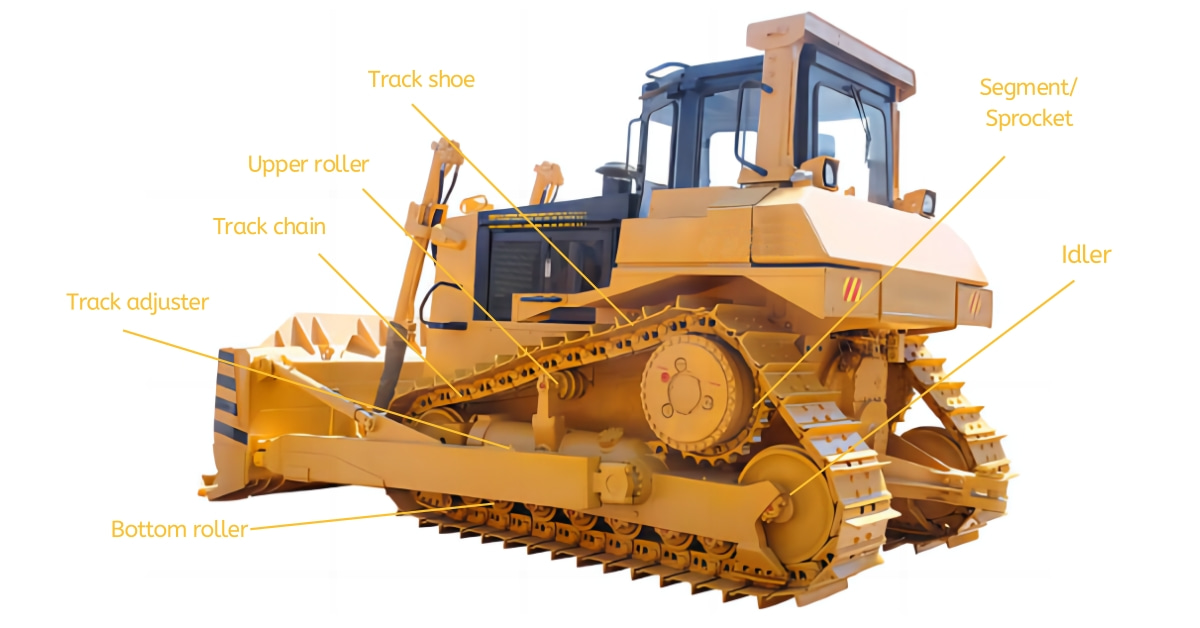

Dozer Undercarriage Parts

Engineered with precision, our product Dozer Top Roller Fit For Caterpillar D8H C61220A 5M7819 7M5202, guarantees optimal performance and enhanced durability, ensuring your machinery effortlessly conquers any challenging terrain. Please feel free to contact us for more information.

Dozer Top Roller Fit For Caterpillar D8H C61220A 5M7819 7M5202 compatible with machine below:

CATERPILLAR

245 583H 983 D8D D8G D8H D8K

LIEBHERR

PR751 R654 R954 R961BHD R962HD R964 R965BHD R971HD R972HD R974 R982LC RL451

D8H Dozer Top Roller part number:

BERCO CR1220A, CR1371A, CR3512

CATERPILLAR 5M7819, 7M5202, 7M5351, 8M0380, 8P6256, 8S6593, 9P2663

LIEBHERR 5209259, 5601508, 5605506

Apart from the quality issues with the dozer top roller, the common causes of dozer top roller damage generally include the following aspects:

Loose Bolts: When the bolts of the walking mechanism are loose, they can easily break or be lost, leading to a series of failures. Therefore, daily maintenance should include checking the installation bolts of the track roller and top roller.

Excessively Loose Track Tension: If the track tension is too loose, the track can easily detach from the track roller and idler, causing the track to lose proper alignment. This misalignment can result in fluctuations, banging, and impacts during operation, leading to abnormal wear on the idler and top roller.

The damage to the dozer top roller must be addressed promptly for the following reasons:

Impact on the Normal Operation of the Walking Mechanism: The top roller plays a crucial role in the bulldozer's walking mechanism. If the top roller is damaged, it can lead to an elongation of the track pitch, resulting in poor engagement between the idler and the bushing. This further causes damage to the bushing and abnormal wear on the drive wheel teeth. In such cases, the bulldozer may exhibit snake tracking, banging, and impacts, significantly shortening the lifespan of the walking mechanism.

Increased Friction and Wear: Damage to the top roller can cause the track to lose proper alignment, leading to fluctuations, banging, and impacts during operation. This not only increases friction but also exacerbates the wear on the top roller and other related components. For example, excessive tension can increase the pressure between the relative moving parts of the walking mechanism, resulting in increased friction and accelerated wear.

Oil Leakage Issues: A damaged top roller may lead to poor sealing, which can result in oil leaks. For instance, oil can leak from between the snap ring and the shaft due to a defective or damaged O-ring; or from between the snap ring and the idler (including the top roller) due to poor contact of the floating seal ring or defects in the O-ring. Oil leakage can adversely affect lubrication and may lead to "burned" bearings, resulting in equipment failure.

Reduced Traction: The damage to the top roller can affect the contact area between the track pads and the ground, resulting in severe wear on the track pads and ultimately leading to a loss of traction for the bulldozer. This presents a serious problem for bulldozers that require high traction for construction tasks.

Therefore, to ensure the normal operation of the bulldozer and extend its service life, the damaged top roller should be replaced immediately upon discovery.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported