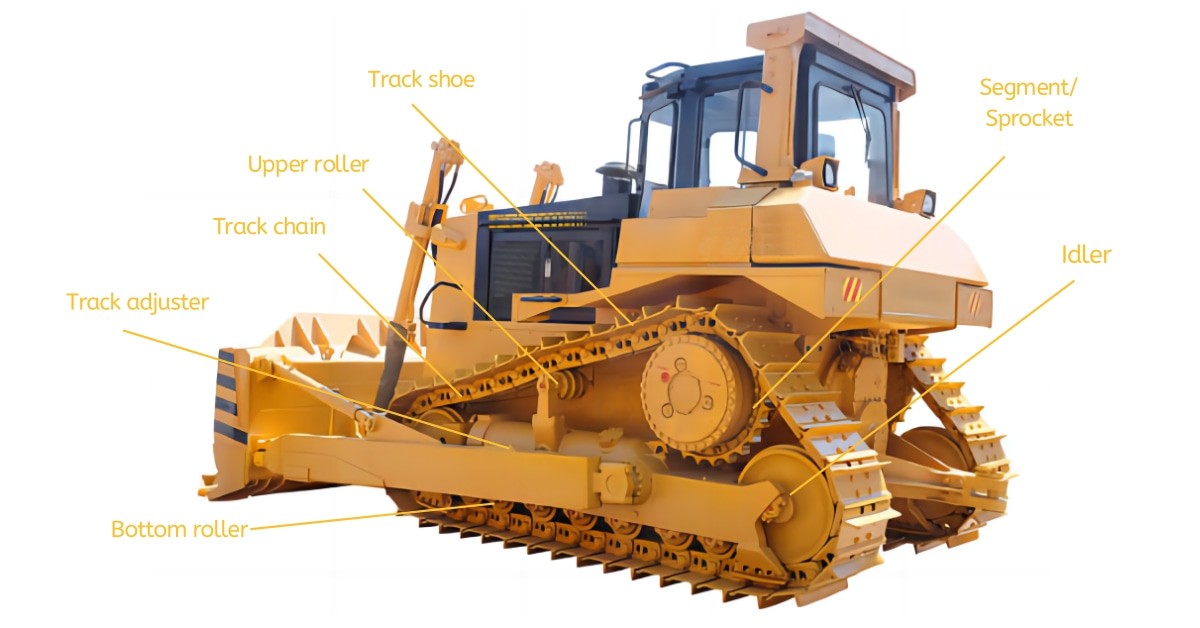

Dozer Undercarriage Parts

The sprocket segment is a crucial component of a bulldozer's undercarriage, responsible for engaging with the track chain to facilitate movement. As a professional manufacturer of dozer undercarriage parts, we take pride in our high-quality sprocket segments. Made from premium materials, our sprocket segments are designed for exceptional durability and wear resistance, ensuring long-lasting performance even in the toughest conditions. We offer a wide range of models to fit various bulldozer brands and specifications, making it easy for you to find the perfect match for your equipment.

As an experienced manufacturer with years of expertise in producing undercarriage parts, we understand the critical importance of quality, durability, and precision in the construction of dozer sprocket segments. Our products are designed to meet the specific needs of global customers, ensuring that they deliver optimal performance and longevity in the toughest working conditions.

When sourcing sprocket segments for your dozer, you need a product that guarantees reliability, durability, and long-term performance. Our sprocket segments are crafted with the highest-quality materials and advanced manufacturing processes to meet these exacting standards.

The foundation of any durable sprocket segment lies in the quality of the materials used. We select only premium-grade steel and alloys for our products, ensuring they can withstand the intense pressures and wear associated with heavy-duty operations. This focus on superior materials not only enhances the longevity of our sprocket segments but also reduces the frequency of replacements, thereby lowering overall maintenance costs.

With many years of specialized production experience, we have perfected our manufacturing processes to produce sprocket segments that meet and exceed OEM standards. Our mature production techniques ensure precision in every detail, resulting in sprocket segments that fit perfectly and operate smoothly. This precision is critical to maintaining the efficiency and performance of your dozer, reducing downtime and increasing productivity.

One of the key factors that set our sprocket segments apart is our advanced heat treatment processes. We employ professional and mature heat processing techniques to enhance the hardness and wear resistance of our sprocket segments. This specialized treatment ensures that our products can endure the harshest environments, providing reliable performance over extended periods.

Our global customers prioritize several key factors when sourcing sprocket segments: material quality, durability, precise fit, and reliable delivery times. We understand these needs and have tailored our production and service processes to meet them effectively. Our sprocket segments are designed with the international market in mind, ensuring they meet the rigorous demands of operators worldwide.

In the fast-paced world of construction and heavy machinery, timely delivery is crucial. We are committed to ensuring that our products reach our customers quickly and efficiently, no matter where they are in the world. Our efficient production and logistics processes enable us to fulfill orders promptly, minimizing downtime for our customers.

Moreover, our commitment to customer satisfaction extends beyond the sale. We offer comprehensive after-sales service, providing support and assistance whenever needed. Whether you require technical advice, installation support, or help with troubleshooting, our dedicated team is always available to ensure you get the most out of our products.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported