Dozer Undercarriage Parts

Dozer Bottom Roller Single Flange CR2617 1181623 1248250 Fit For Caterpillar D7F D7G D7H D7R

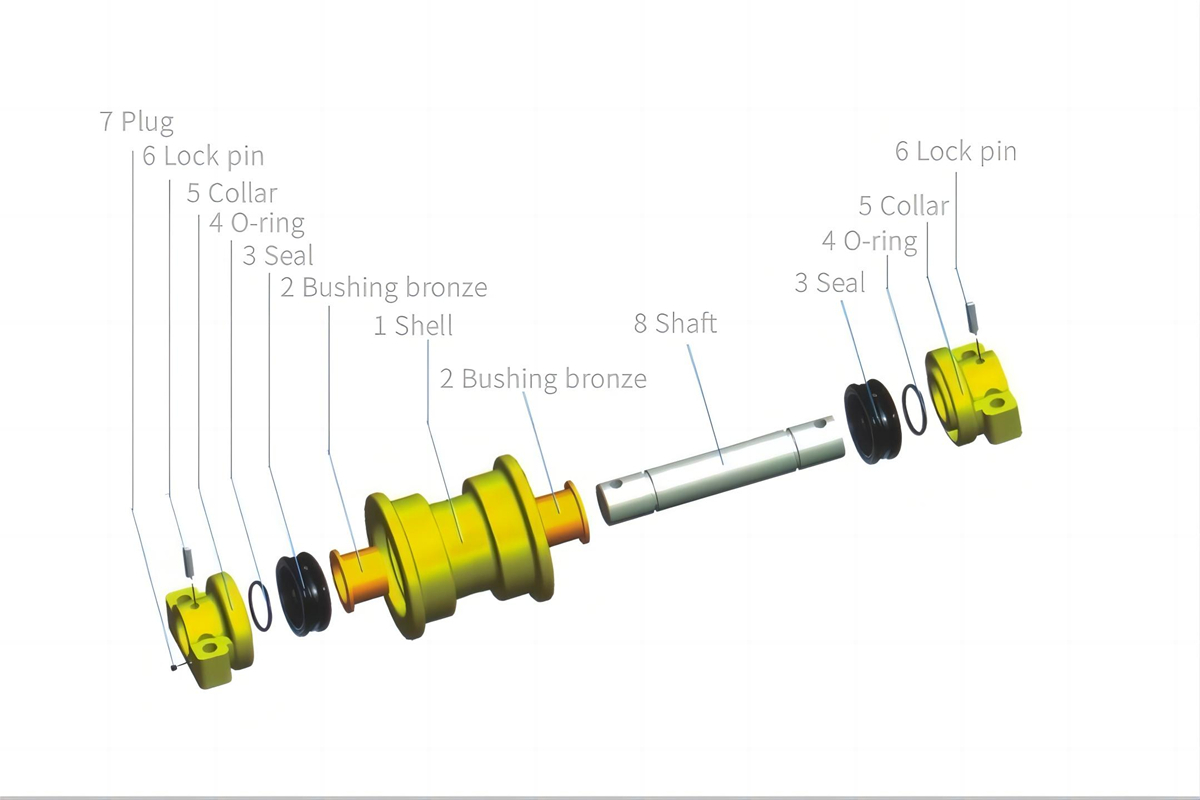

Designed to withstand the most demanding terrains and rigorous work conditions, the Dozer Bottom Roller Single Flange CR2617 1181623 1248250 Fit For Caterpillar D7F D7G D7H D7R guarantees exceptional performance and longevity. Its sleek design and advanced engineering provide unparalleled stability, allowing for smoother and more efficient operation.

Dozer Bottom Roller Single Flange CR2617 1181623 1248250 Fit For Caterpillar D7F D7G D7H D7R

D7F D7G D7H D7R Dozer Bottom Roller Single Flange Part Number:

BERCO: CR2617, CR2617A, CR2617B

CATERPILLAR: 118-1623, 124-8250, 125-4178, 323-5925, 3P1520, 3P6062, 4S9050, 4S9051, 6T9871, 9S0316

ITM A01070A1M00

LIEBHERR: 5002787, 5603031, 7405220

The main difference between the dozer bottom roller single flange and dozer bottom roller double flange lies in their internal structure and quantity. Generally, the number of double flange track rollers on a bulldozer is less than that of single flange bottom rollers. The internal structure of the dozer bottom roller double flange is similar to that of thedozer bottom roller single flange, but to avoid excessive rolling resistance during the operation of the bulldozer, double flange track rollers are typically used in applications that require higher stability and load-bearing capacity.

When selecting between the two, one should consider the specific construction environment and requirements to ensure that the bulldozer can perform optimally. For instance, when operating on saturated soil, the double flange bottom roller, due to its higher stiffness and stability, can better prevent soil from clogging and hindering movement.

As to whether dozer bottom roller single flange and double flange bottom rollers can be interchanged, it depends on the specific application scenario and requirements. If the construction environment does not demand high stability and there is a need to simplify the structure and reduce costs, dozer bottom roller single flange may be chosen. Conversely, if the working environment is complex and requires higher stability and durability from the equipment, double flange bottom rollers should be selected. Therefore, the two are not completely interchangeable and should be chosen based on the actual circumstances.

Specific Structural Differences between dozer bottom roller single flange and dozer bottom roller double flange:

The structure of dozer bottom rollers can be divided into single-sided and double-sided track rollers, each having some specific structural differences.

Flange Design:

Single flange Bottom Roller: Has a raised edge only on one side of the flange (inner or outer).

Double flange Bottom Roller: Has raised edges on both the inner and outer sides of the flange, which helps better grip the track.

Rolling Resistance:

Single flange Bottom Roller: With a raised edge in only one direction, it experiences relatively low rolling resistance.

Double flange Bottom Roller: With raised edges in two directions, it has higher rolling resistance.

Load-Bearing Capacity:

Single flange Bottom Roller: Generally used for bulldozers with lower power, due to its simple structure and lower manufacturing costs.

Double flange Bottom Roller: Typically used for more powerful bulldozers, as it provides better support and stability.

Materials and Processes:

The materials for the roller body of dozer bottom roller Single flange and double flange rollers of equal quality and price are generally not significantly different; the main processes involve casting or forging, followed by machining to finalize the product.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported