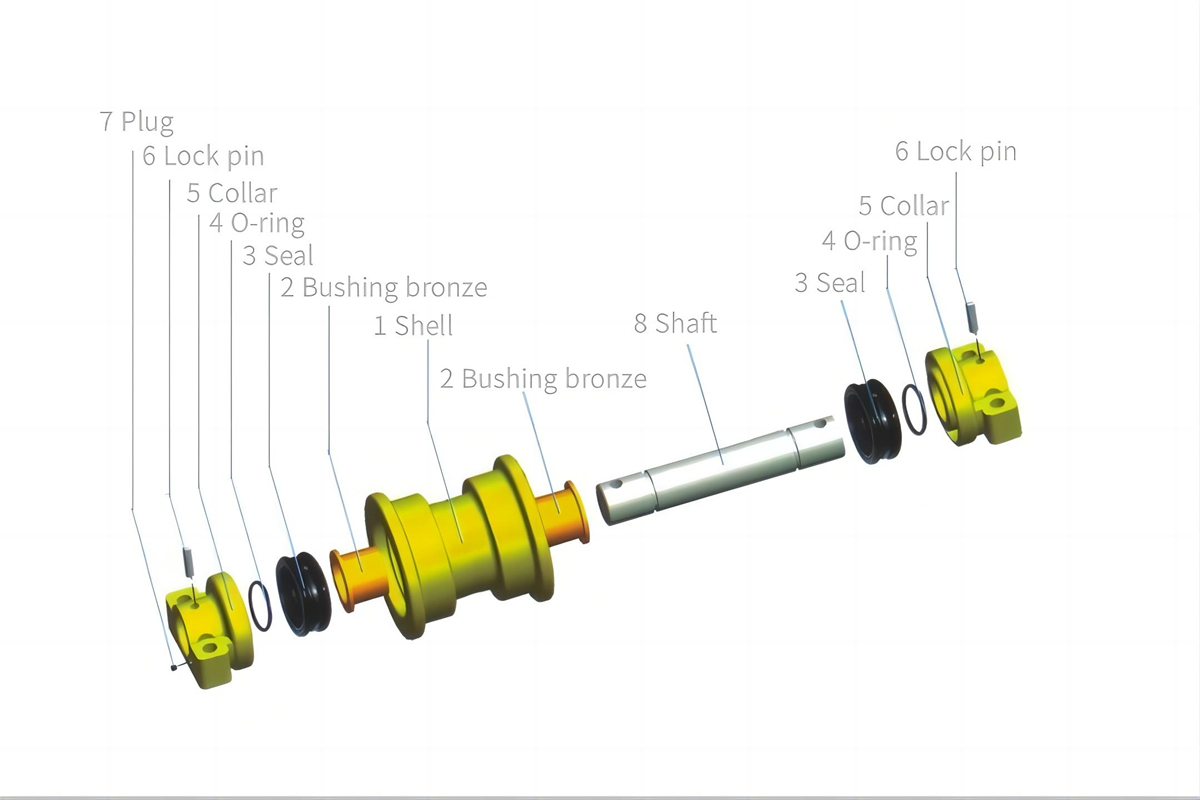

The Bottom Roller, also known as the Track Roller or Lower Roller, is a critical component of the undercarriage system in tracked machinery such as excavators, bulldozers, and loaders. This essential part supports the weight of the machine and facilitates smooth movement over various terrains, ensuring optimal performance and stability during operation.

As a manufacturer with years of specialized experience in producing undercarriage parts, we pride ourselves on our commitment to quality and durability in our Bottom Rollers. Our meticulous selection of high-grade materials ensures that each Bottom Roller is built to withstand the rigors of demanding work environments.

Contact Information:

Material Selection: We prioritize the use of premium materials that enhance the wear resistance and longevity of our Bottom Rollers. This focus on quality materials translates into products that can endure the harsh conditions often encountered in construction and mining operations.

Quality Assurance: Our rigorous quality inspection processes are implemented at every stage of production. We conduct thorough testing to ensure that each Bottom Roller meets our high standards for performance and reliability, minimizing the risk of defects and ensuring consistent quality.

Durability and Reliability: Our Bottom Rollers are engineered for exceptional durability, providing stable support and reducing the frequency of replacements. This reliability is crucial for operators who depend on their machinery for efficiency and productivity.

Expertise and Experience: With years of experience in the industry, we understand the unique challenges faced by our clients. Our expertise allows us to deliver tailored solutions that enhance the performance and longevity of your tracked equipment.

Hardness and Wear Resistance: Proper quenching and tempering can improve the hardness of the bottom roller, thereby enhancing its wear resistance and abrasion capability. For example, appropriate heat treatment of ZG35Cr2SiMnMo low-alloy wear-resistant steel can achieve optimal mechanical properties, reaching a hardness of 53 HRC and demonstrating excellent wear resistance.

Fatigue Life: Heat treatment can also improve the fatigue performance of the material. Studies have shown that by selecting suitable materials and heat treatment processes, such as carburizing and ion nitriding, the bending fatigue life of gears can be significantly increased.

Consistency and Uniformity of Mechanical Properties: By utilizing techniques like induction hardening, the uniformity of the hardness of the bottom roller can be improved, meeting user requirements.

Reducing the Risk of Cracks and Fractures: An appropriate heat treatment process can minimize the risk of delayed cracking caused by quenching stresses. For instance, extending the tempering time and altering the cooling method can effectively address issues related to cracking in batch inner holes.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported