Dozer Undercarriage Parts

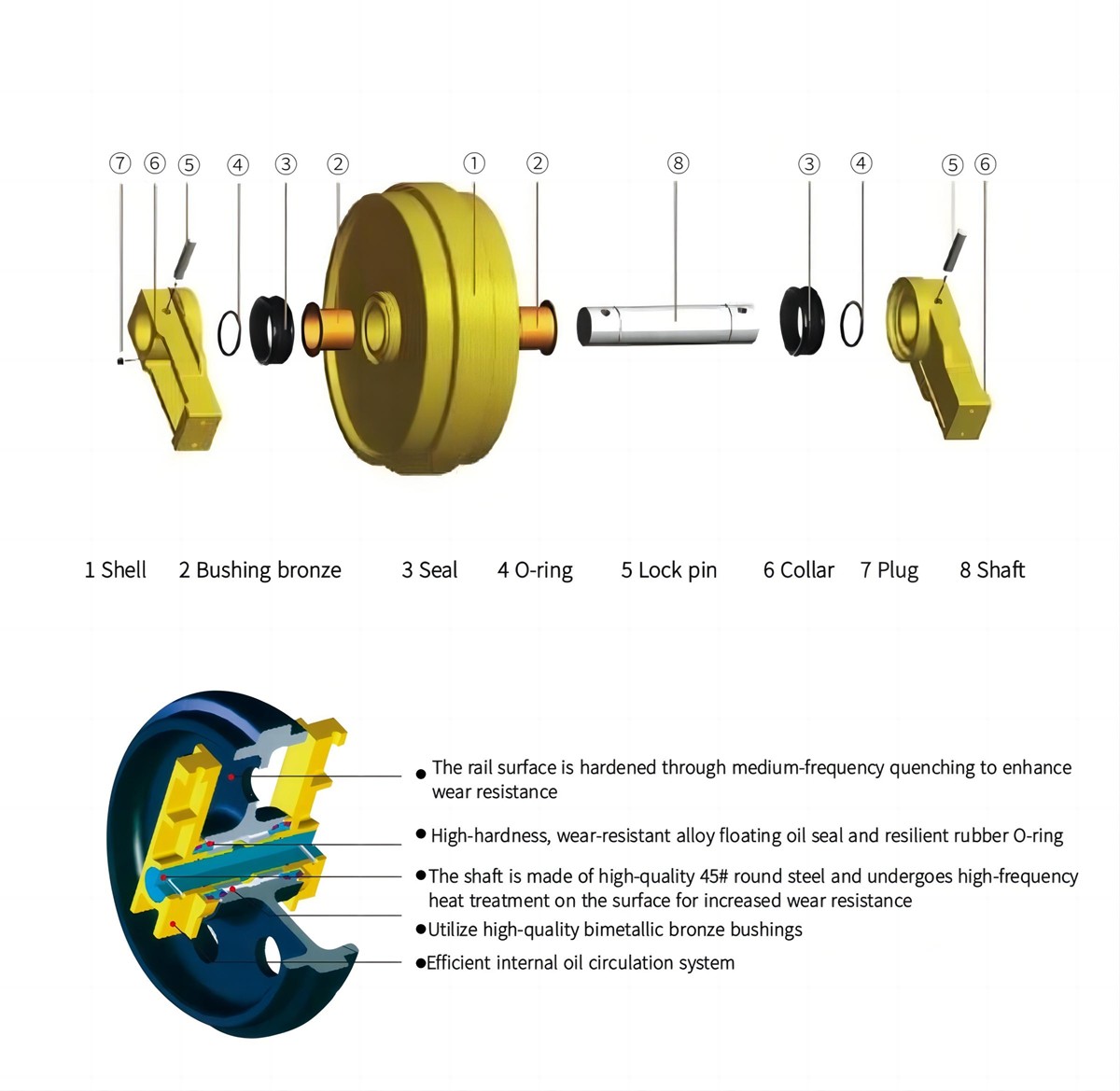

The Front Idler is a vital component of a bulldozer's undercarriage, playing a crucial role in supporting the track system and ensuring smooth operation. Our Front Idler is designed with precision and built to last, utilizing high-quality materials that enhance durability and wear resistance.

As a professional manufacturer, we pride ourselves on our expertise in producing top-tier undercarriage parts. Our Front Idler is engineered to withstand the toughest working conditions, providing reliable performance and longevity. The robust construction minimizes wear and tear, reducing maintenance costs and downtime for your equipment.

With a commitment to quality and performance, our Front Idler is the ideal choice for those seeking dependable and efficient solutions for their bulldozer needs.

The front idler is a critical component of a bulldozer's undercarriage system. It guides the track’s movement, ensuring it remains aligned and tensioned correctly, which is essential for the smooth operation and longevity of the machine. Given its pivotal role, the quality and reliability of the front idler directly impact the overall performance and durability of the bulldozer.

When it comes to purchasing a front idler for a bulldozer, especially in international markets, product quality is paramount. Our front idler bulldozer components are manufactured with the highest quality materials, ensuring they can endure the harshest working conditions. Whether it’s resisting wear and tear, handling extreme temperatures, or maintaining structural integrity under heavy loads, our front idlers are designed for optimal performance.

We employ state-of-the-art manufacturing techniques to produce front idlers that meet the most stringent industry standards. Our production process is overseen by experienced professionals who ensure that every component is manufactured to exact specifications. We use advanced machining and forging processes to achieve the precise dimensions and hardness required for maximum durability and performance.

Our commitment to quality doesn't stop at production. Each front idler undergoes a series of rigorous inspections and tests to ensure it meets our high standards. From material testing to dimensional accuracy checks, we leave nothing to chance. This comprehensive quality control process guarantees that each product delivered to our customers is of the highest quality.

The materials used in our front idler bulldozer components are carefully selected for their strength and resilience. We understand that the durability of these components is crucial for reducing downtime and maintenance costs. By using high-grade steel and advanced alloys, we ensure that our front idlers can withstand the demanding conditions of heavy-duty construction work.

Our front idlers are not just built to perform; they are built to last. With enhanced resistance to wear and corrosion, our products offer extended service life, providing excellent value for money. This longevity means fewer replacements, lower operational costs, and more uptime for your bulldozers.

We understand that the relationship with our customers doesn't end after a sale. We offer robust after-sales support to ensure that your experience with our products is seamless. Our dedicated customer service team is available to answer any questions, provide technical assistance, and resolve any issues that may arise. Whether you need help with installation, maintenance tips, or troubleshooting, we are here to support you every step of the way.

We back our front idler bulldozer components with a comprehensive warranty, reflecting our confidence in their quality and durability. Should any issues arise due to manufacturing defects, our warranty covers repairs or replacements, ensuring that your operations can continue without interruption. Our hassle-free return and replacement policies are designed to give you peace of mind, knowing that we stand behind every product we sell.

Our front idlers have been tested and proven in various demanding environments around the world. Customers choose our products for their reliability, performance, and the peace of mind that comes with knowing they are supported by a company committed to excellence.

We understand that different projects have different requirements. That’s why we offer customizable options to meet your specific needs. Whether you need a specific material, size, or design, our team is ready to provide a solution that fits your exact specifications.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported