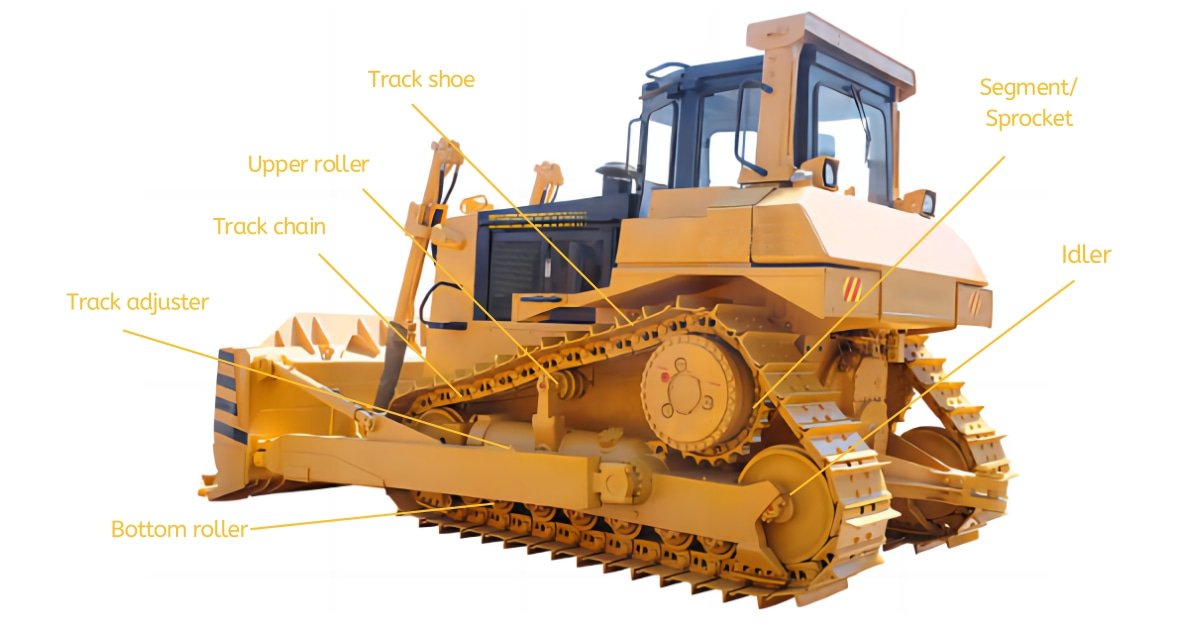

Dozer Undercarriage Parts

As a leading supplier of track link dozers, we pride ourselves on the exceptional level of expertise and professionalism we bring to every aspect of our production. Crafted with superior materials, our track link dozers are renowned for their unrivaled quality, durability, and reliability. Trust in our commitment to delivering products that consistently exceed expectations.

Preventive Measures for Dozer Track Link Looseness:

Regular Inspection and Maintenance: The dozer track link should be regularly inspected and maintained, including cleaning, lubrication, and replacement when necessary. This can effectively extend the lifespan of the chains and reduce the failure rate.

Use of High-Quality Materials: Choose high-quality materials for the links and ensure that all components meet design specifications and standards. This contributes to increased overall durability and reliability.

Optimized Design: Improve the design of the dozer, especially for parts that are easily affected by high loads, such as sprockets and track link connections. Optimizing the design can reduce stress concentration, thereby lowering the risk of fatigue damage.

Adaptive Adjustments: Adjust the operational parameters of the dozer based on different working environments and conditions to accommodate varying work requirements. For example, when working on uneven or hard surfaces, the dozer's speed and power output should be adjusted to reduce additional strain on the chains.

Contact Information:

Email: info@kthpart.com

Whatsapp/ Phone: +86 188 5011 0101

Facebook: https://www.facebook.com/kthpart/

1. Superior Material: Crafted with high-quality materials, our Track Link Dozer is built to withstand the toughest conditions. The carefully selected materials ensure exceptional durability and reliability.

2. Professional Craftsmanship: Meticulously engineered with expert precision, our Track Link Dozer undergoes rigorous manufacturing processes to meet the highest industry standards. Designed by professionals, it guarantees exceptional performance and longevity.

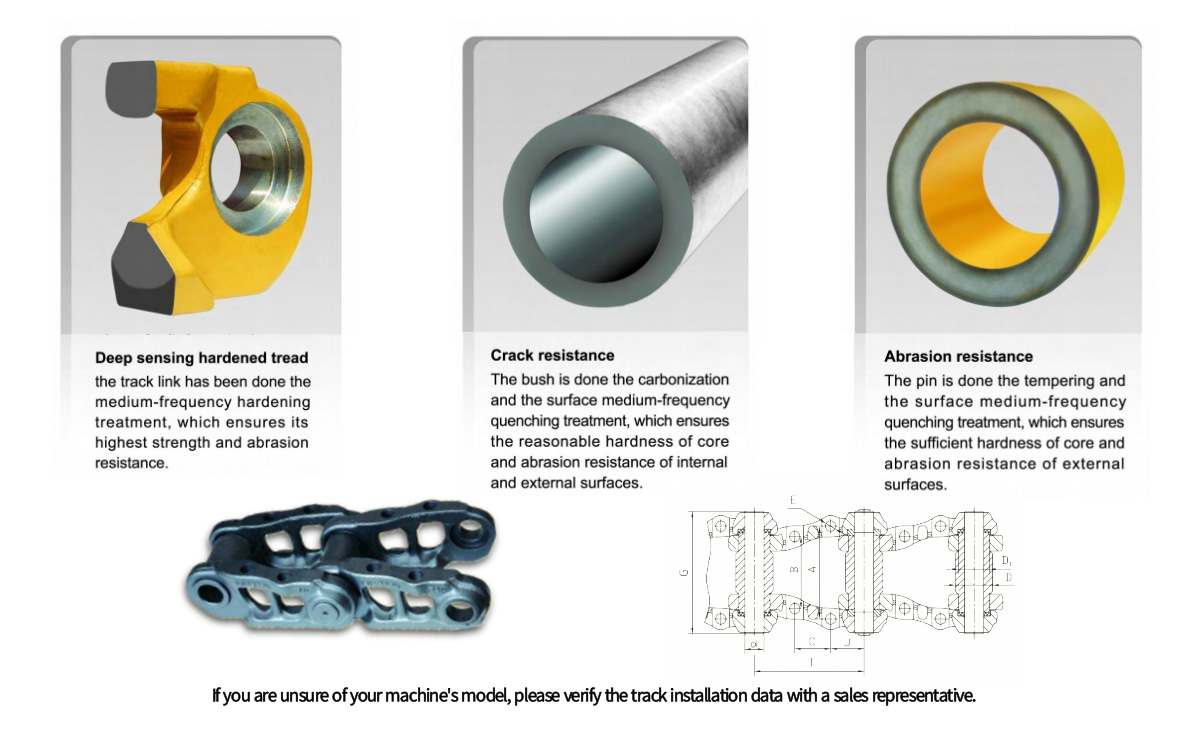

3. Enhanced Hardness and Wear Resistance: Through advanced heat treatment, the track link, track pin, and bush of our Track Link Dozer are significantly improved in terms of hardness and wear resistance. This ensures optimal durability and long-lasting performance, even in the most challenging terrains.

4. Excellent Lubrication Performance: The lubrication system of our Track Link Dozer ensures smooth and consistent operation throughout its usage. It effectively reduces friction, thereby minimizing wear and tear and enhancing the overall efficiency of the machine.

5. Stringent Quality Control: Our Track Link Dozer undergoes strict quality inspections at every stage of the production process. This stringent quality control ensures that each unit meets the highest standards, guaranteeing dependable and consistent product quality.

6. Unparalleled Reliability: With our Track Link Dozer, you can rely on its exceptional performance and longevity. Designed to endure the harshest conditions, it offers unmatched reliability to maximize productivity and minimize downtime.

7. Long-lasting Durability: Engineered to withstand heavy loads and extreme environments, our Track Link Dozer is built for longevity. Its robust construction and superior components enable it to consistently deliver outstanding performance, making it a wise investment for long-term use.

| Model & Part Number | Dozer Track Chain BERCO Number | Links | Pitch |

| D3C 6Y1713 | CR4749/39 | 39L | 155 |

| D4D 7K2372 | CR2567/40 | 40L | 171 |

| D4E 1V7072 | CR3628/36 | 36L | 171 |

| D5 5S0816 | CR2823/39,CR5035/ | 39L | 175 |

| D5B 3P3885 | CR3520/39 | 39L | 175 |

| D5B 953 7T4637 | CR4264/4040 | 40L | 175 |

| D4H 6Y5407 | CR5192/39 | 39L | 171 |

| D5H 6Y5412 | CR5202/37 | 37L | 190 |

| D6D 963 9W8843 | CR4267/36 | 36L | 203 |

| D6C 225 229 6P6131 | CR3176/36,CR5059/ | 36L | 203 |

| D6H 6Y5417 | CR4810A/40 CR6587 | 40L | 203 |

| D6R 6I9670 | CR5534/40 | 40L | 203 |

| D7 977K 1S6943 | CR1769/41 | 41L | 203 |

| D7G 235B 8S2607 | CR2567/38,CR5061 | 38L | 216 |

| 973 9W9167 | CR4700/40 | 40L | 216 |

| D7H 6Y1141 | CR5069/40 | 40L | 216 |

| D8K 2P9492 | CR3149/41 | 41L | 228 |

| D8R 8E4518 | CR4525/44 | 44L | 216 |

| D9H 8S1731 | CR2672/39 | 39L | 260 |

| D10R 2389851 | CR6075/44 | 44L | 260 |

| D20-6,7 102-32-00032 | KM906/37 | 37L | 135 |

| D31P-18,20 11G-32-00025 | KM727/41 | 41L | 154 |

| D61X-12 13G-32-00020 | KM2868/46 | 46L | 190 |

| D65-8 141-32-00045 | KM953/39 | 39L | 203 |

| D65 144-32-00054 | KM951/37 | 37L | 203 |

| D65 141-32-00065 | KM951/39 | 39L | 203 |

| D65PX-15 14Y-32-00110 | KM3467/45 | 45L | 203 |

| D85SS-2 14U-32-00010 | KM2094/42 | 42L | 203 |

| D85-21 154-32-00400 | KM1103/39 | 39L | 216 |

| D85EX-15 154-32-00620 | KM3904/41 | 41L | 216 |

| D155 175-32-00103 | KM325/41 | 41L | 228 |

| D275A-5 17M-32-00400 | KM3593/39 | 39L | 260 |

| D355A-5 195-32-00105 | KM596/39 | 39L | 260 |

| D375A-5 195-32-00591 | KM3599A/40 | 40L | 280 |

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported