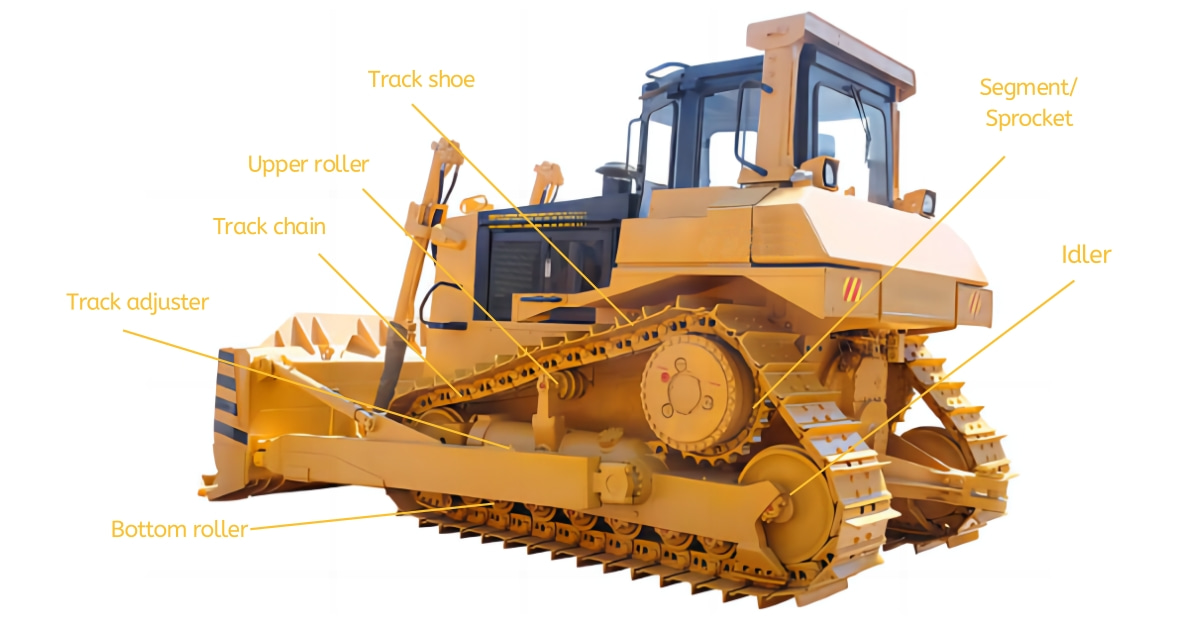

Dozer Undercarriage Parts

Crafted with precision and unparalleled efficiency, Engineered to perfection, the Dozer Sprocket Fit For Caterpillar D8N D8R D8T CR4477 1146413 guarantees a seamless integration with your heavy machinery, ensuring optimum performance and longevity.

Dozer Sprocket Fit For Caterpillar D8N D8R D8T Part Number:

CR4477, CR4539, CR5049A, 1146413, 1629534, 1730947, 1730948, 3145462, 6T3197,6Y2354, 7T-9773

D8N D8R D8T dozer sprocket bolts Part Number:

BERCO CR4145, CR4478 s, 5P4130 , 5P7665, ITM S01082K0N16

D8N D8R D8T dozer sprocket nuts Part Number:

BERCO CR787 , 7H3608, ITM S01072D0N17, LIEBHERR 7002394, LIEBHERR 7401287

The Importance of Evaluating Dozer Sprocket Wear

The dozer sprocket is a crucial component of dozer undercarriage parts and is also a wear-prone consumable. Timely assessment of the wear condition of the dozer sprocket is essential. Evaluating the wear resistance and service life of bulldozer dozer sprockets requires a comprehensive consideration of multiple factors, including material selection, heat treatment processes, and actual operating environments.

From the perspective of material selection, dozer sprockets are typically made from high-strength alloy steel, containing valuable metals such as manganese, chromium, and molybdenum. These components significantly enhance the hardness and wear resistance of the sprockets. For example, the dozer sprockets from our company undergo complete forging and heat treatment, ensuring that the tooth surface maintains high hardness while the core also exhibits good hardness, thereby improving the product's wear resistance and service life.

The heat treatment process also plays a vital role in the wear resistance of the sprockets. For instance, medium-frequency tempering can create a sufficient hardened layer on the tooth surface, enhancing its wear resistance. Additionally, dozer sprockets that undergo surface hardening treatment can further increase their hardness and wear resistance.

The actual operating environment is another important factor in assessing the wear resistance and service life of the sprockets. In harsh working conditions, such as pushing on hard rock or metal surfaces, the wear and damage to the sprockets can be accelerated. Therefore, when designing and installing sprockets, efforts should be made to avoid these adverse conditions to extend their service life.

Moreover, field test data can provide valuable reference information.

In summary, evaluating the wear resistance and service life of dozer sprockets requires a comprehensive consideration of material selection, heat treatment processes, and actual operating environments.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported