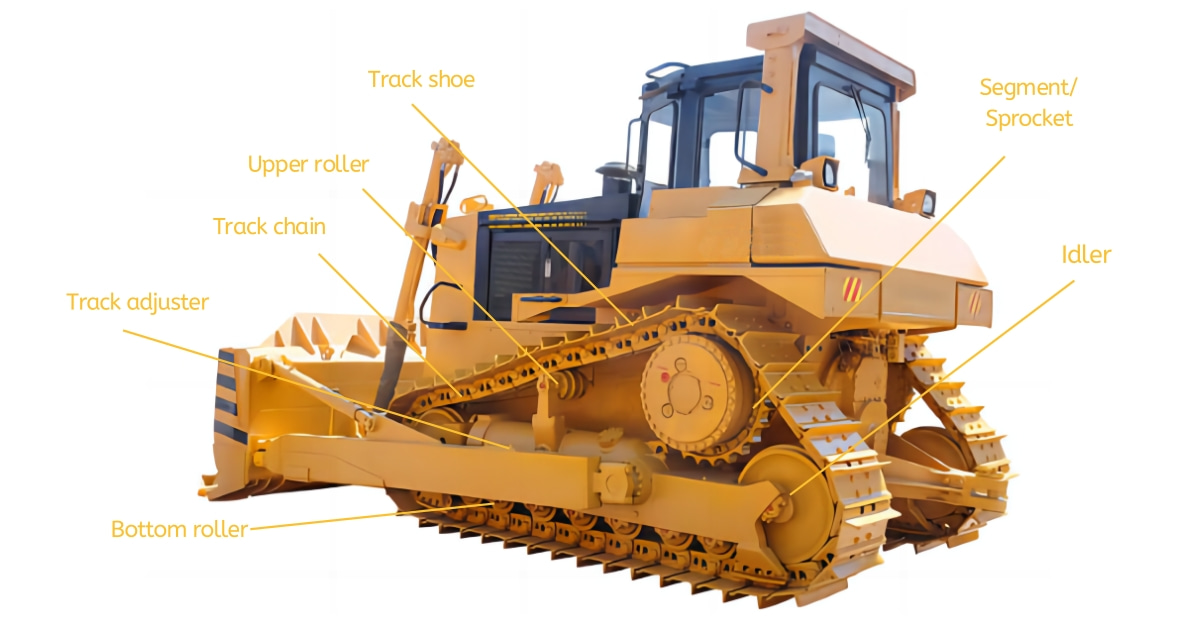

Dozer Undercarriage Parts

A segment dozer is a critical component of a bulldozer’s undercarriage system, composed of individual segments that work together to ensure smooth and efficient track movement. These segments are essential for the proper functioning of the dozer, particularly in heavy-duty applications where precision and reliability are paramount.

The segments in a dozer's undercarriage are vital for distributing the load evenly across the tracks, reducing wear and tear, and maintaining the machine's stability. A well-designed segment dozer ensures that the dozer operates effectively on various terrains, minimizing the risk of track failure and extending the life of the equipment.

Our segment dozers are manufactured using cutting-edge technology and processes that guarantee precision and consistency. We leverage advanced machinery and the expertise of skilled technicians to produce segments that meet the highest industry standards. This meticulous approach ensures that each segment is built to withstand the demands of heavy-duty operations.

We are committed to using only the best materials in the production of our segment dozers. Our material selection process is rigorous, focusing on alloys and metals known for their durability and strength. Our quality control measures are equally stringent, with each segment undergoing thorough inspections and tests to ensure it meets our exacting standards.

Our segment dozers undergo a series of rigorous testing procedures designed to simulate real-world working conditions. These tests assess the segments' resistance to wear, impact, and environmental factors, ensuring they can endure the toughest job sites. This comprehensive testing process guarantees that our customers receive only the most reliable and durable products.

We adhere strictly to international standards in the manufacturing of our segment dozers, ensuring that our products meet or exceed industry benchmarks. This compliance with global standards provides our international customers with the confidence that they are purchasing a product of superior quality that is recognized worldwide.

Our commitment to customer satisfaction continues long after the sale. We offer extensive customer support to assist with any questions or issues that may arise. Our dedicated support team is available to provide technical assistance, troubleshoot problems, and offer guidance on maintenance and repairs, ensuring our customers always have the help they need.

We stand by the quality of our segment dozers with a comprehensive warranty and return policy. Our warranty covers manufacturing defects, offering customers the option to replace or repair faulty segments without hassle. This policy underscores our confidence in the durability and reliability of our products.

We pride ourselves on providing exceptional after-sales service that goes beyond just selling a product. Our support team is dedicated to ensuring that our international clients receive prompt assistance whenever needed. Whether it's providing technical advice, resolving issues, or facilitating access to replacement parts, our after-sales service is designed to give you peace of mind. We are committed to building long-term relationships with our customers, offering continuous support to maximize the efficiency and lifespan of your equipment.

Our segment dozers are engineered for longevity and durability. By choosing our products, customers can expect extended operational life, reducing the need for frequent replacements and minimizing downtime. This durability translates into cost savings and increased productivity on the job site.

In addition to their durability, our segment dozers are also cost-effective. We offer competitive pricing without compromising on quality, making our products an excellent investment for international buyers. The long-term savings from reduced maintenance and replacement costs further enhance the value of our segments.

Our segment dozers are crafted with the highest quality materials, selected through a rigorous process to ensure durability and superior performance. We understand that international buyers demand products that can withstand the toughest conditions. That's why we focus on delivering segments that are not only strong but also designed for long-term reliability. Our commitment to quality ensures that our products perform consistently, even in the most challenging environments.

Our segment dozers are distinguished by their high-quality materials, advanced manufacturing techniques, and rigorous testing processes, ensuring they are both durable and reliable.

We employ stringent quality control measures, including multiple inspections and tests, to ensure that each segment meets our strict specifications and international standards.

We offer a robust warranty that covers manufacturing defects, providing customers with the option to replace or repair faulty segments at no additional cost.

Shipping times vary depending on the destination, but we work with reputable logistics partners to ensure fast and reliable delivery. Detailed tracking information is provided for all orders.

You can contact our customer support team via email or phone for any inquiries or additional information. We are here to assist you with all your needs.

Contact Information:

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported