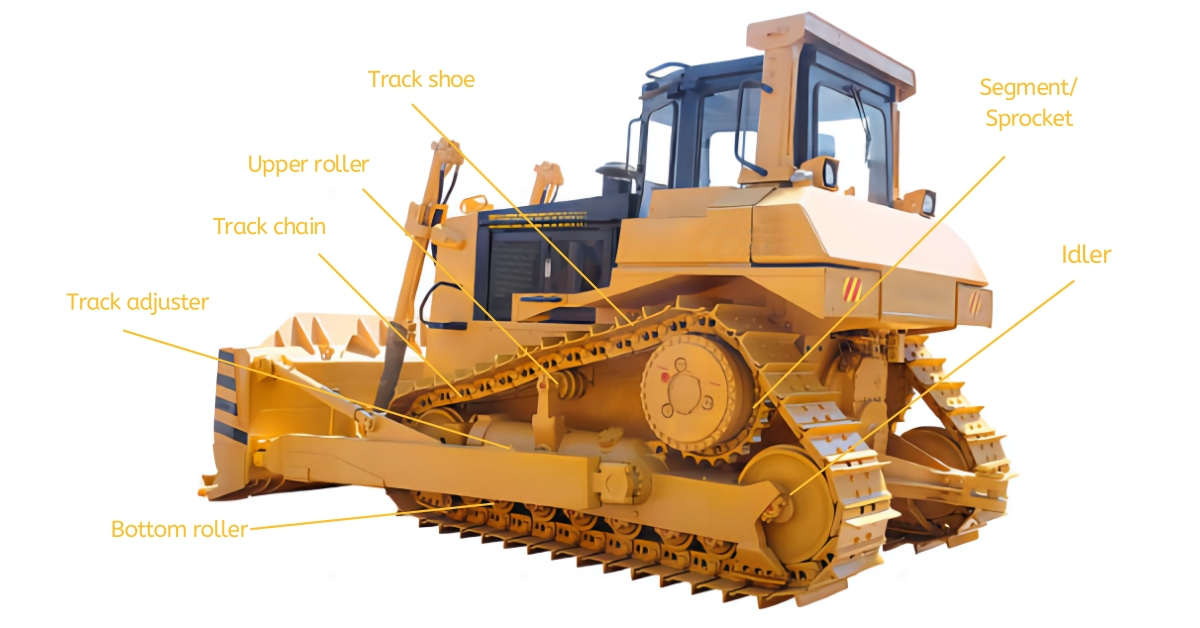

Dozer Undercarriage Parts

Dozer Top Roller CR2205 CR2876 1885600 Fit For Caterpillar D7H Part Number:

ATLAS-TEREX: 1357660

BERCO: CR2205, CR2876, CR4284

CATERPILLAR: 188-5600, 1P8717, 2P3514, 4S8982, 4S9691, 5M7820, 5S3271, 7M9489, 9M0637, 9M0638

HYUNDAI: 81E7-0016, 81E7-00521,81E7-00522

ITM: C0107100M00

KOMATSU ALL MAKES: ZZYR0024

LIEBHERR 5000951, 5002789, 5604047, 5604175, 5800083

Suitable for, but not limited to, the following models of bulldozers or crawler loader:

Caterpillar:

235, 235B, 235C, 235D, 571F, 571G, 572G, 973C, 977H, 977K, 977L, D7, D7D, D7F, D7G, D7H, D7R

HYUNDAI:

R350, R350LC, R360LC, R420, R450LC, R480LC-9, R500LC, R520LC-9

JOHN DEERE

950C, 950C LGP

LIEBHERR

HS840, PR741, PR742, PR744LGP, R942HD, R945, R952 , R954, R961, R962LC, R965B, SR741

How to Effectively Reduce Wear on the Dozer Top Roller During Frequent Location Changes and Long-Distance Travel?

To effectively reduce wear on the dozer top roller when the bulldozer frequently changes work locations and travels long distances, the following measures can be taken:

Reasonably Select Work Locations and Optimize Work Routes: Before selecting a construction site, conduct a detailed survey of the terrain to understand geological conditions, soil properties, and the surrounding environment, avoiding factors that are unfavorable for bulldozer operations. By reasonably planning the work route to reduce the number of turns and travel distance during operations, the vibrations and friction experienced by the bulldozer during travel can be significantly reduced, thereby decreasing wear on the top roller.

Adjust Track Tension: Track tension is one of the main causes of chassis wear. It is essential to adjust the track tension according to different conditions; for example, after rain, it may be necessary to readjust the tension. Refer to the operation and maintenance manual to ensure the machine operates at the correct working tension, and extend the undercarriage's lifespan by regularly changing and testing the tension.

Segmented Operations: When faced with long-distance bulldozing tasks, it is advisable to perform segmented operations from the front to the back. Each segment should be just enough to fill with material, allowing the bulldozer to push one segment and then move back to the next. This method can reduce the distance the bulldozer travels while fully loaded and also minimize the distance it travels empty on the return, thus reducing wear on the top roller.

Avoid Sharp Turns: Sharp turns can put greater pressure on the dozer top roller, accelerating wear. Therefore, during operations, sharp turns should be avoided as much as possible, and care should be taken to ensure that the turning angle is not too large.

Regular Maintenance and Inspection: Performing daily inspections is a simple yet effective step, as it allows you to understand the operational condition of the equipment and identify and address potential issues in a timely manner. Additionally, it is necessary to regularly lubricate components such as hinges, connection areas, and wheel transport pivots.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported