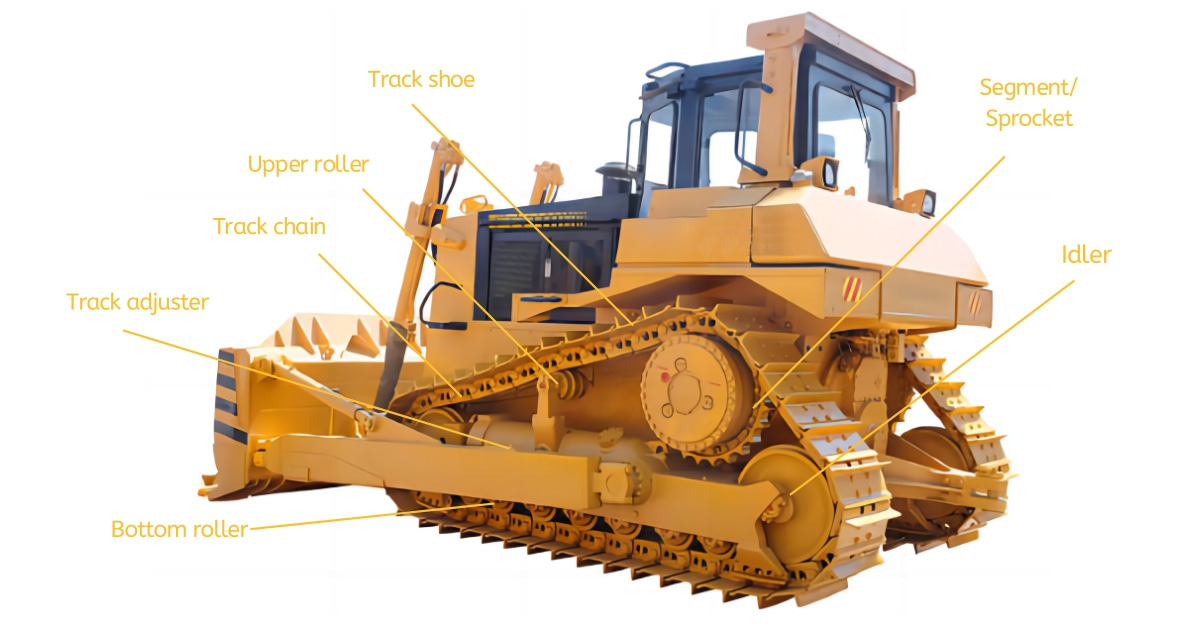

Dozer Undercarriage Parts

The Dozer Track Link Assembly is a critical component of your bulldozer’s undercarriage system. It connects the tracks to the machine, bearing the weight and stress of heavy-duty operations. The quality of the track link assembly directly influences the performance, efficiency, and longevity of your equipment. With years of professional manufacturing experience, we specialize in producing top-quality dozer track link assemblies that stand up to the toughest challenges.

With many years of expertise in manufacturing undercarriage parts, we bring a wealth of knowledge and precision to the production of dozer track link assemblies. Our experience ensures that every component we produce meets the highest standards of quality and performance. We are committed to continuous improvement, applying the latest industry advancements to enhance our production processes.

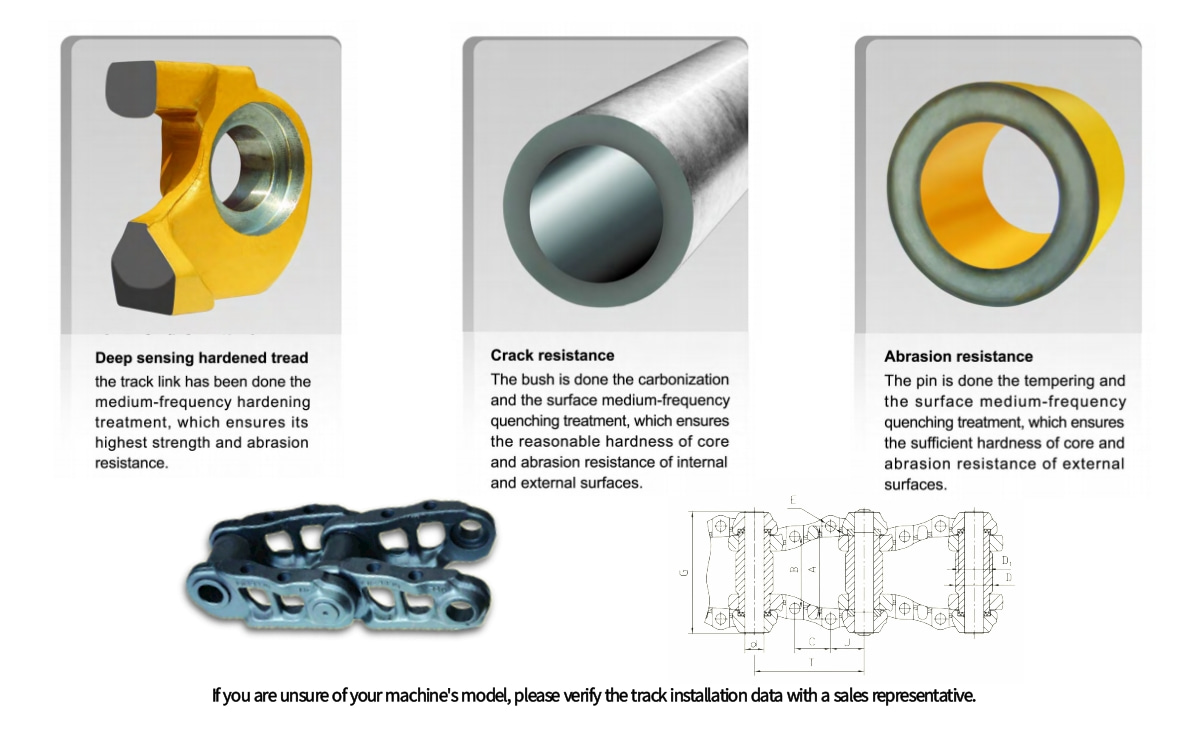

The foundation of a durable and reliable track link assembly lies in the materials used. We carefully select high-grade steel for our track link assemblies, chosen for its exceptional strength, durability, and resistance to wear. This ensures that our products can withstand the intense pressures and harsh conditions that bulldozers often encounter, delivering long-lasting performance in all types of terrain.

Our production process is designed to maximize the quality and durability of our dozer track link assemblies. We employ state-of-the-art manufacturing techniques and continuously invest in the latest technology to improve our processes. This commitment to excellence ensures that our products are not only reliable but also meet the precise specifications required for optimal performance.

One of the key factors in the durability of our track link assemblies is our rigorous heat treatment process. This process significantly enhances the hardness and toughness of the steel, making the assembly more resistant to wear and tear. The result is a product that delivers superior performance and durability, even under the most challenging conditions.

We understand the importance of minimizing downtime for your operations. That’s why we maintain an extensive inventory of dozer track link assemblies, ready for immediate shipment. Our efficient logistics network ensures that your order is processed quickly and delivered on time, no matter where you are located.

Our commitment to customer satisfaction doesn’t end with the sale. We provide comprehensive after-sales support to ensure that you have everything you need to get the most out of your dozer track link assembly. Whether you require technical assistance, maintenance tips, or replacement parts, our dedicated support team is here to help.

Comprehensive Warranty: We offer a robust warranty on our products, reflecting our confidence in their quality and durability. In the unlikely event of an issue, our hassle-free warranty service ensures your needs are met promptly.

Technical Assistance: Our expert team is available to provide guidance and support, helping you with installation, maintenance, and troubleshooting.

Our dozer track link assemblies have been tested and proven in the field, earning the trust of customers around the world. We are proud of our reputation for delivering products that combine quality, durability, and value, making us the preferred choice for those who demand the best.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported